Single-side printed circuit board with ultrahigh heat conducting performance and manufacturing method thereof

A printed circuit board, thermal conductivity technology, applied in the direction of printed circuit, circuit substrate material, printed circuit manufacturing, etc., can solve the problems of limited heat dissipation, copper thickness and unevenness of PCB warping line, etc., to improve stability and Reliability, good heat conduction effect, effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

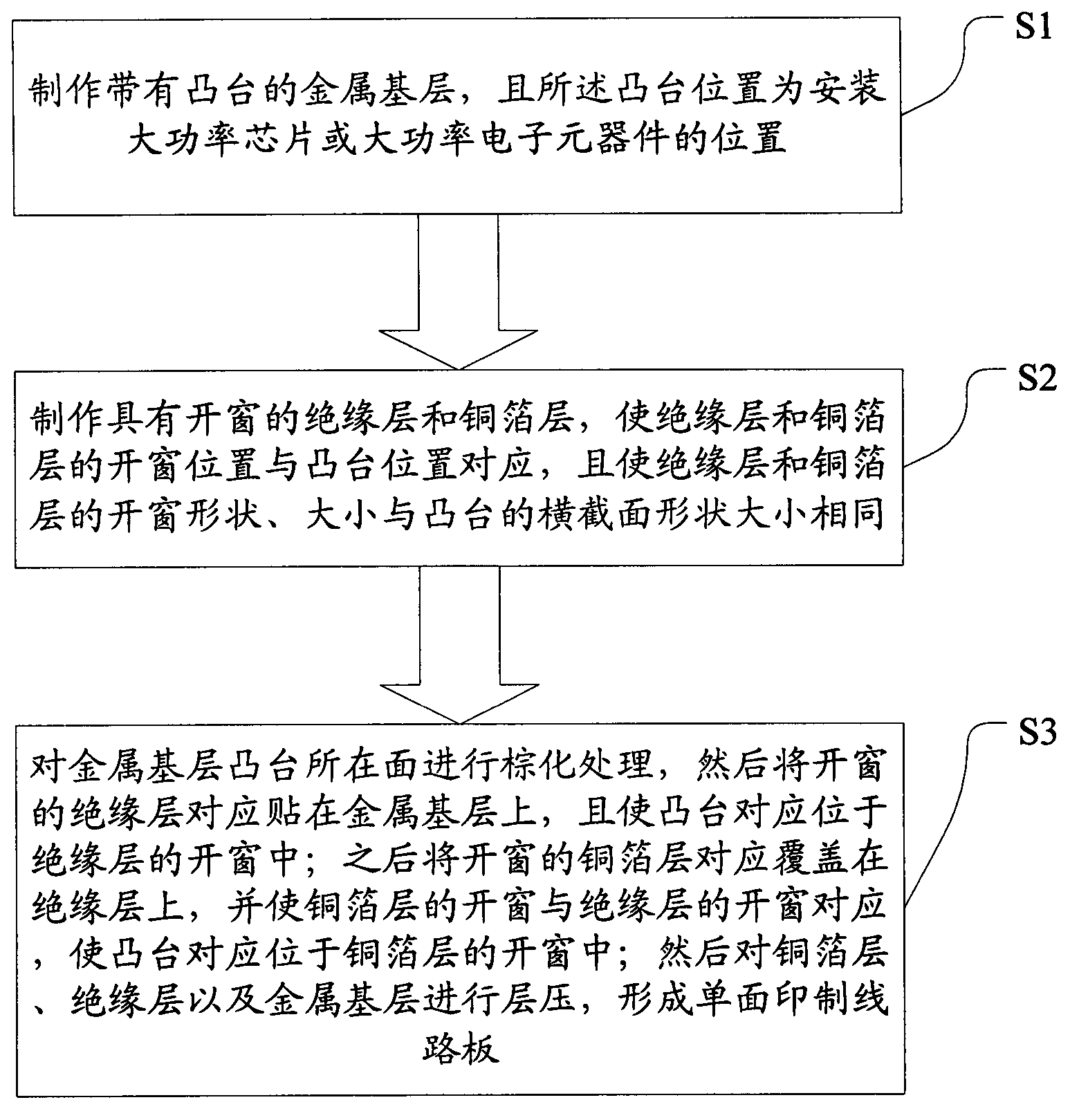

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

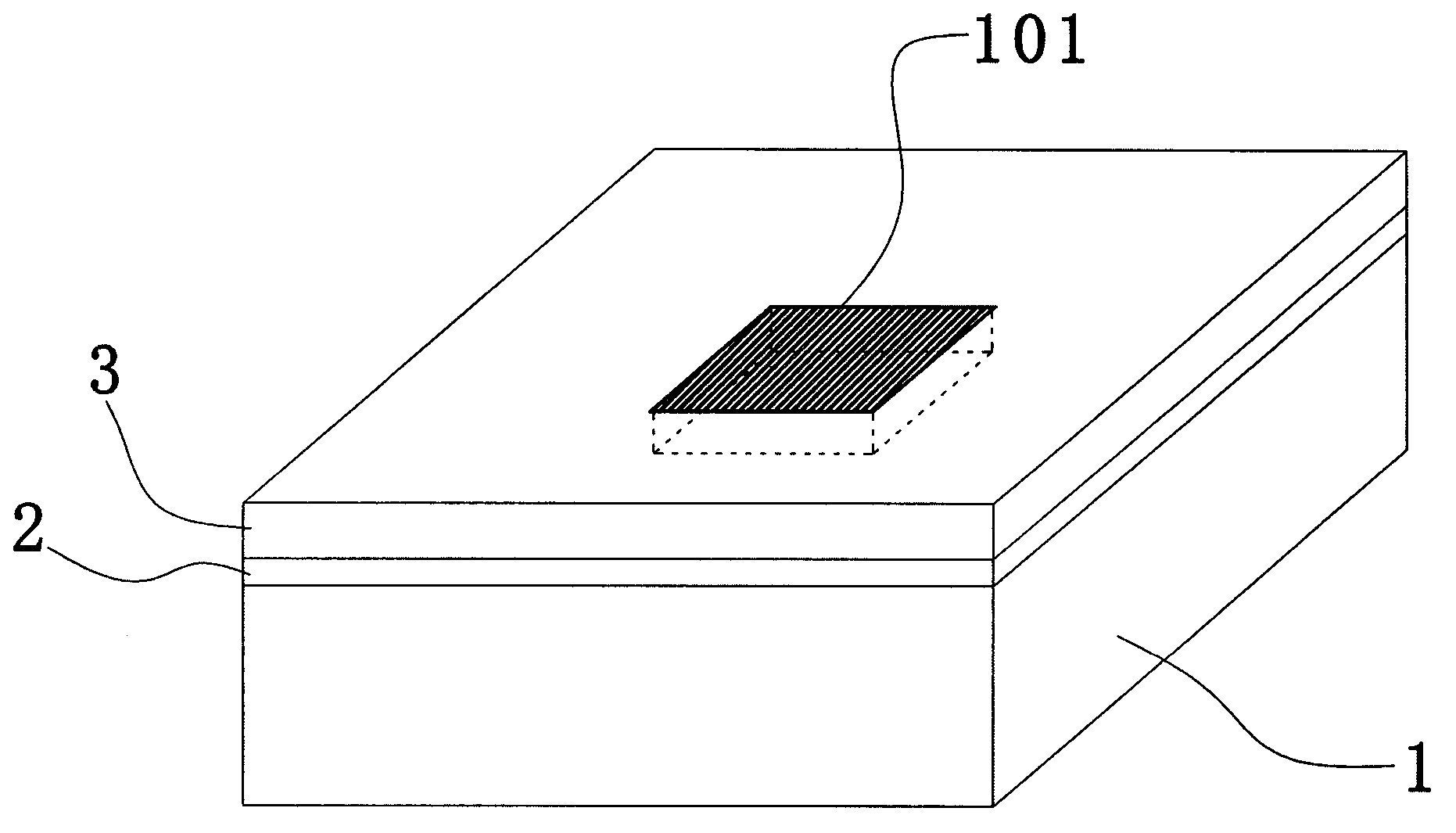

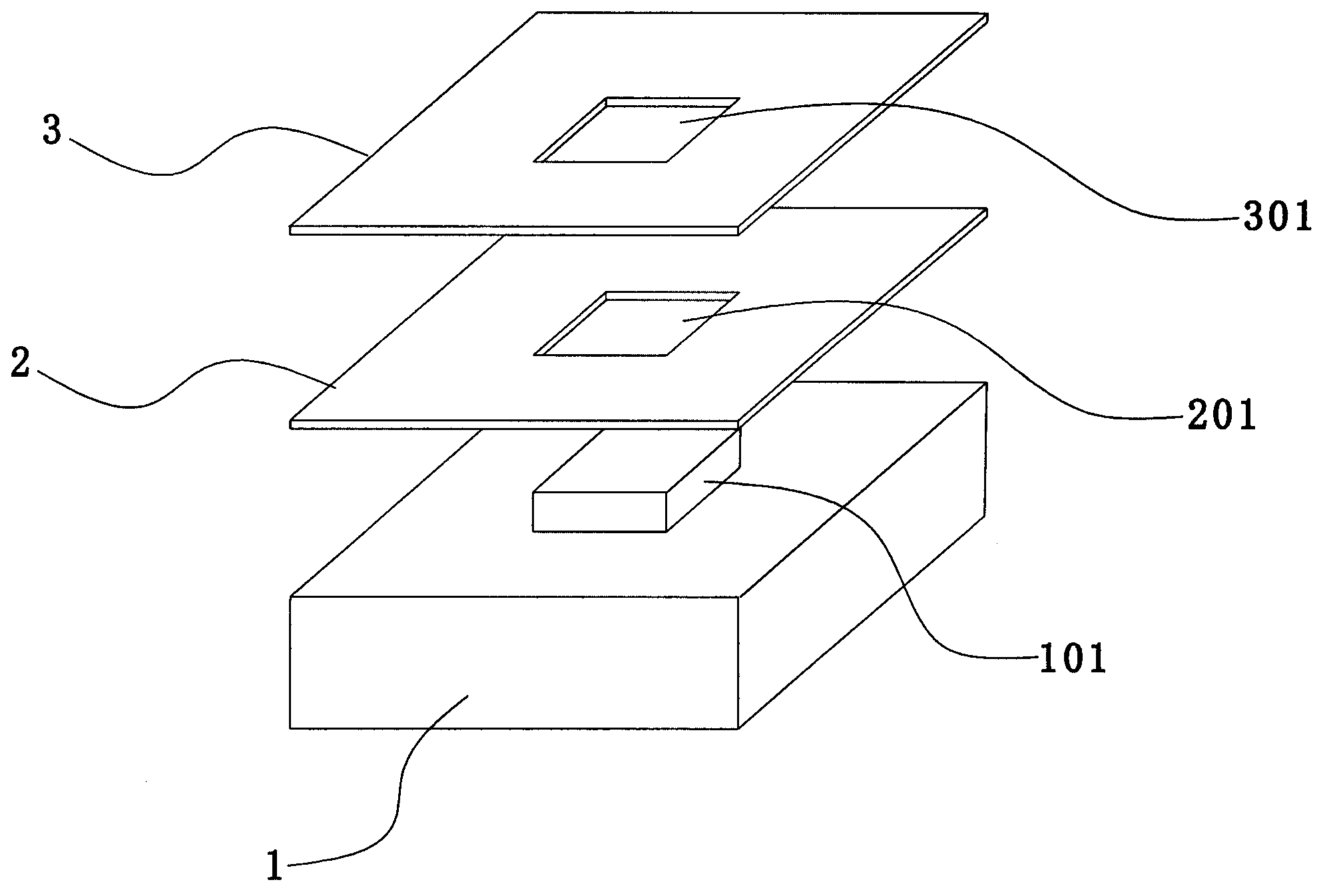

[0039] The core idea of the present invention is: by making a boss for installing high-power electronic components or high-power chips with a power greater than 150W on a copper base or an aluminum base with a thermal conductivity greater than 200W / mK, the electronic components or The non-conductor position of the chip is directly in contact with the upper surface of the metal-based boss. Since there is no heat-conducting insulating film between the electronic components or the chip and the metal-based boss, the heat dissipation efficiency is effectively improved, and the thermal conductivity of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap