Vamp shaping and sole synthesizing method

A synthesis method and surface forming technology, which is applied in the direction of bonding shoe parts, clothing, shoe lasts, etc., can solve the problems of technological research and development and technological innovation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, will figure 2 In each hinge body 21 and figure 1 The edges are aligned, and after a plurality of positioning nails 20 are forked into the corresponding positioning holes 10, the figure 1 Dedicated midsole upper surface with Figure 4 The midsole support body 40 is docked, and the Figure 5 The main heel shaping body is installed in the rear part of the sole support body 40, and completes the auxiliary tool for forming the inner cavity of the shoe.

Description of drawings

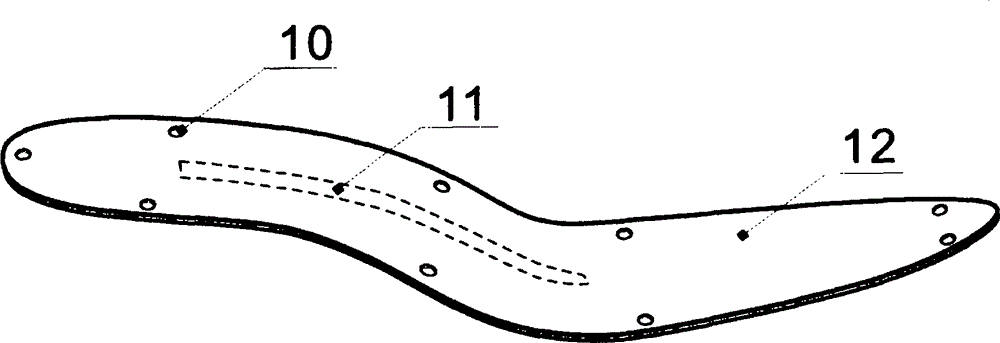

[0020] figure 1 It is a schematic diagram of the special midsole of the present invention;

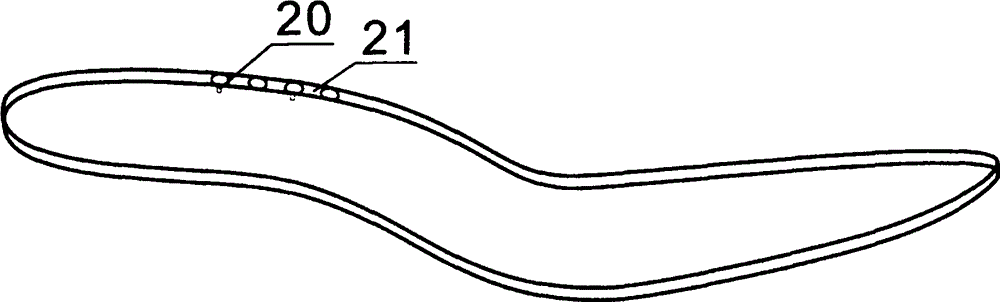

[0021] figure 2 It is a schematic diagram of the hinged side stretching device of the present invention;

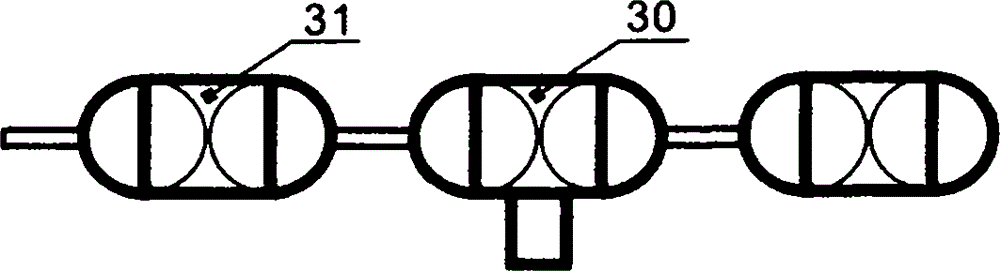

[0022] image 3 is a schematic diagram of the hinge body of the present invention;

[0023] Figure 4 is a schematic diagram of the upper support body of the present invention;

[0024] Figure 5 It is a schemati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com