Preparation method of gear for corrosion-resistant oil transfer pump

An oil pump and corrosion-resistant technology, applied in the field of oil pumps, can solve problems such as not suitable for the use of oil pumps, and achieve the effects of low noise, high bending strength, and large overlap coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

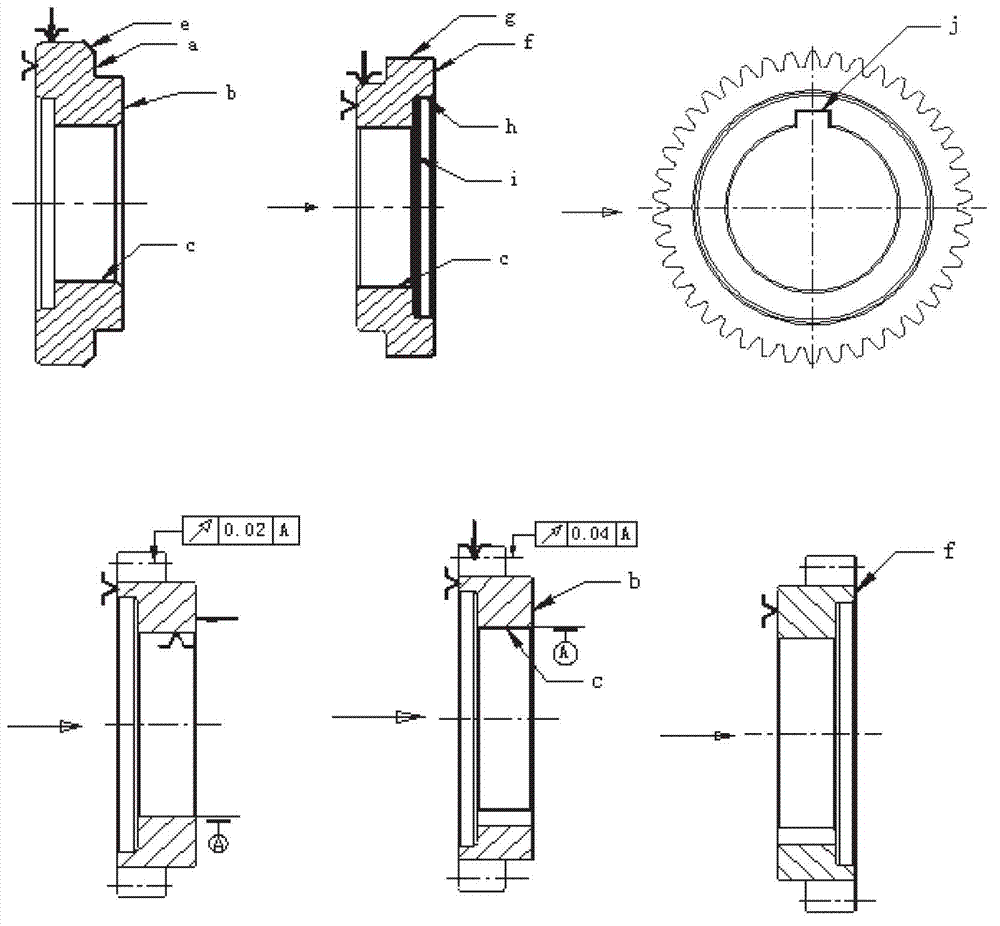

[0026] Referring to the accompanying drawings, a method for preparing gears for corrosion-resistant oil pumps includes the following steps:

[0027] 1) Casting and molding gear blanks, the weight percentages of the chemical components of each component are: C: 2.85-3.25%, Si: 1.2-1.5%, Mn: 0.8-1.2%, P: 0.6-0.8%, S: 0.05-0.07% , Cr 0.24-0.35%, Cu 0.7-0.9%, the balance is iron, the temperature of the casted gear blank is reduced to 300°C, then heated to 650-760°C, kept for 3-5 hours, cooled to 300°C, kept 4 hours, reheat to 650-760°C, keep warm for 17 hours, cool to 450°C at 50°C / hour, then cool to 140°C at 20°C / hour;

[0028] 2) Choose a CNC lathe, choose a carbide tool for the tool, and carry out the finishing turning of the large end a of the gear to 18.6±0.2mm, the small end b to 6.1±0.05mm, the outer diameter e to φ74.1±0.1mm and chamfering, Inner hole c to φ38.5±0.1 mm;

[0029] 3) Choose a CNC lathe, choose a carbide tool for the tool, and perform finish turning on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com