Device for filtering and separating flow media

A technology of flowing medium and separation unit, applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of high cost disassembly, cleaning, resealing and reassembly, unreliability, etc., to reduce leakage. Possibility, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

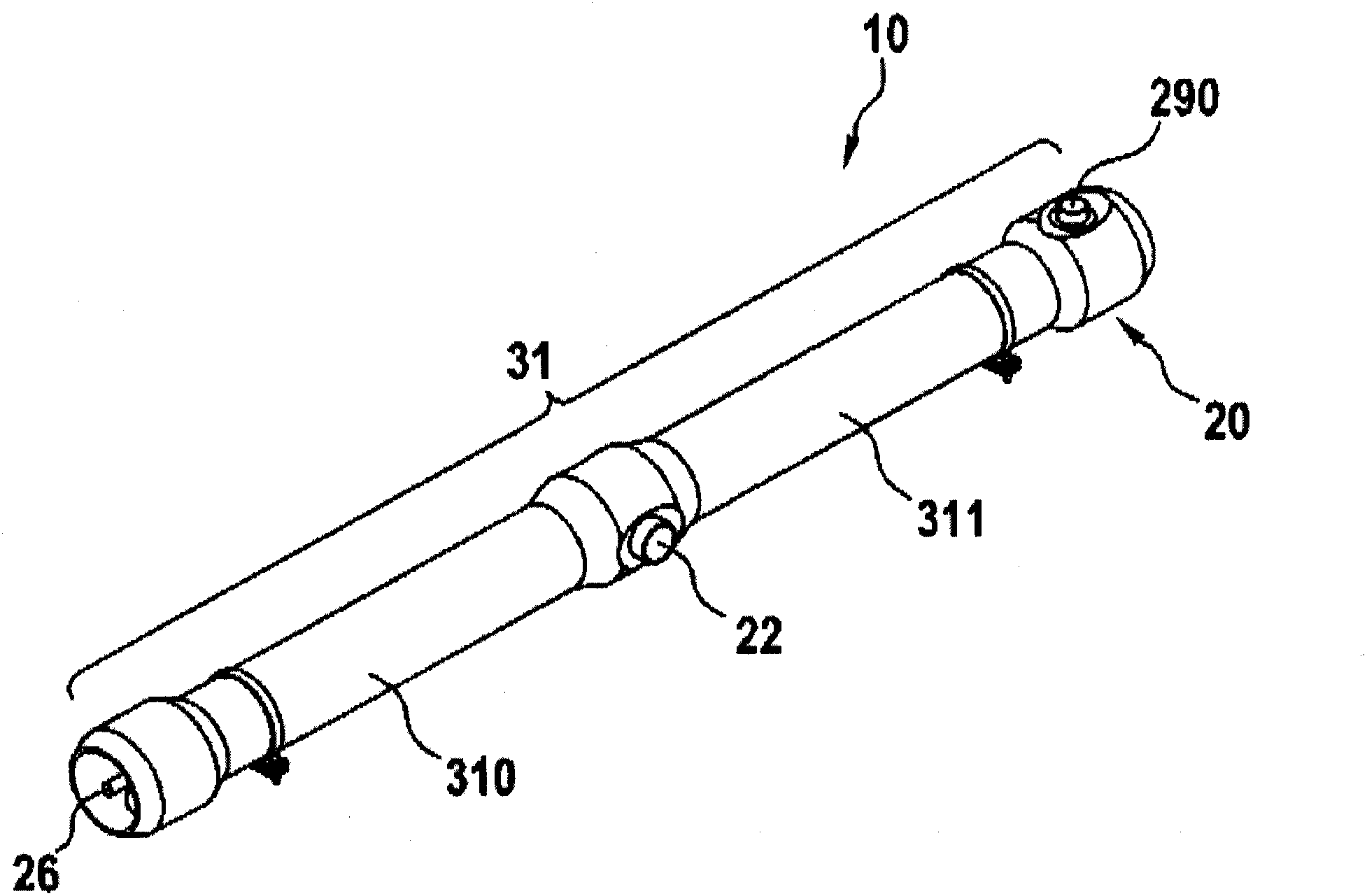

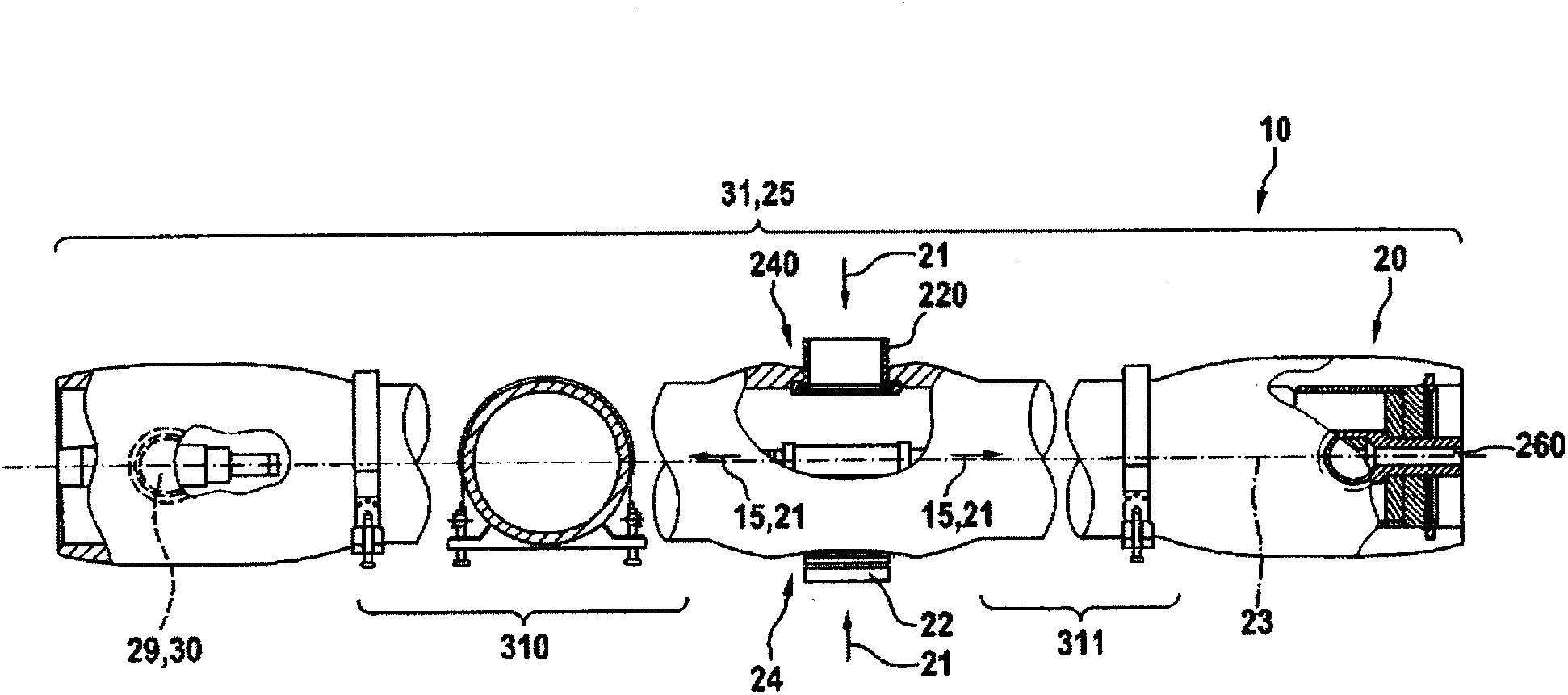

[0031] To illustrate the basic construction of the device 10, first refer to figure 1 and figure 2 .

[0032] figure 1 The figure shows a perspective view of the container 20 of the device 10 , wherein the container housing 31 is divided into two container housing elements 310 , 311 . In each of the container housing elements 310, 