Modular cloth bag deduster

A bag filter and modular technology, applied in the field of mechanical manufacturing and processing, can solve the problems of difficult shipment, high transportation cost, inconvenient transportation, etc., and achieve the effects of facilitating disassembly and transportation, simplifying the production process, and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

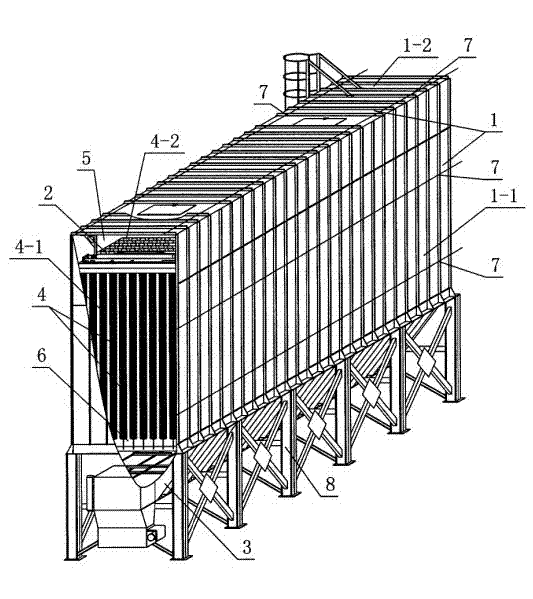

[0017] As shown in the drawings, a modular bag filter includes a housing 1 , a flower plate 2 , a collecting device 3 and a filtering device 4 , and also includes a frame 8 . The flower plate 2 separates the housing 1 into an upper clean room 5 and a lower filter room 6 , and the collecting device 3 is arranged at the lower part of the filter room 6 . The filter device 4 includes a filter bag 4-1 and a cage frame 4-2, the filter bag 4-1 is set outside the cage frame 4-2, and the cage frame 4-2 is connected to the flower plate 2. The housing 1 is a modular structure, and the housing 1 is composed of several side modules 1-1 and several upper modules 1-2. Adjacent side modules 1-1 are fixedly connected together through fixed connectors 7, and adjacent upper modules 1-2 are fixedly connected together through fixed connectors 7. Between the side modules 1-1 and the upper module 1-2 The room is fixedly connected together by a fixed connector 7.

[0018] The fixed connectors 7 are...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap