Transmission connector of electric bicycle

A technology for electric bicycles and transmission joints, which is applied to wheeled transmissions, rotary transmissions, vehicle components, etc., can solve problems such as personal injury, increased economic costs, trousers or skirts, chains or sprockets entangled or bitten, etc. Achieve the effect of increasing the contact area, preventing failure, and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

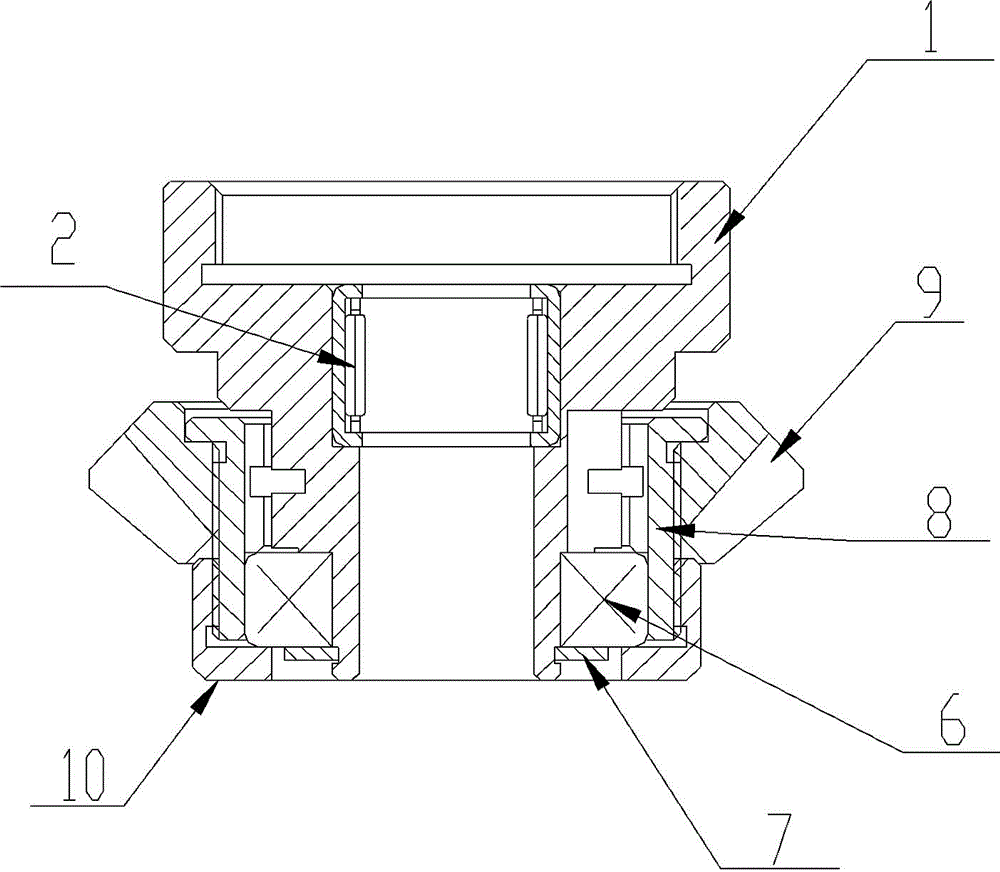

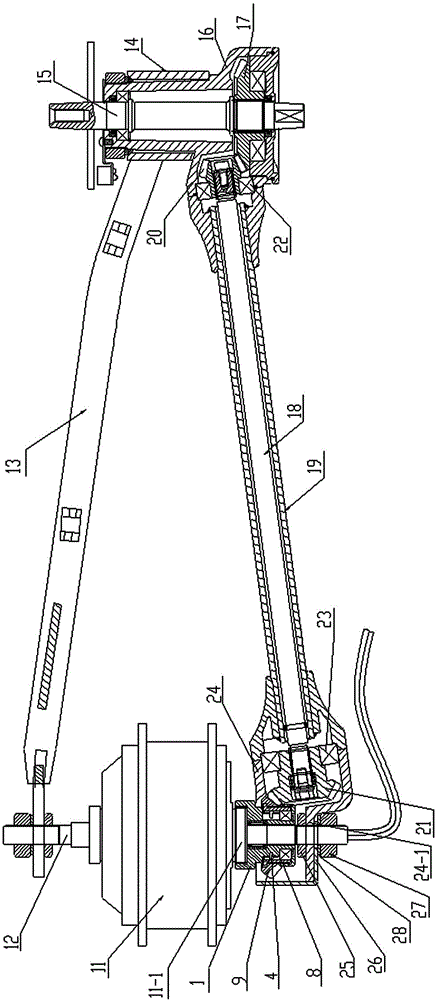

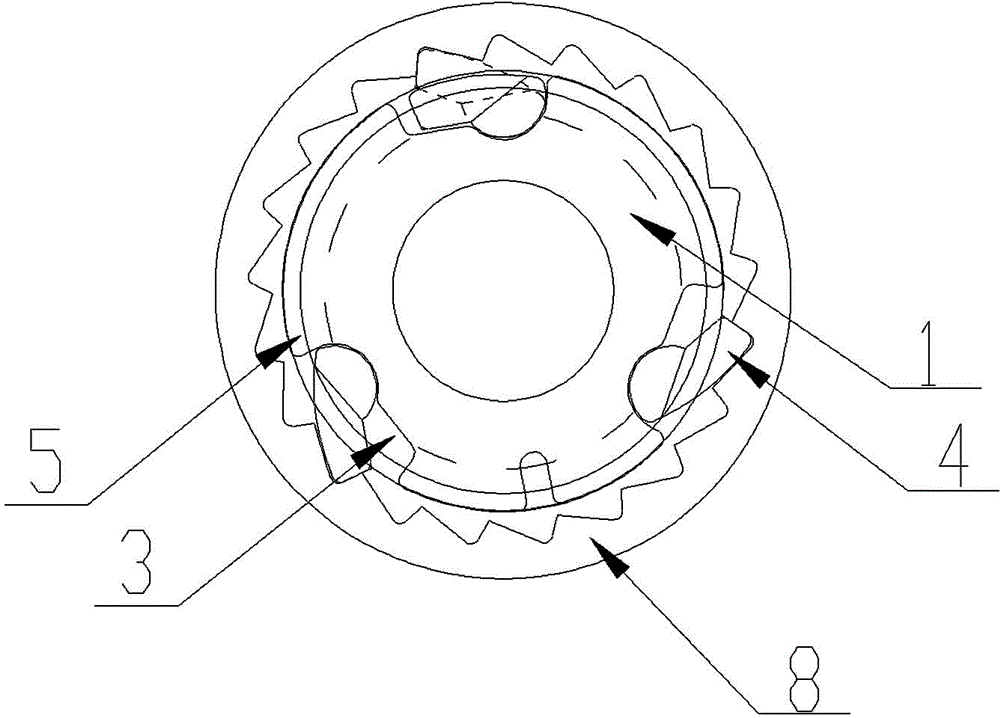

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] see Figure 1 to Figure 3 As shown, a transmission joint of an electric bicycle includes a connecting body 1, and the connecting body 1 is provided with at least three-stage stepped through holes. In this embodiment, the connecting body 1 is provided with three-stage stepped through holes, which is the best In the embodiment, the large-diameter section of the connecting body 1 is provided with an internal thread for connection, and the large-diameter section of the connecting body 1 is used to connect with the motor; the second stepped through hole of the connecting body 1 is provided with a The first bearing 2 installed on the support shaft of the electric bicycle is limited by the stepped through hole. The first bearing 2 adopts a needle bearing, and the connecting body 1 is slidably fitted to the electric bicycle through the first bearing 2. On the support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com