Method for obtaining high-pressure steam through absorbing heat from low-pressure steam

A technology of high-pressure steam and low-pressure steam, applied in steam generation, lighting and heating equipment, sustainable manufacturing/processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

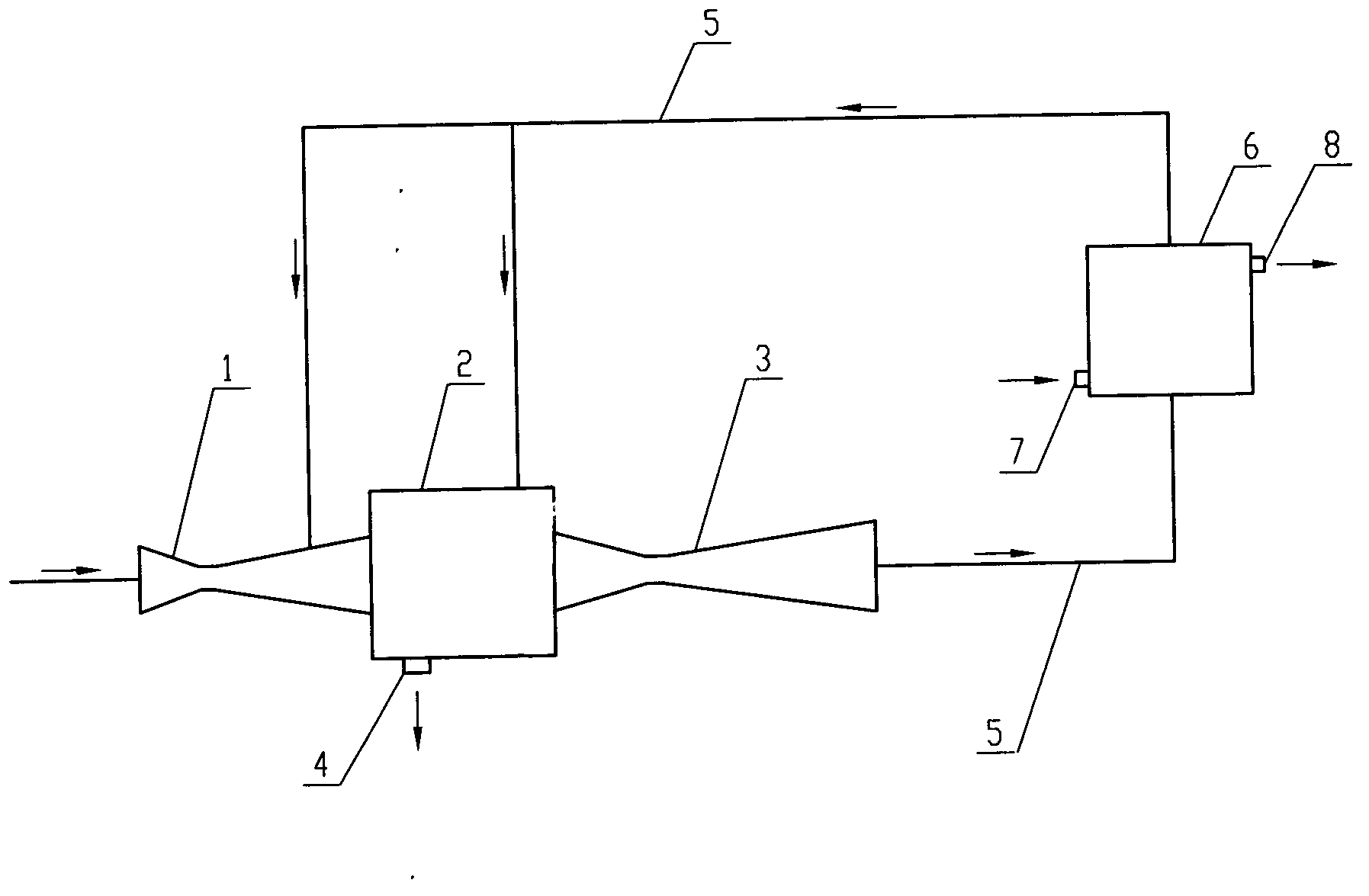

[0010] Referring to the accompanying drawings, the present invention is a process for absorbing heat from low-pressure steam to obtain high-pressure steam, which includes an expansion tube 1, a heat exchanger 2, a diffuser tube 3, a condensate outlet 4, a steam pipeline 5, and a high-pressure steam generator 6 , High-pressure water supply inlet 7, high-pressure steam outlet 8.

[0011] The expansion tube 1 is a conical tube structure, and the steam expands and cools down in the tube. The inlet end of the expansion tube 1 is connected to the steam pipeline 5, the outlet end of the expansion tube 1 is connected to the expansion steam inlet end of the heat exchanger 2, and the middle part of the expansion tube 1 is connected to the low-pressure steam outlet of the high-pressure steam generator 6 through the steam pipeline 5;

[0012] The heat exchanger 2 is provided with a heat exchange tube, the expansion steam is passed into the tube, and the heating steam is passed into the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com