Paraffin wax transmitting pipeline

A technology for conveying pipelines and paraffin, which is applied in pipeline protection, pipeline heating/cooling, and pipeline protection through heat insulation, etc. It can solve problems such as poor compatibility and sticky products, achieve uniform heating and ensure normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

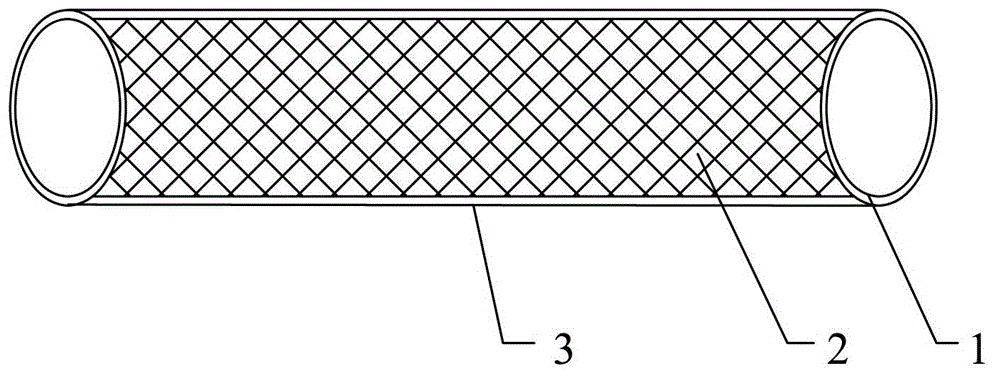

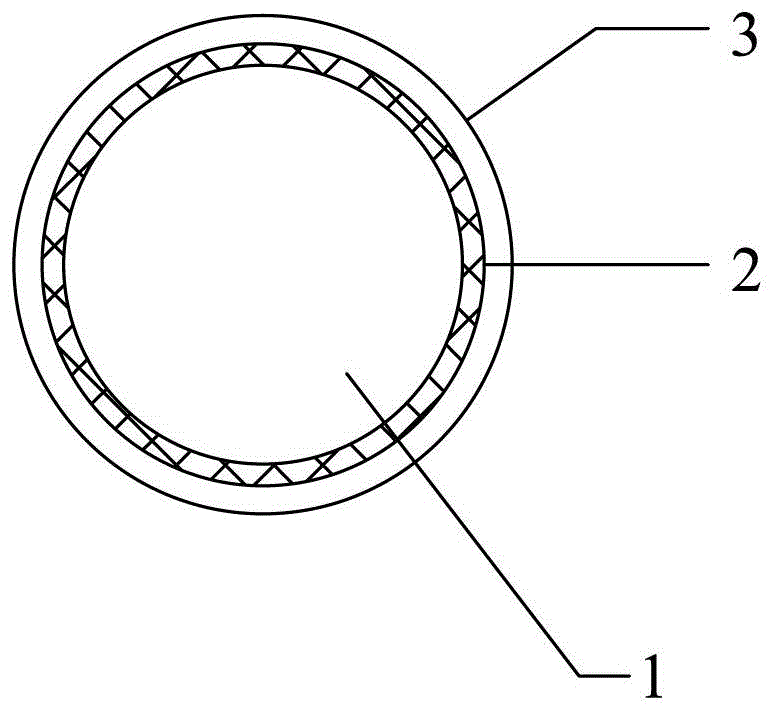

[0014] The present invention provides a paraffin transport pipeline, and the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] like figure 1 , figure 2 As shown, a paraffin delivery pipeline is characterized in that: a layer of electric heating wire heating layer 2 for preventing the solidification of paraffin is provided on the outside of the pipeline 1 supplying liquid paraffin flow, and an electric heating wire heating layer 2 is also provided on the outside of the electric heating wire heating layer 2 There is one layer of insulation layer 3 used to prevent the heat loss of the pipeline, and the insulation layer 3 is made of heat-sensitive material that can display different colors as the temperature changes.

[0016] The heat-sensitive material used to make the insulation layer 3 is heat-sensitive color-changing fiber.

[0017] The electric heating wire heating layer 2 has a grid-like arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com