Manual-automatic winding type filter

A filter and winding technology, applied in the field of air purification, can solve the problem that the filter cannot be used normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

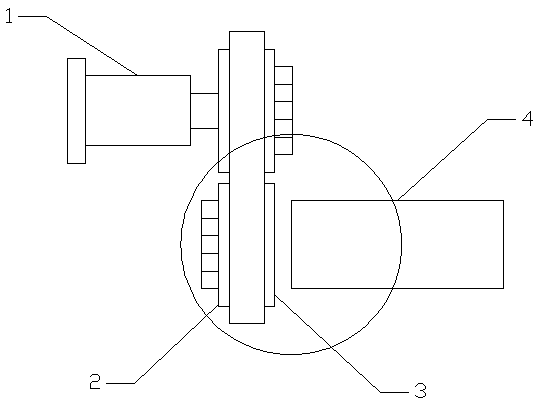

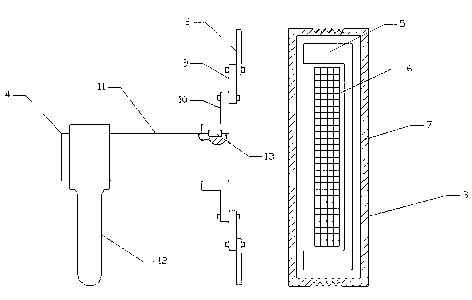

[0012] Embodiment 1: see figure 1 , figure 2

[0013] The basic structure of the hand-automatic winding filter of this embodiment includes a filter material frame supporting the filter material, a driven filter material reel and an active filter material reel 4 are respectively installed at the upper and lower ends of the filter material frame, and the active filter material reel 4 as figure 1 Shown is connected with the drive part 2 by a clutch 3, and the drive part 2 is connected with the drive motor 1 by an engagement transmission, and a handle 12 is installed on the active filter material reel 4. Clutch 3 is a clutch with connecting and disconnecting functions. The meshing drive connection may be a chain drive connection. The clutch can be a magnetic powder clutch or an electromagnetic clutch. Turn on the power switch clutch 3 to connect the filter material reel 4 and the driving part 2, and the filter runs automatically. Turn off the power switch, the driving motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com