Mechanical continuously variable transmission for bicycles

A continuously variable transmission, bicycle technology, applied in bicycle gear shifting mechanisms, bicycle accessories, vehicle gearboxes, etc., can solve the problems of complex and changeable traffic conditions, and achieve the effect of reducing physical strength and rational use of power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

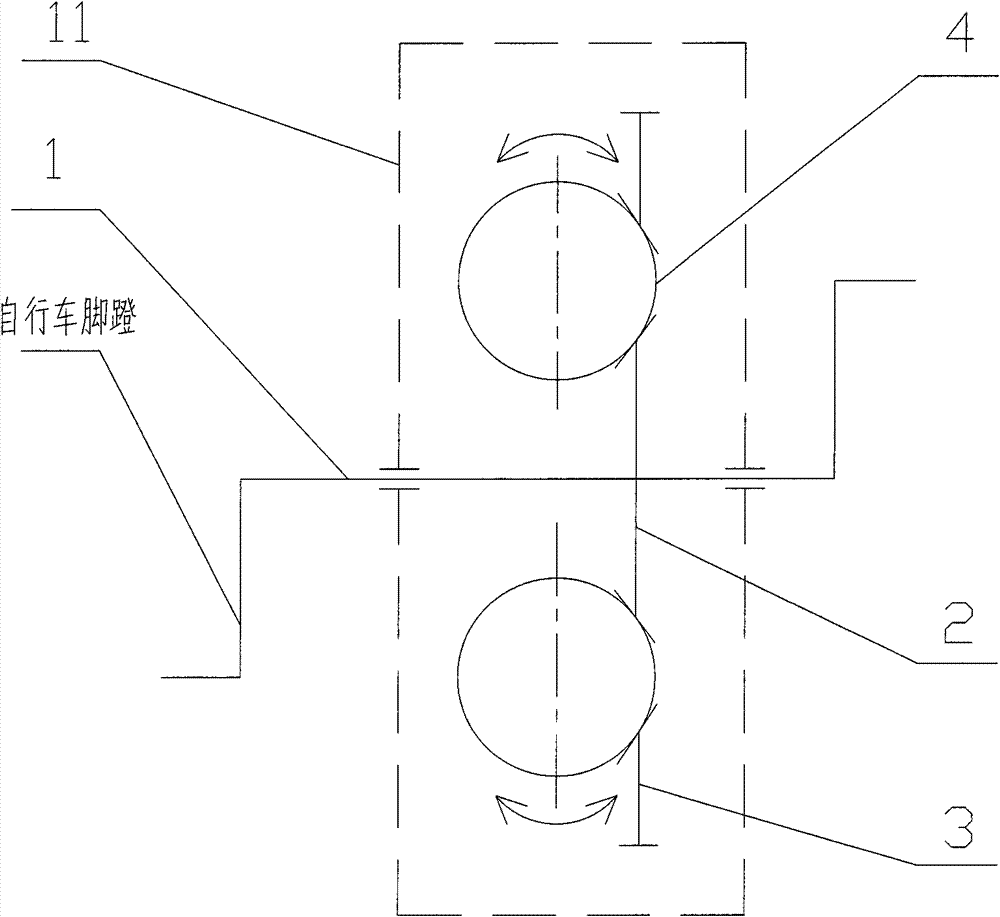

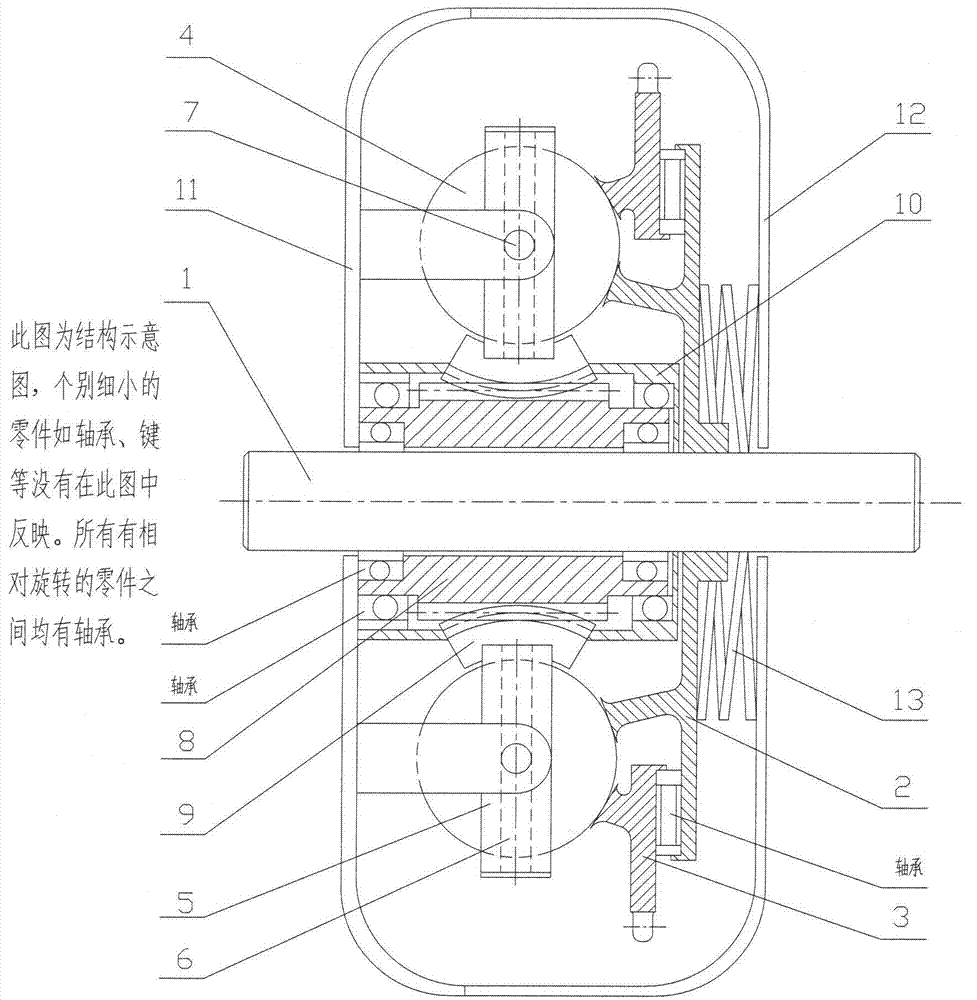

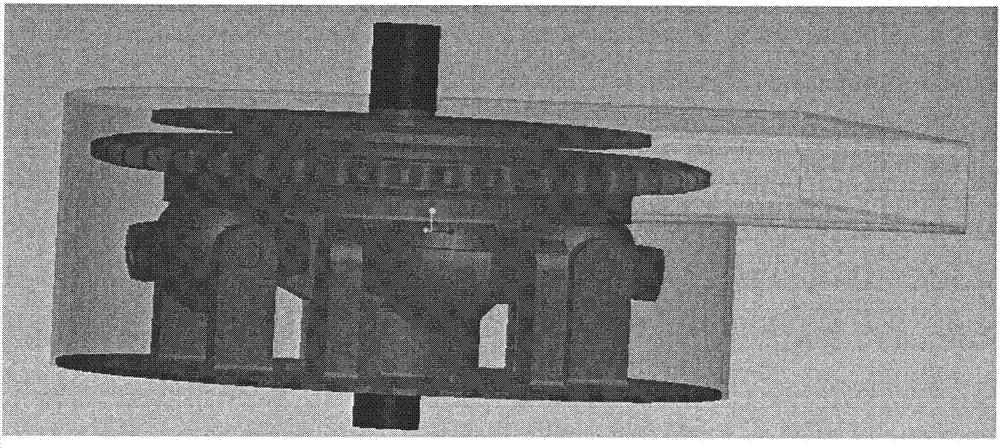

[0020] As shown in the figure, the base body (11) is fixed on the bicycle, and the transmission ball rack (5) is installed on the base body (11) through the supporting shafts (7) at both ends, and arranged around the center. Transmission ball (4) is installed on the transmission ball frame (5) by transmission ball shaft (6). The central speed-regulating worm (8) is installed in the center of the base body (11) through a bearing. A speed regulating worm gear (9) is fixedly connected on a transmission ball bracket (5), and meshes with the central speed regulating worm (8). The end cover (10) supports the other end of the central speed regulating worm (8) through a bearing, and is fixedly connected to the base body (11). The included angles of the rotation axes of all transmission balls (4) and the rotation axis of the central speed regulating worm are the same. The input shaft (1) passes through the central governor worm (8) and is mounted coaxially with it using bearings. Pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com