Locking structure of needle barrel and core rod of safety syringe with retractable needle point

A technology for safe syringes and syringes, applied in the direction of syringes, hypodermic injection devices, infusion sets, etc., can solve the problems of reducing the assembly efficiency of the core rod and the syringe, increasing the manufacturing cost, and complicating the assembly, so as to achieve a fast and convenient assembly process , Reduce accessories, simplify the effect of assembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

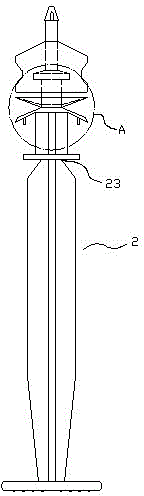

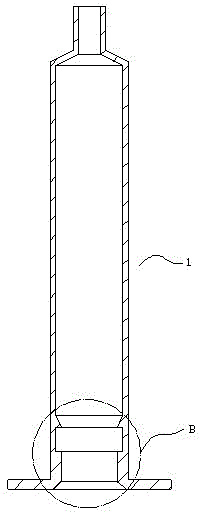

[0028] like Figure 1-8 As shown, a locking structure of a syringe and plunger of a safety syringe with a retractable needle tip, including a syringe 1 and a plunger 2 .

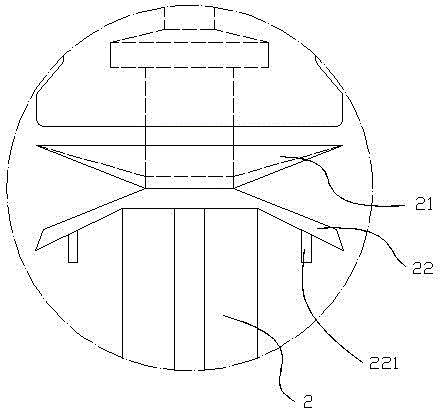

[0029] The inner hole of the syringe 1 is provided with upper and lower convex rings 11 and 12 at the tail. Wherein the upper side 111 of the upper convex ring 11 is an inclined surface arranged obliquely inwardly from top to bottom, and the lower side 112 of the upper convex ring 11 is vertically arranged with the inner hole wall of the syringe. The upper side 121 of the lower protruding ring 12 is arranged perpendicular to the inner hole wall of the syringe, and the lower side 122 of the lower protruding ring 12 is a slope arranged obliquely from top to bottom. An engaging groove 13 is formed between the upper and lower protruding rings 11 , 12 .

[0030] The body of the core rod 2 is provided with upper and lower flanges 21, 22 whose outer diameter is larger than the inner diameter of the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com