Laver automatic processing production line and processing method thereof

A production line and seaweed technology, applied in application, food processing, food science, etc., can solve the problems of general work efficiency, long working hours, and low production efficiency, and achieve the effect of long working hours, high production costs, and reduced hygiene problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

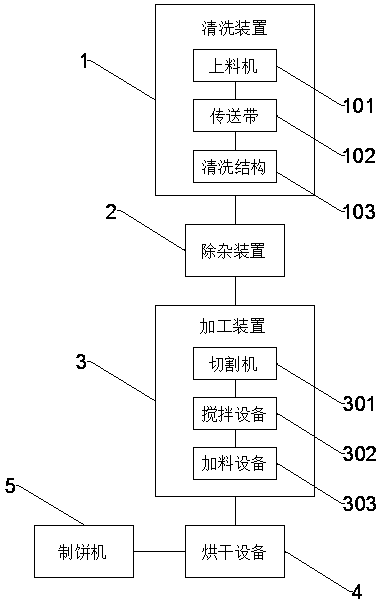

[0029] An automatic laver processing production line, the processing production line includes: a cleaning device, an impurity removal device, a processing device, a drying device and a cake making machine.

[0030] Wherein, the cleaning device includes a feeder, a conveyor belt and a cleaning structure.

[0031] Wherein, the processing device includes a cutting machine, a stirring device and a feeding device.

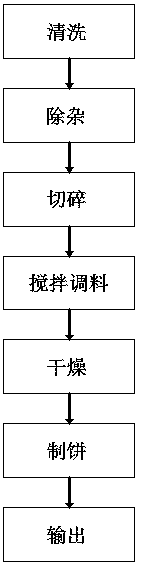

[0032] A laver automatic processing production line, wherein the specific processing method of the automatic processing production line comprises the steps:

[0033] S1 Cleaning: Put the laver raw materials into the feeder of the cleaning device, and the feeder sends the laver raw materials into the cleaning structure through the conveyor belt for washing, and washes and removes the salt stains on the laver and the large particles mixed in the raw materials impurities;

[0034] S2 Impurity removal: send the laver raw material treated in step S1 to the impurity removal...

Embodiment 2

[0045] An automatic laver processing production line, the processing production line includes: a cleaning device, an impurity removal device, a processing device, a drying device and a cake making machine.

[0046] Wherein, the cleaning device includes a feeder, a conveyor belt and a cleaning structure.

[0047] Wherein, the processing device includes a cutting machine, a stirring device and a feeding device.

[0048] A laver automatic processing production line, wherein the specific processing method of the automatic processing production line comprises the steps:

[0049] S1 Cleaning: Put the laver raw materials into the feeder of the cleaning device, and the feeder sends the laver raw materials into the cleaning structure through the conveyor belt for washing, and washes and removes the salt stains on the laver and the large particles mixed in the raw materials impurities;

[0050] S2 Impurity removal: send the laver raw material treated in step S1 to the impurity removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com