Refrigerator

A technology for refrigerators and outer boxes, applied in the field of refrigerators, can solve the problems of increasing the amount of vacuum insulation materials, increasing the amount of heat intrusion, and limiting the volume of vacuum insulation materials, and achieving the effect of reducing intrusion heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

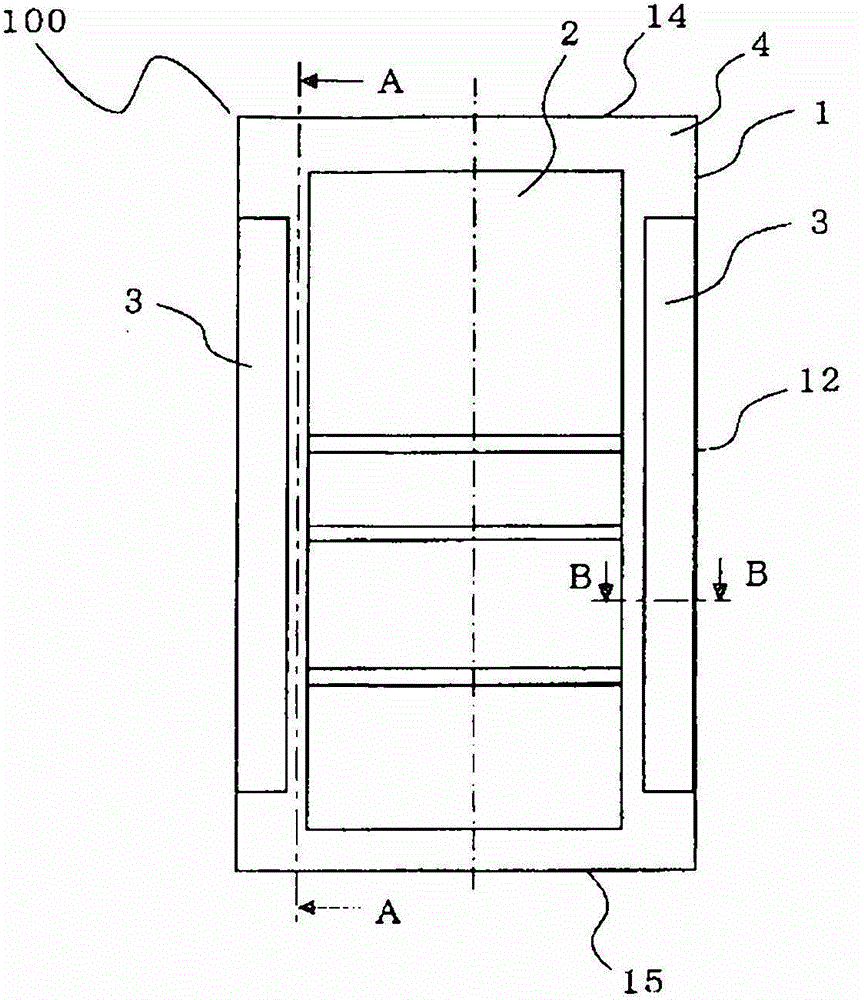

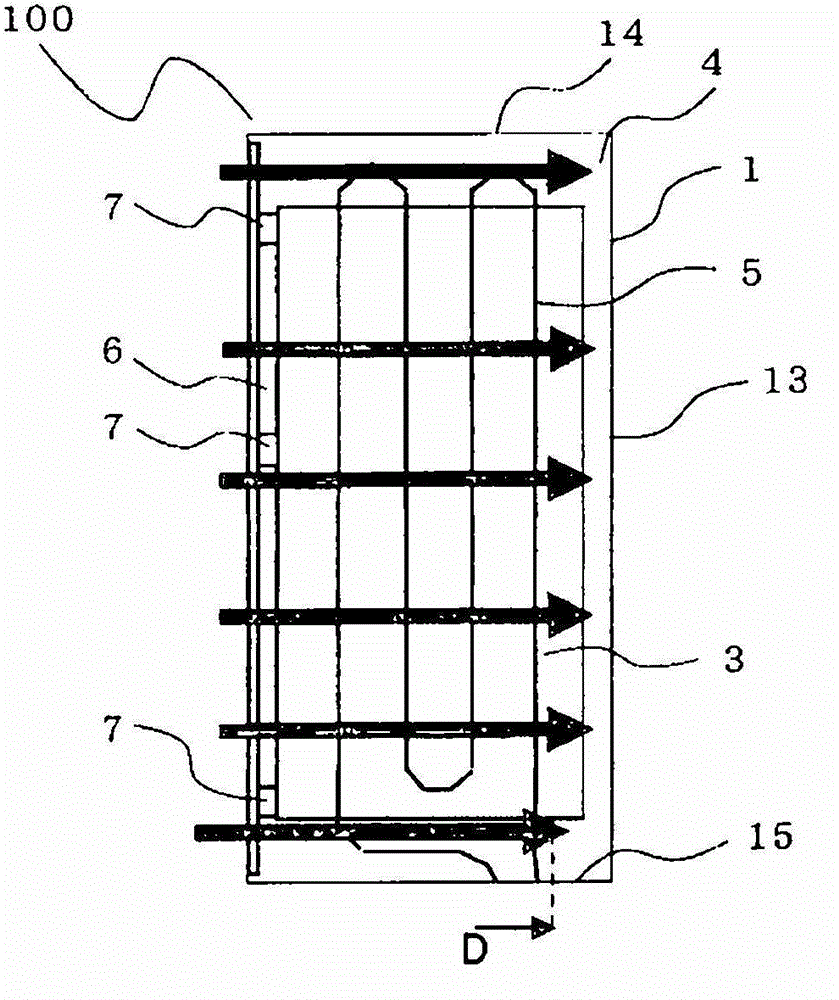

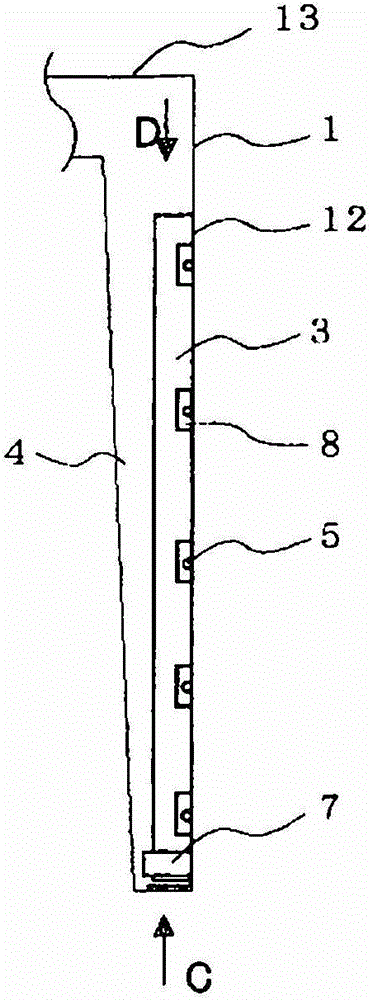

[0031] figure 1 It shows a front cross-sectional view of refrigerator 100 in Embodiment 1 of the present invention. figure 2 express figure 1 A-A sectional view of . image 3 express figure 1 BB sectional view of . Figure 4 It is a schematic explanatory drawing showing the positional relationship of the vacuum heat insulating material 3, the cushioning material 7, and each flange part in Embodiment 1 of this invention. and, Figure 4 for zoomed in image 3 A diagram of the front of the .

[0032] Next, use Figure 1 to Figure 4 The configuration of refrigerator 100 will be described.

[0033] figure 1 The refrigerator 100 is configured by fitting an outer box 1 made of metal such as iron and an inner box 2 made of synthetic resin such as ABS. The side surface 12 of the outer box 1 is provided on the side of the refrigerator 100 , the top surface 14 of the outer box 1 is provided on the upper surface of the refrigerator 100 , and the bottom surface 15 of the outer...

Embodiment approach 2

[0057] Next, use Figure 8 Embodiment 2 of the present invention will be described. In addition, in Embodiment 2, items that are not particularly described are the same as in Embodiment 1, and the same functions and configurations will be described using the same symbols.

[0058] Figure 8 It is a schematic explanatory drawing which shows the positional relationship of the vacuum heat insulating material 3 and each flange part in Embodiment 2 of this invention.

[0059] After forming the fitting recessed part 18a, the back flange 18 is bent 180 degrees, and is extended toward the outer case 1 direction. The vicinity of the bent portion of the back flange 18 is in close contact with the vacuum insulation material 3 . The front end portion 18b of the extended portion of the rear flange 18 toward the outer box 1 is located in front of the refrigerator 100 in the front-rear direction of the refrigerator 100 compared to the position in contact with the vacuum insulation materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com