Compression control method for rear-loading garbage compression vehicle

A technology of garbage compression and compression control, which is applied to garbage receptacles, transportation and packaging, etc., can solve the problems of wasting manpower, high labor intensity, and complicated operation, and achieve the effect of saving manpower and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the latest step description of the present invention.

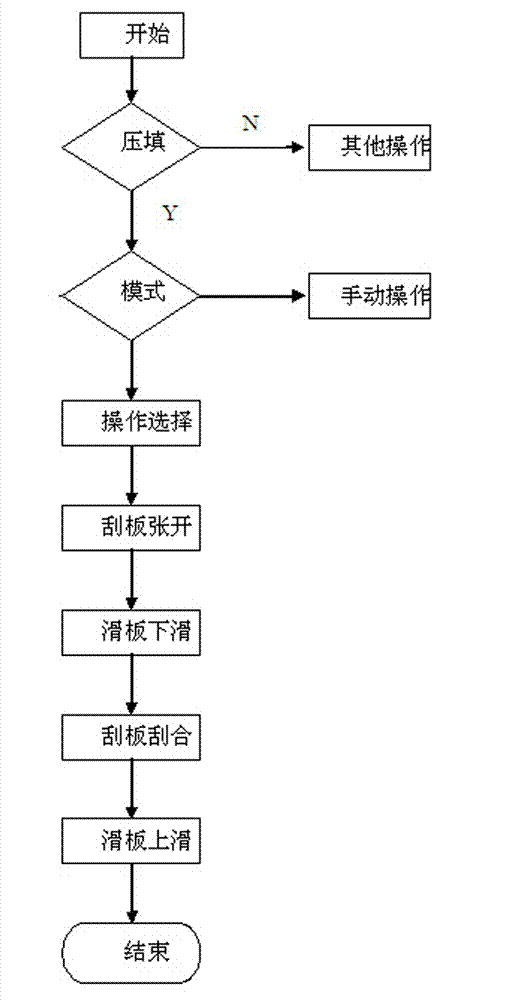

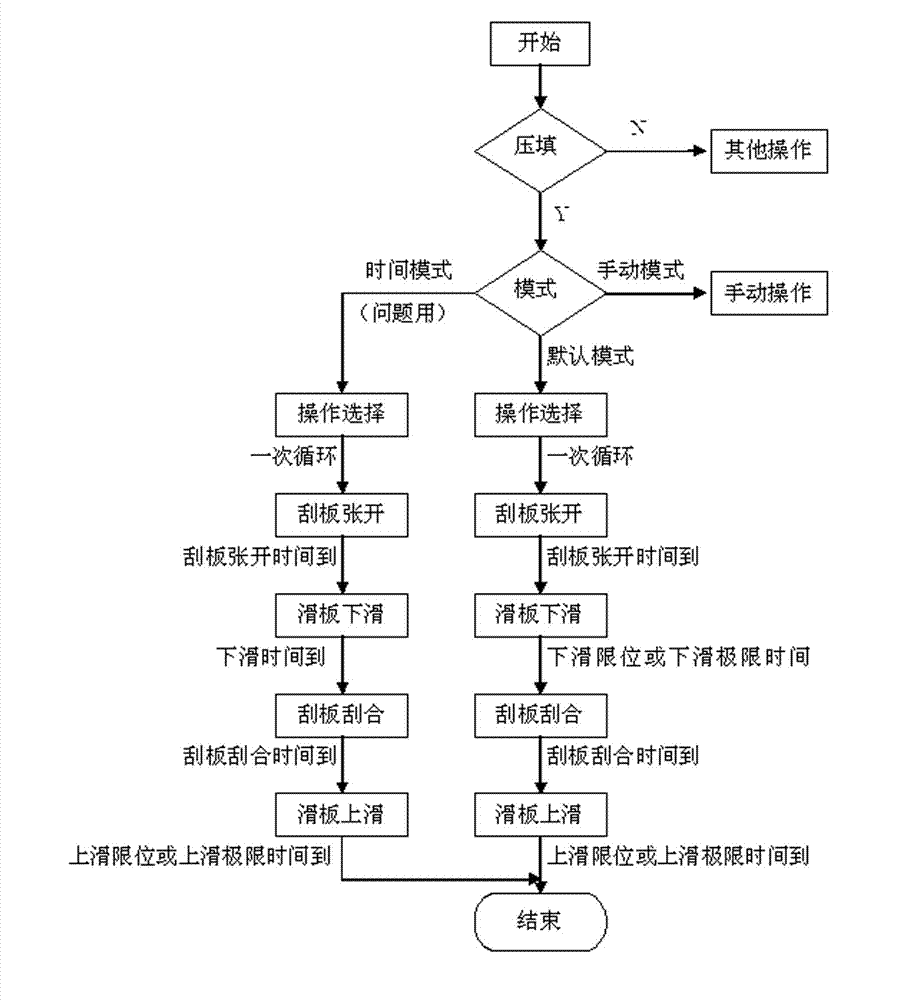

[0026] Such as figure 2 Shown, the present invention comprises the following steps;

