Glass lifting driver for vehicles and vehicle

A glass lift and driver technology, applied in manual mechanisms, power control mechanisms, door/window accessories, etc., can solve the problem that the glass lift driver cannot use manual and automatic modes at the same time, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

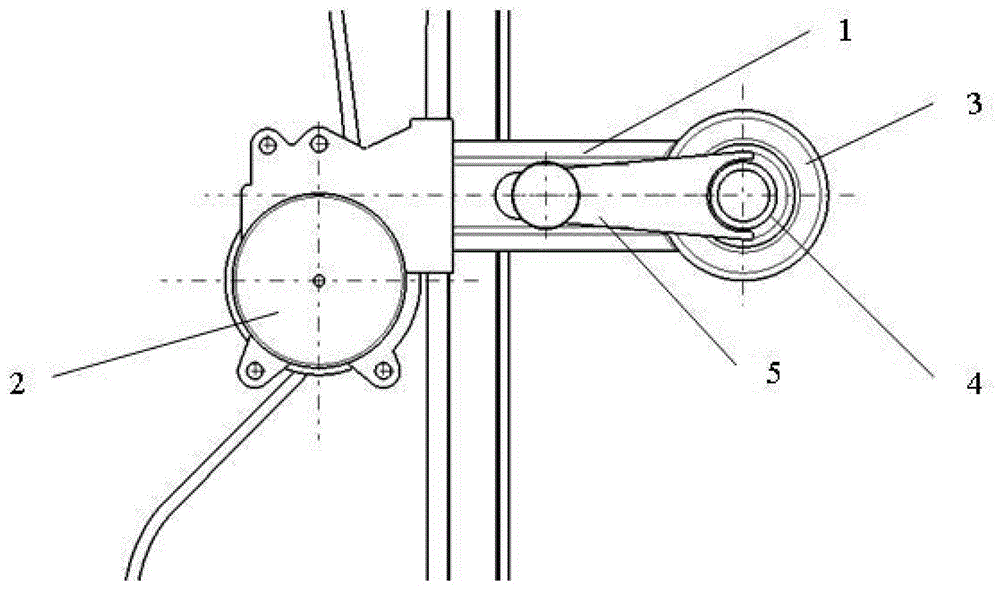

[0061] Such as Figure 9 As shown, the glass lift driver of the present invention is applied in a double guide rail sheave type glass lifter for the front door of a vehicle. The glass lifting driver is fixed on the inner panel of the car door by bolt connection, and of course, modes such as rivet connection can also be selected; the glass lifting driver is connected with the lifting glass guide rail, and the glass 41 is connected on the lifting glass guide rail.

[0062] The double-rail rope wheel type glass lifter has the characteristics of good glass lifting balance and small friction to the sealing strip, so the operating force of the manual rocker mechanism 5 is small in the manual driving state. The double guide rail rope wheel type glass lifter can arrange the glass lift driver at any position, so the manual rocker mechanism 5 can be arranged at any position of the door trim panel, which is convenient for the styling design of the vehicle interior. The radian of the gla...

Embodiment 2

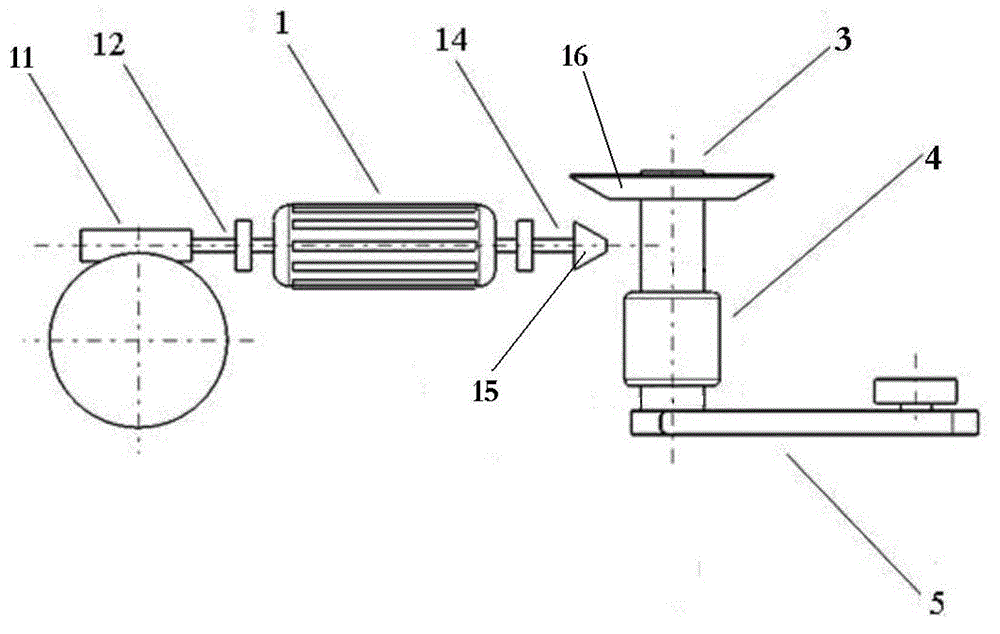

[0064] Such as Figure 10 As shown, the window lift driver of the present invention is applied in a single guide rail rope pulley glass lifter for the rear door of a vehicle. The glass lifting driver is fixed on the inner panel of the car door by bolt connection, and of course, modes such as rivet connection can also be selected; the glass lifting driver is connected with the guide rail of the lifting glass 41, and the glass 41 is connected on the lifting glass guide rail.

[0065] The single guide rail rope wheel type glass lifter can arrange the glass upgrade driver at any position, so the manual rocker mechanism 5 can be arranged at any position of the door trim panel, which is convenient for the styling design of the vehicle interior. The radian of the glass lift guide groove of the single guide rail rope wheel type glass lifter can be freely designed, which is suitable for the case where the glass curved surface has a large radian.

Embodiment 3

[0067] Such as Figure 11 As shown, the window lift drive according to the invention is used in a cross-arm window lifter for a rear door of a vehicle. The glass lifting driver is fixed on the inner panel of the car door by means of bolt connection, of course, other methods such as rivet connection can also be selected;

[0068] The cross-arm type glass lifter can be equipped with a balance spring 42, which can balance the operating force difference of the manual rocker mechanism 5 when the glass 41 rises and falls. The force is less. The cross-arm glass lifter can adapt to the curved surface movement of the glass through the elastic deformation of the cross-arm structure. Therefore, in the case of a small curvature of the glass surface, the generalization of the lifting mechanism can be realized, and the cost and risk of vehicle development can be reduced; the cross-arm The type glass regulator can adapt to harsh working conditions, such as trucks, cross-type passenger cars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com