Improved desk type lens dyeing device

A kind of dyeing equipment and improved technology, which is applied in the field of improved desktop lens dyeing equipment, can solve the problems of not installing ventilation and lighting systems, not being able to dye progressive color lenses, limitations and uneven heating, etc., to enhance market competitiveness , Consistent dyeing depth, the effect of meeting the customized requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

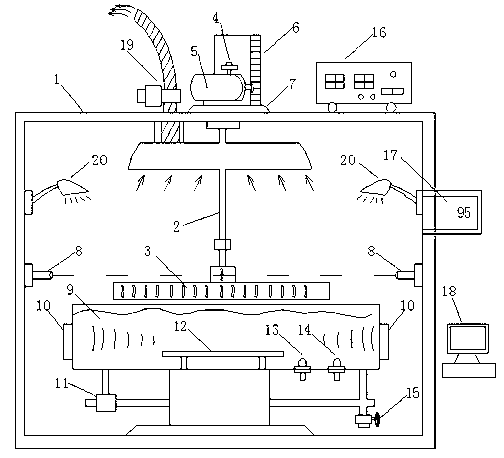

[0017] refer to figure 1 , an improved desktop lens dyeing equipment, including: including a frame 1, a moving body of the dyeing equipment, a pendant rack 2 and a constant temperature dyeing tank 9, a pendant frame 2 and a pendant basket 3 are installed in the center of the upper frame of the frame 1, and the center of the upper part of the frame Install the fixed seat 7, the side of the fixed seat 7 is installed with the servo motor 5 and the displacement sensor 4, and the lifting gear column guide rail 6 is installed in the middle, and the lower end of the servo motor 5 is connected with the pendant rack 2 to realize linkage lifting; The lower end is snap-locked on the fastening piece, which is convenient to put in and take off; the dyeing degree detection device 8 transceiver devices are installed on the left and right sides of the middle part of the frame 1, and its outgoing light is designed to just pass through the hanger basket 3 hovering in the air The middle part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com