Washing machine and method for operation of a washing machine

A laundry processing machine and laundry processing technology, applied to other washing machines, household clothes dryers, applications, etc., can solve problems such as duplication, and achieve the effect of accurate and energy-saving clothing processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

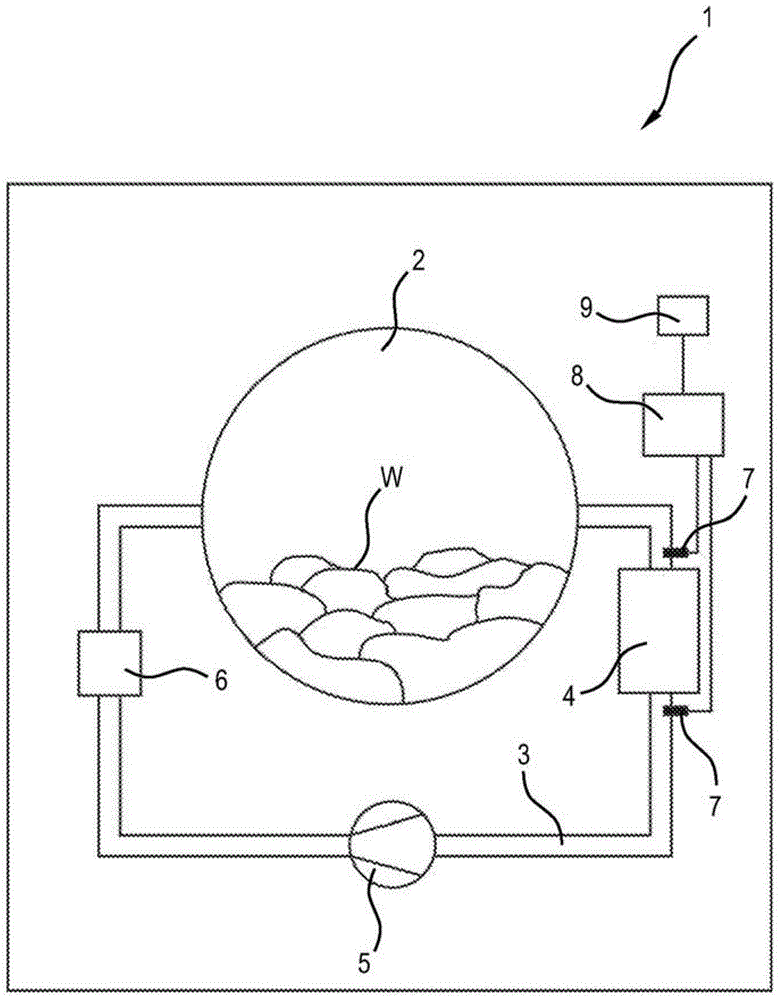

[0035] figure 1 A simplified diagram of a laundry dryer in the form of an air-circulating laundry dryer 1 is shown. The laundry dryer 1 has a laundry treatment chamber 2 (for example, a rotatable laundry drum) for receiving laundry W to be dried. The laundry treatment chamber 2 is part of a peripheral treatment air passage 3 . Said process air channel 3 also comprises at least one condenser 4 , a fan 5 and a heating element 6 . Using a fan 5, treatment air is blown into the laundry treatment chamber 2, which treatment air has been heated by the heating element 6 before being blown into the laundry treatment chamber. The hot dry air flowing into the laundry treatment chamber 2 heats the laundry W, so that moisture is discharged into the air. The relatively humid treatment air is now brought from the laundry treatment chamber 2 to the condenser 4 where it is cooled and condensed. The now cooler and again drier treatment air is conveyed again by the fan 5 via the heating elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com