Tool for motor rotor into shaft

A technology of motor rotor and tooling, applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of cast aluminum rotor radial runout exceeding the error, the force deformation of the cast aluminum shaft, and the unbalanced rotation of the cast aluminum rotor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

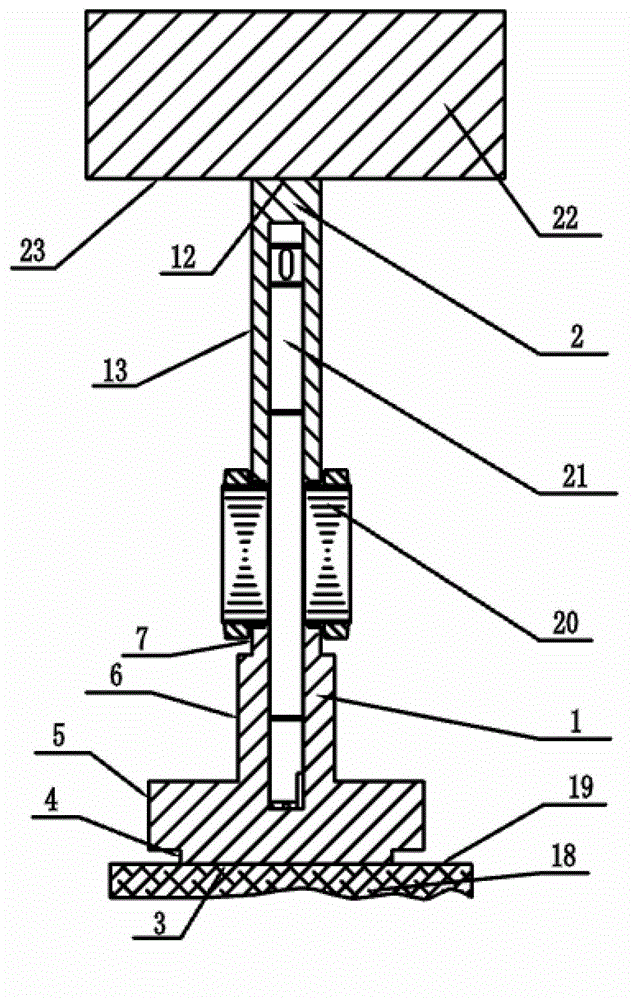

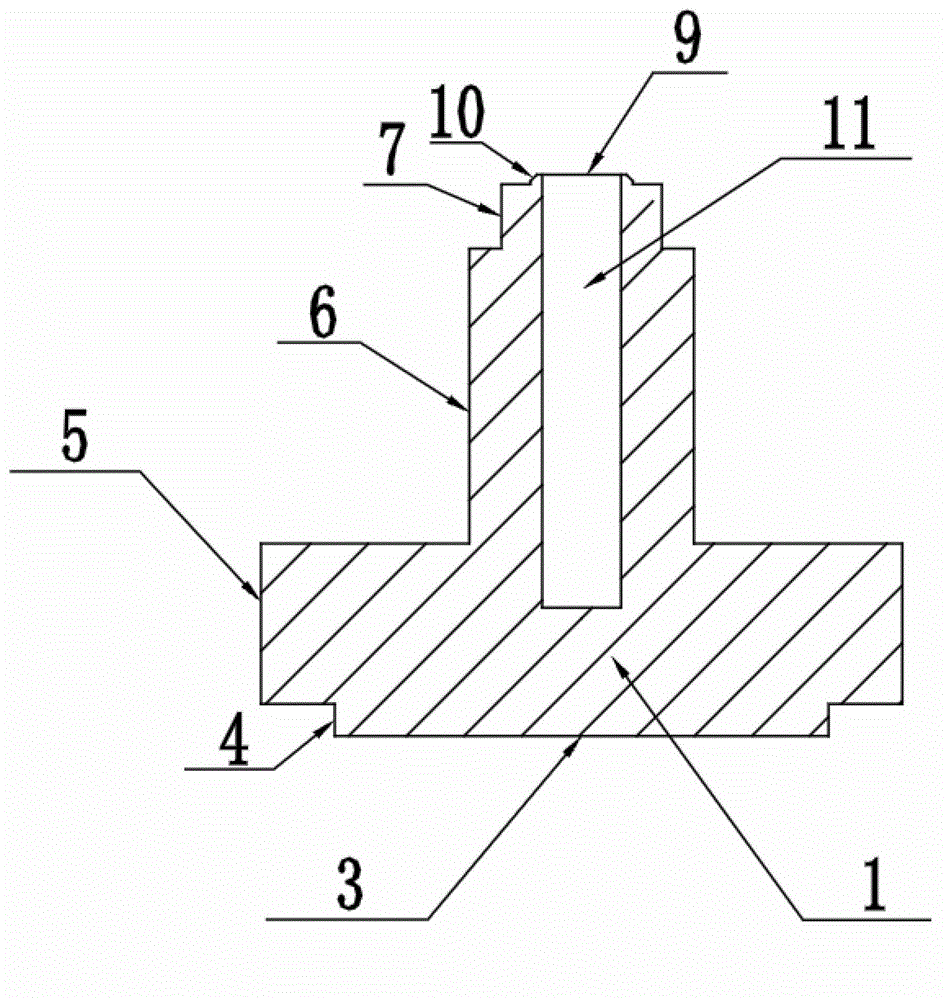

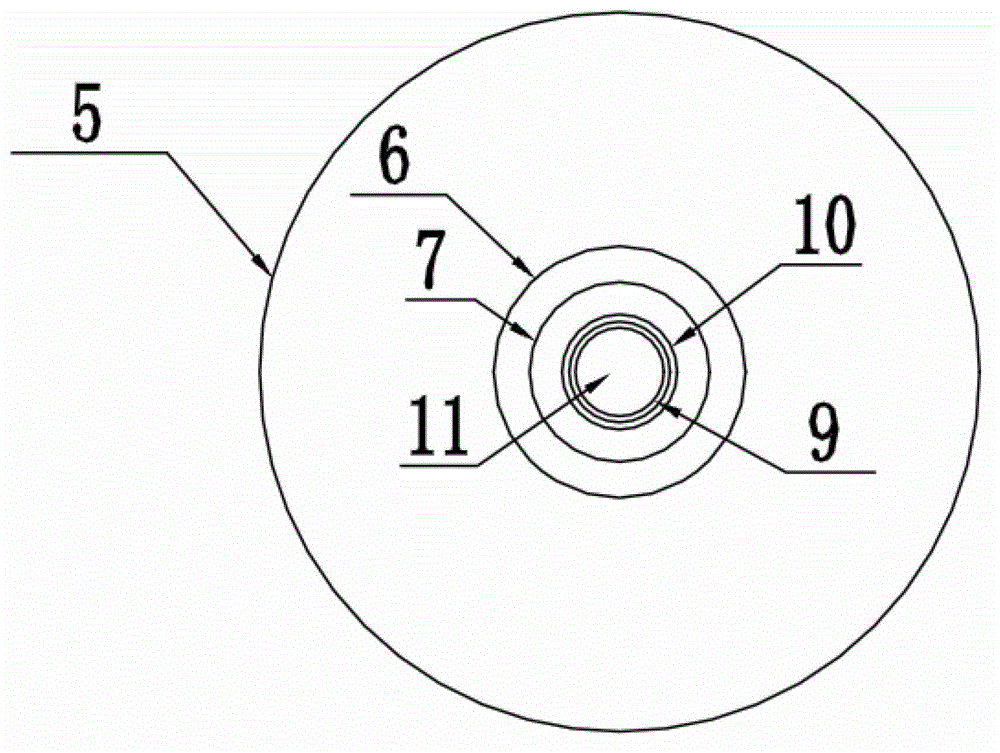

[0024] First, place the lower chassis 1 of the tooling on the flat upper surface III19 of the workbench 18, insert one end of the mandrel 21 into the central cylindrical hole I11 of the lower chassis 1 of the tooling, and ensure that the mandrel 21 and the central cylindrical hole I 11 The end surface of the connected end is in contact with the bottom end surface of the central cylindrical hole I 11, and penetrates the cast aluminum rotor 20 from the other end of the mandrel 21, so that the cast aluminum rotor 20 is connected with the mandrel 21 through the center hole, and under the action of its own gravity, the cast aluminum rotor 20 The lower end surface of the aluminum rotor 20 is kept in contact with the flat upper surface I9 of the boss I10, and the tooling upper sleeve 2 is inserted into the other end of the mandrel 21 through the central cylindrical hole II14. Under the action of its own gravity, the boss II15 The flat lower end surface II 16 is kept in contact with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com