Architecture locating device for bogie parameter test bench

A technology of parameter testing and positioning device, applied in the direction of railway vehicle testing, etc., can solve the problem of not being able to locate in three directions at the same time, and achieve the effect of convenient and reliable operation and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the drawings:

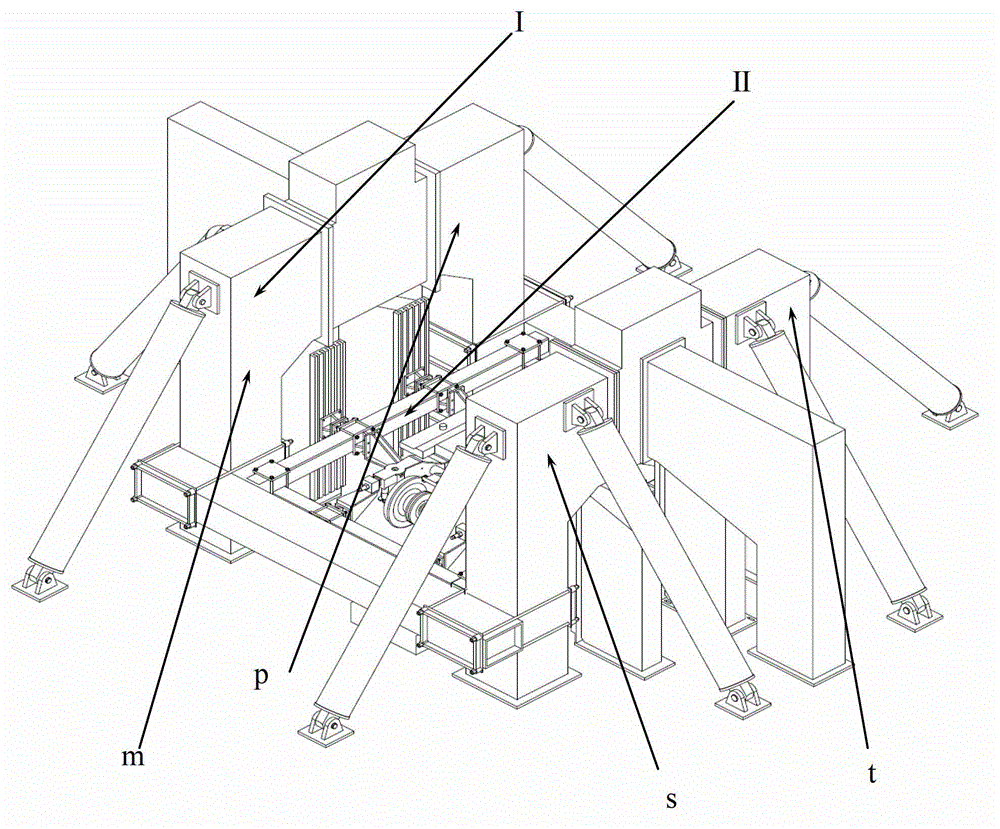

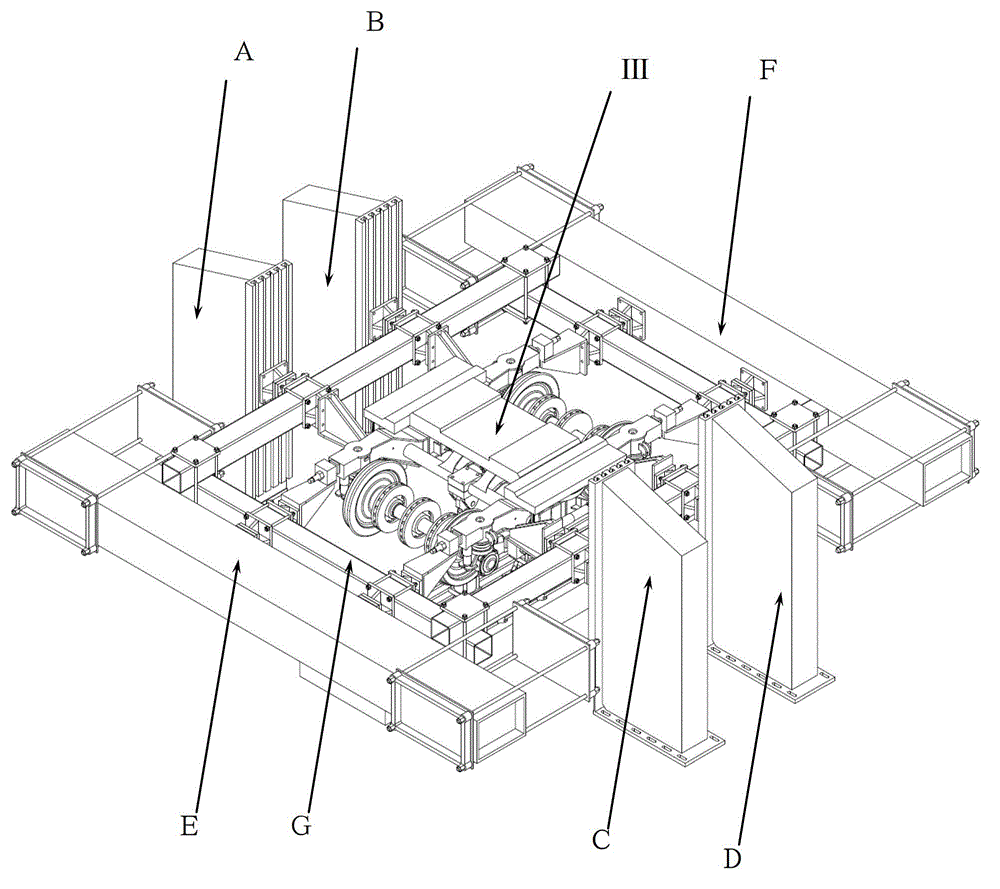

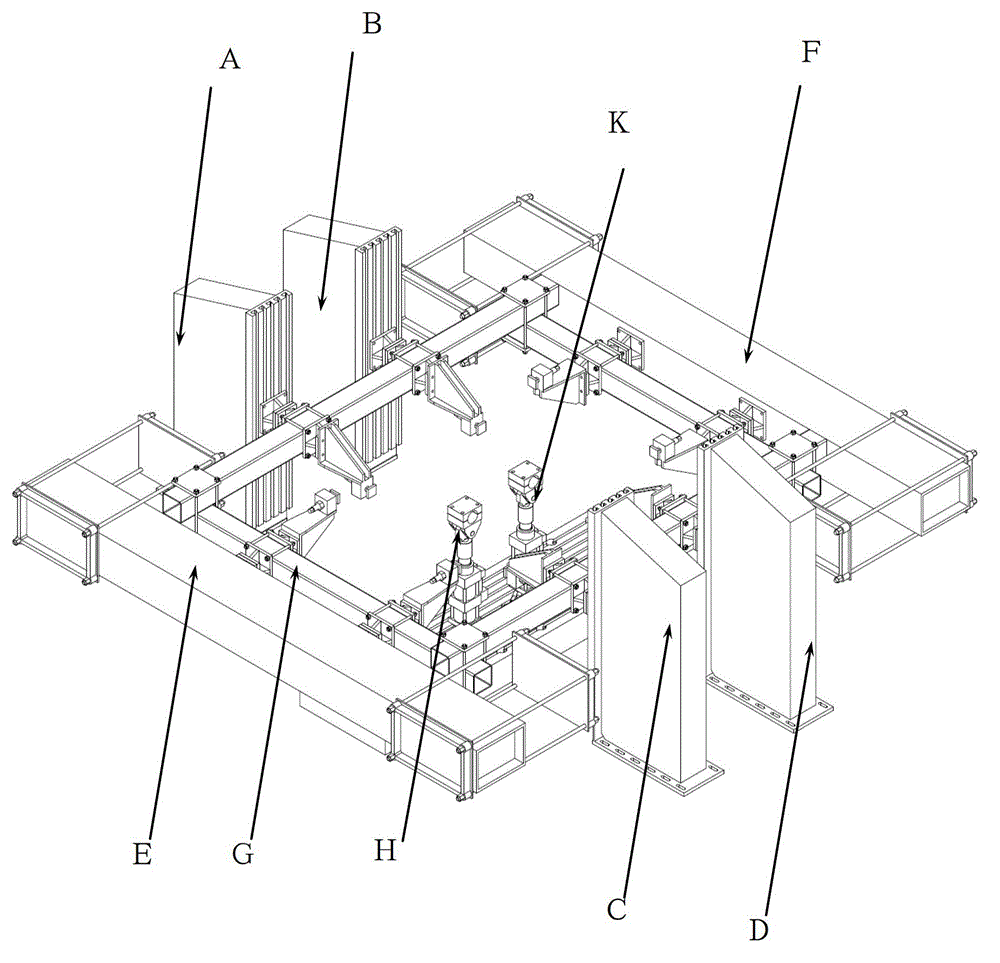

[0037] Refer to Figure 1 to Figure 3 , The frame positioning device II of the bogie parameter test bench of the present invention is a frame structure device, which relies on the gantry-type mechanical structure of the bogie parameter test bench I to realize its own positioning and installation, which mainly includes the No. 1 thrust beam assembly Cheng E and No. 2 thrust beam assembly F, No. 1 transverse reaction support A, No. 2 transverse reaction support B, No. 3 transverse reaction support C, No. 4 transverse reaction support D, longitudinal and transverse directions Constraint frame G, No. 1 vertical positioning mechanism assembly H, and No. 2 vertical positioning mechanism assembly K. Among them, No. 1 thrust beam assembly E and No. 2 thrust beam assembly F provide vertical and horizontal restraint frame G with reaction support in the longitudinal direction. In the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com