Rocker arm type tension leveler

A technology of tension leveling machine and rocker arm type, which is applied in the field of metallurgical machinery, can solve the problems of unfavorable motor, influence of cast slab quality, uneconomical and other problems, and achieve the effect of convenient and easy operation, reliable and excellent performance, reasonable and economical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated into other embodiments without further recitation.

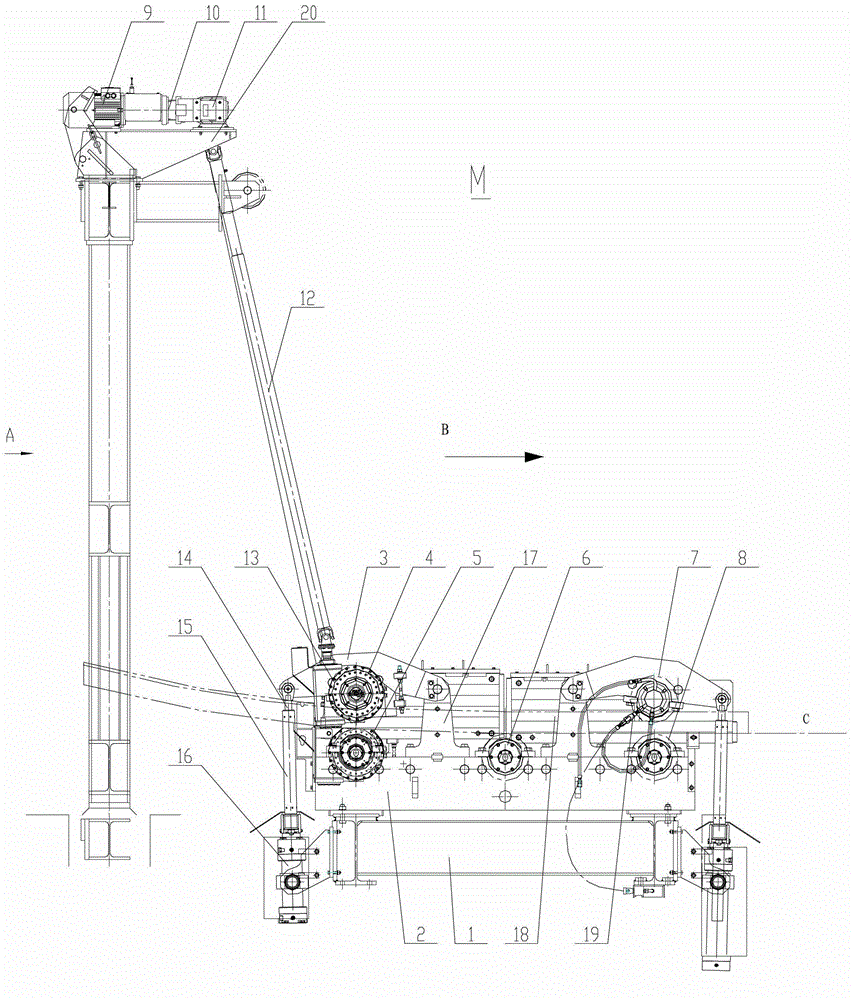

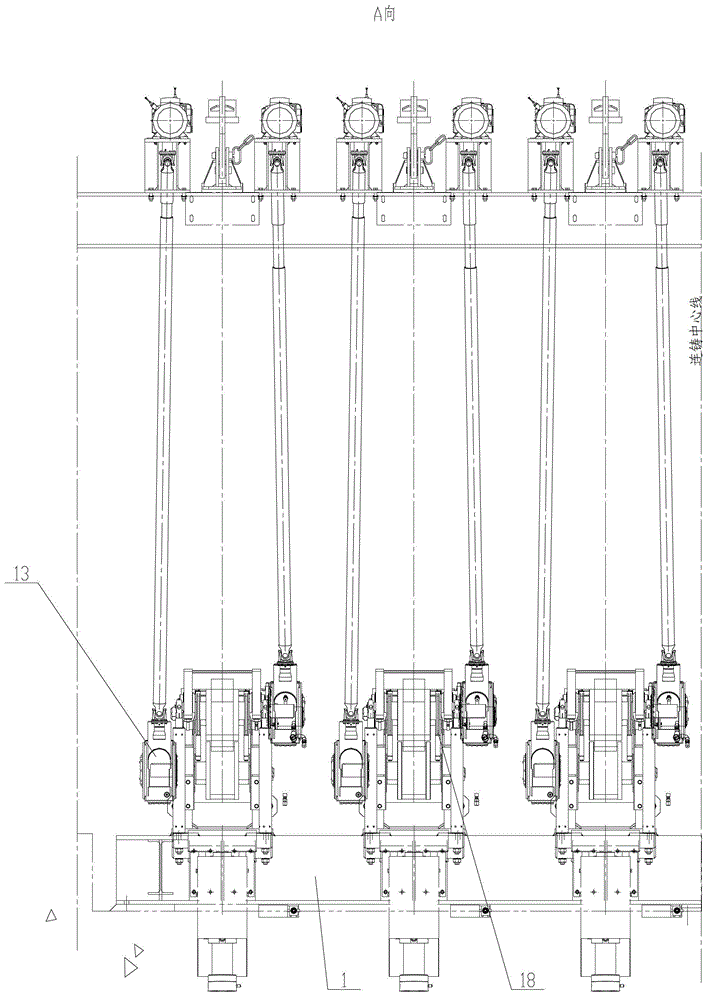

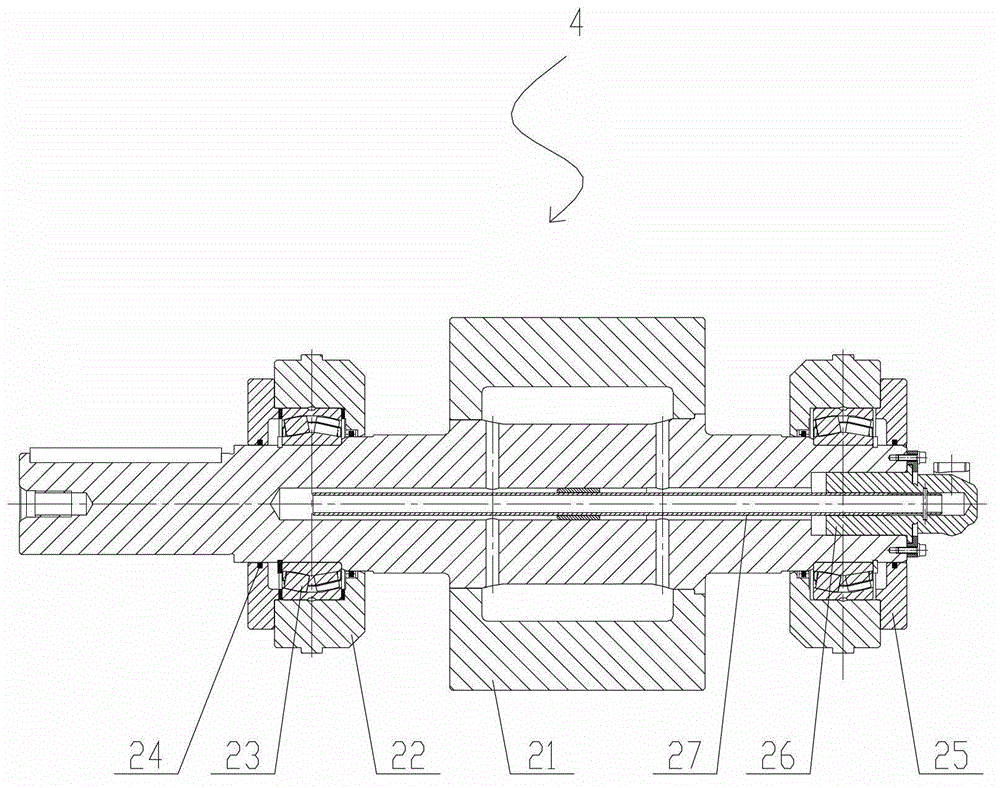

[0027] combine figure 1 with figure 2 As shown, it shows a rocker type tension leveler M according to an embodiment of the present invention. The rocker arm tension leveler M includes a power device, a transmission device connected to the power device, and a plurality of rollers. Among them, B is the casting direction, and C is the direction of the steel wire.

[0028] It is worth pointing out that the rocker arm type tension leveling machine M also includes: an overall basic frame 1, which is used to support each flow base frame 2 described below, and is used to install each flow hydraulic cylinder 16; the base frame 2, which is set without In the form of racking, it is connected abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com