311 is accommodated a separation unit 11, 110, wherein the separation units 11, 110 generally have the same construction, but the following solution of the device 10 is also possible, that is, the separation unit 11, 110 The separation units 11 , 110 each have different separation specifications for the flow medium 21 , often referred to as fluid or “feed”, which is of different construction and is introduced jointly into the inlet 22 of the two separation units 11 , 110 .

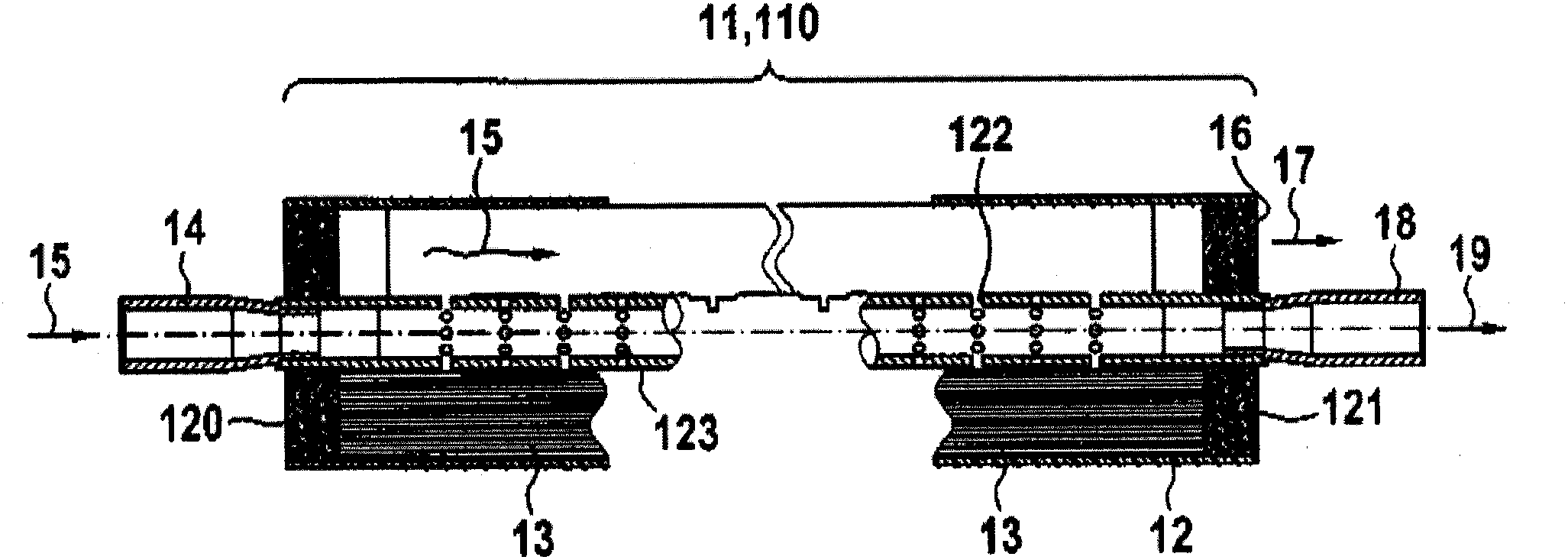

[0033] as in figure 2 The basic construction of the separation unit 11, 110 is known, as exemplified in figure 2 The separation units 11, 110 described in are equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com