Anti-icing box-shaped rail beam

A track beam and anti-icing technology, which is applied in the direction of track, road, heating element shape, etc., can solve the problems of inoperability, vehicle slipping and stalling, small heating area of track beam, etc., to prevent rainwater from freezing, good overall performance, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

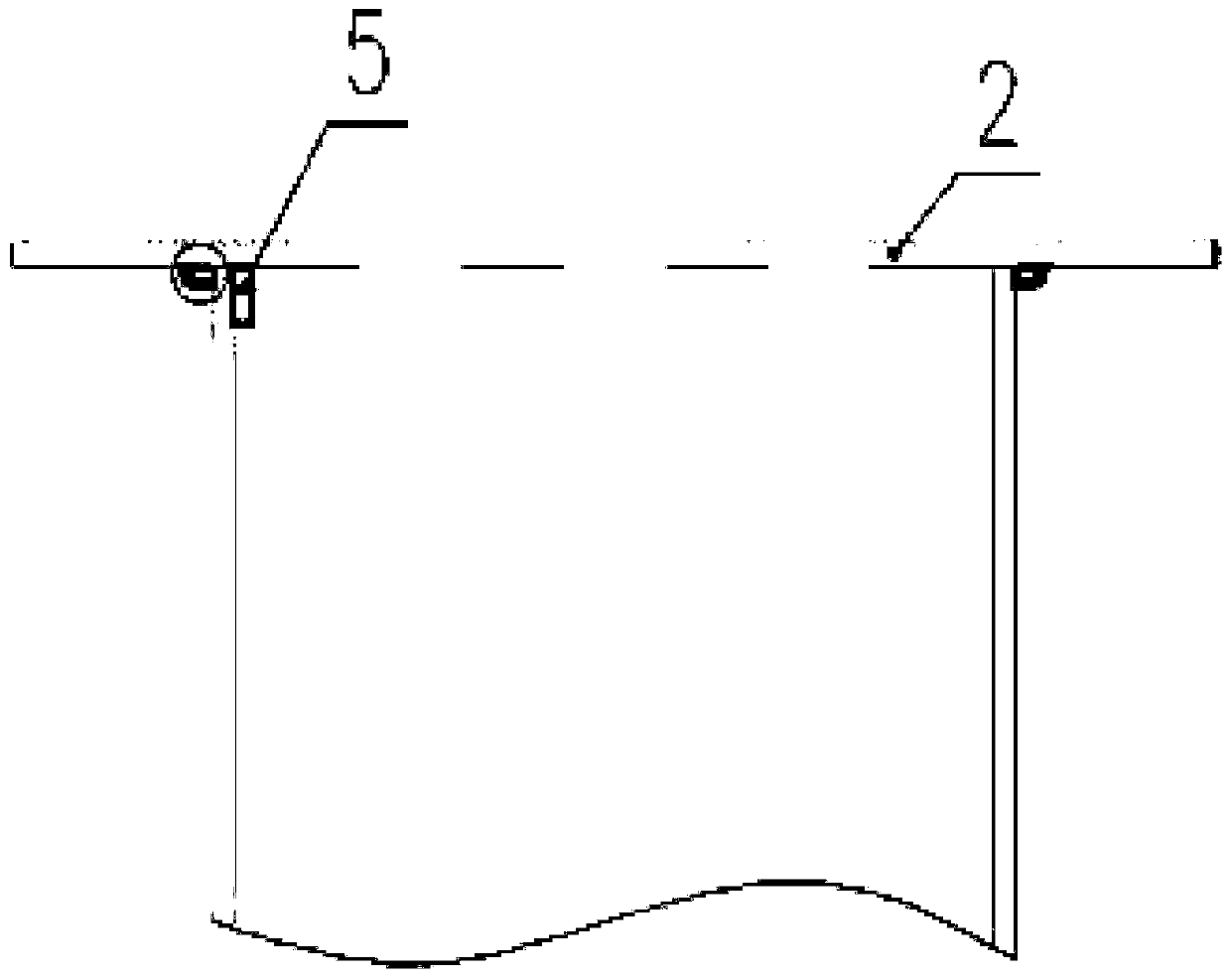

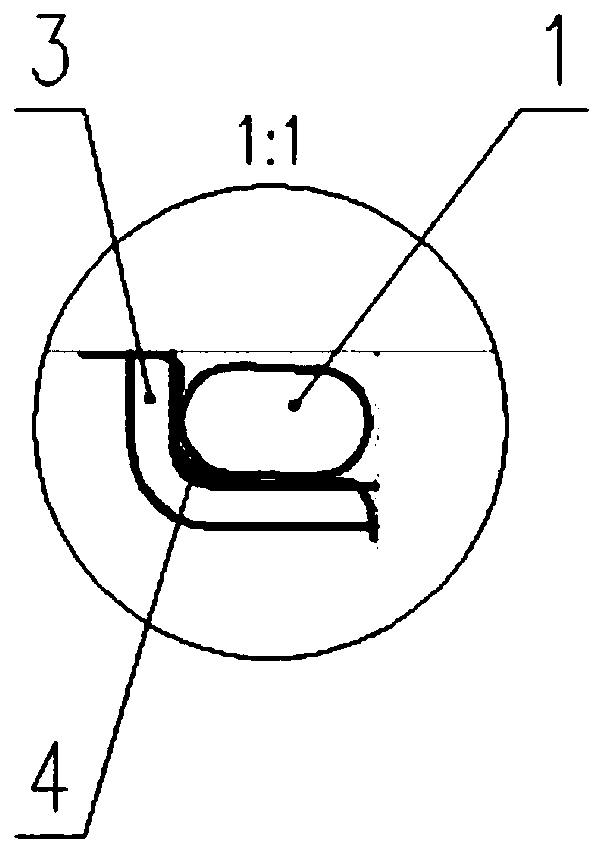

[0020] Referring to Fig. 1(a) and Fig. 1(b), the present invention proposes an anti-icing box-shaped track beam, comprising a T-shaped track beam beam and a track beam vertical beam; the track beam beam and the track beam vertical beam The heating cable 1 is installed at the junction of the beams. The heating cable 1 is laid along the beam of the track beam 2. After being energized, it can generate heat by itself and indirectly heat the track through thermal radiation. After the heating cable is energized, the temperature can reach 70°C, and the heat of the heating cable will quickly The heating cable 1 is fixed to the track beam 2 through the fixed bracket 3; the fixed bracket 3 is L-shaped, and the two ends of the fixed bracket 3 are respectively It is connected to the track beam beam and the track beam vertical beam; the fixed bracket is arranged at an interval of 200mm; the heat insulation layer 4 is arranged on the outside of the heating cable 2, and the heat insulation la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com