[0027] 1) Press filling: press the press and fill button and time button on the operation box in the cab to close the button, and press and fill the garbage into the filler.

[0028] 2) Operation selection: Press the cycle button on the operation box of the jog filler to start a compression cycle.

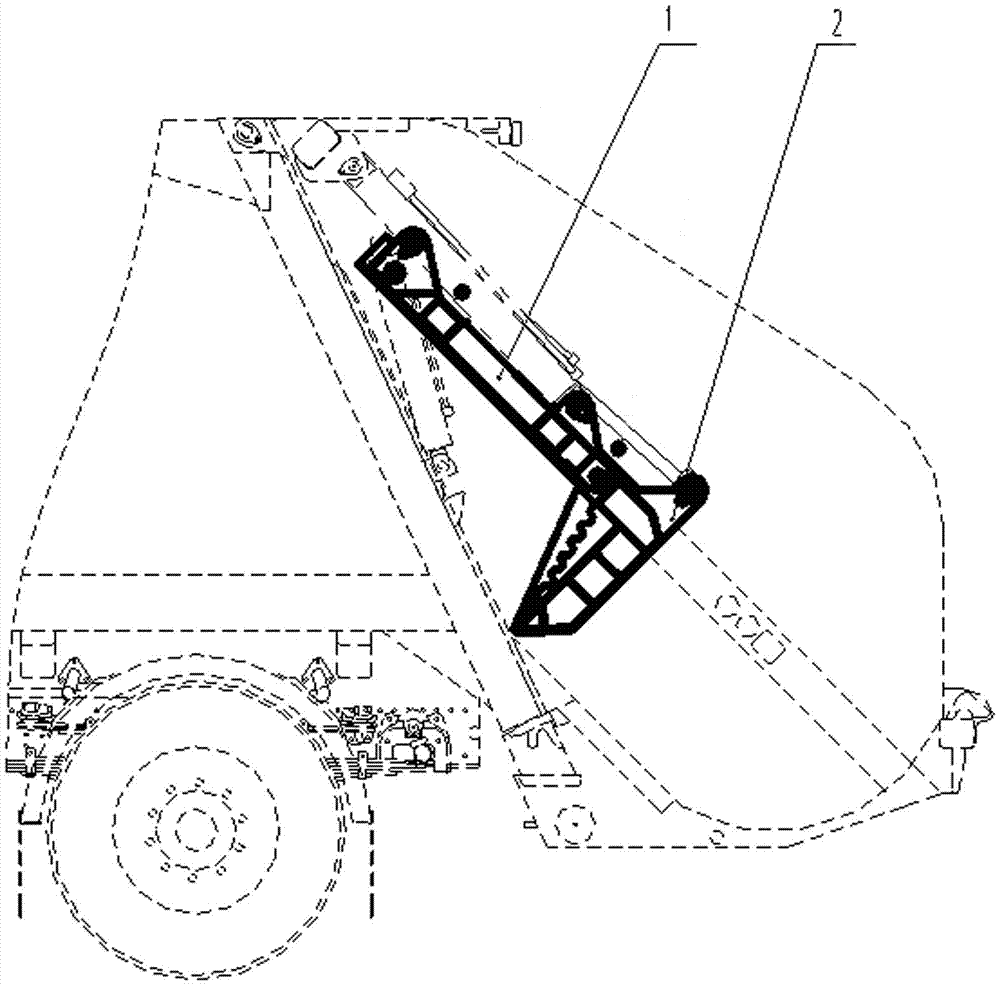

[0029] 3) Open the scraper 2: turn on the PLC controller to control the opening of the scraper 2.

[0030] 4) Sliding of skateboard 1: When the opening time of scraper 2 is over, the PLC controller controls the sliding of skateboard 1, and the control of skateboard 1 is controlled by time. This time ensures that skateboard 1 slides down to the point where it can be filled when scraper 2 scrapes together. The garbage in the loader is scraped into the half position.

[0031] 5) Scraper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com