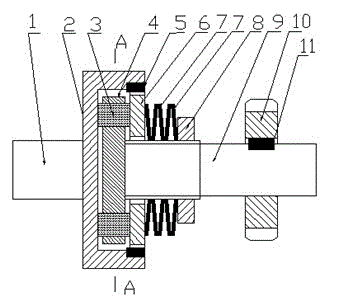

Safety clutch for drilling machine

A technology for safety clutches and drilling rigs, applied in clutches, automatic clutches, mechanical equipment, etc., can solve problems such as high failure rate, unreliable work, broken drill bits, etc., and achieve low failure rate, high failure rate and reliable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

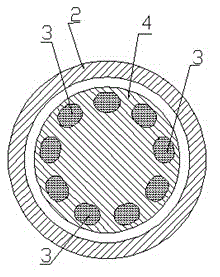

[0009] An output shaft (1) is installed and fixed at the center outside the bottom end of the coupling sleeve (2), and an inner ring gear (5) is installed and fixed at the right port of the coupling sleeve (2), through which the friction disc (6) The outer ring gear on the outer circle fits with the inner teeth of the inner ring gear (5) and is installed in the middle of the inner ring gear (5), and a drive is set between the friction disc (6) and the coupling sleeve (2). Disc (4), friction block (3) is arranged in the through hole evenly distributed along the circumference of both sides of the drive disc (4), the friction block (3) is made of copper wire asbestos material, the left end of the driving shaft (9) passes through The middle hole of the friction disc (6) is connected and fixed to the center of the drive disc (4), and an adjusting nut (10) is installed on the driving shaft (9) close to the position of the friction disc (6). On the driving shaft (9) between the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com