Hinge mechanism

A hinge mechanism and hinge seat technology, applied in mechanically driven excavators/dredgers, etc., can solve problems such as wear and tear, and achieve the effects of reducing wear, increasing bushings, and facilitating disassembly and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

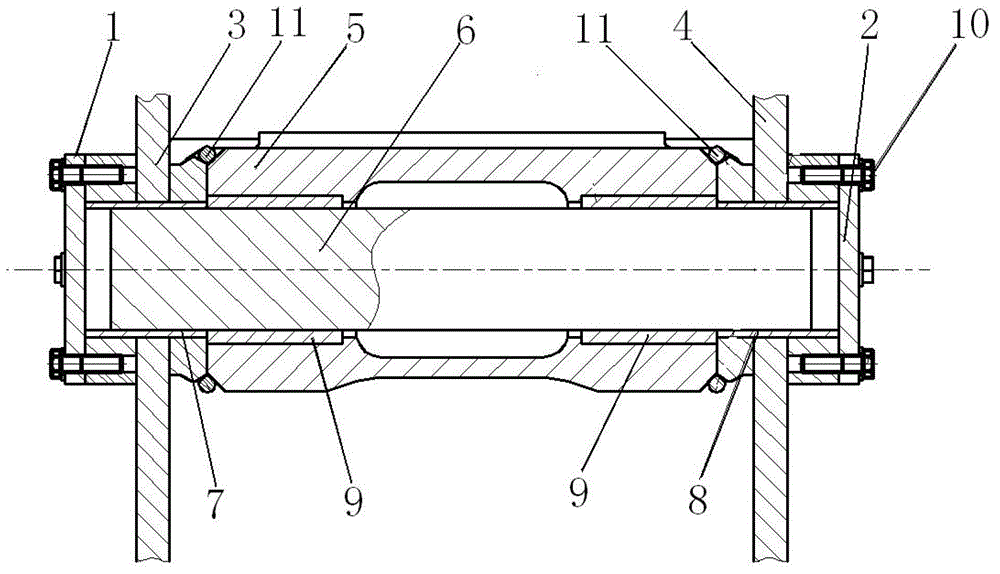

Examples

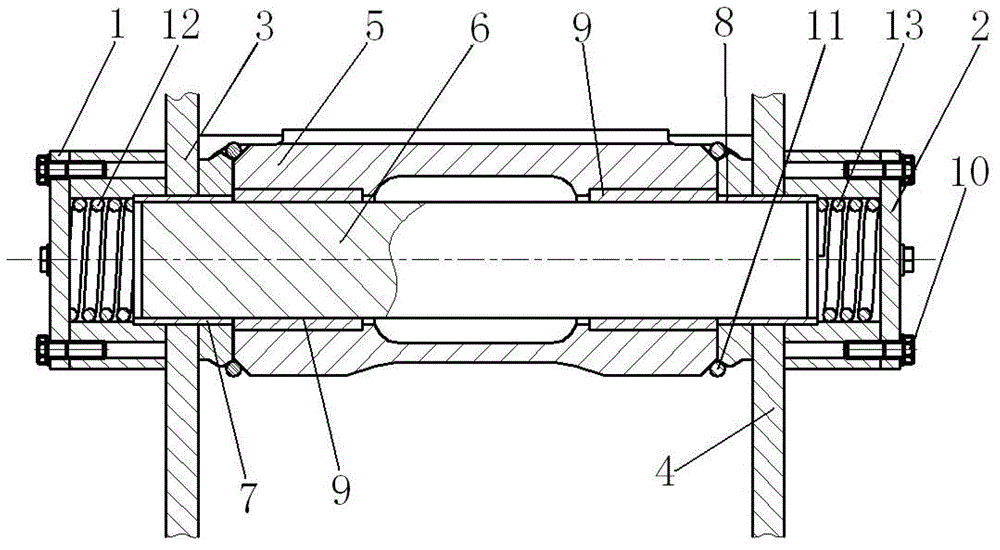

Embodiment 2

[0021] Such as figure 2 image 3 As shown, compared with the hinge mechanism in Embodiment 1, the difference is that in the hinge mechanism in this embodiment, a left return spring 12 and a right return spring 13 are arranged at both ends of the pin shaft 6, and the left return spring 12 The left end of the left return spring is contacted and connected with the left cover plate 1, the right end of the left return spring is in contact with the left end of the pin shaft 6 and the left end of the left bushing simultaneously, and the left end of the right return spring 13 is connected with the right end of the pin shaft 6 and the right end of the right bushing at the same time Contact connection, the right end is in contact with the right cover plate, that is, the left return spring 12 is limited between the left cover plate 1 and the left bushing 7, and the right return spring 13 is limited between the right cover plate 2 and the right bushing 8, Its maximum stroke is limited, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com