Spring rubber support

A technology of rubber bearings and steel springs, which is applied to bridge parts, bridges, building components, etc., can solve the problem of returning the center of the upper and lower flange plates of the bearings to a vertical line, unable to reach the user's stiffness, and unable to be selected by the user Issues such as the size of the horizontal stiffness of the support, to achieve the effect of ensuring the traffic capacity and improving the vertical stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

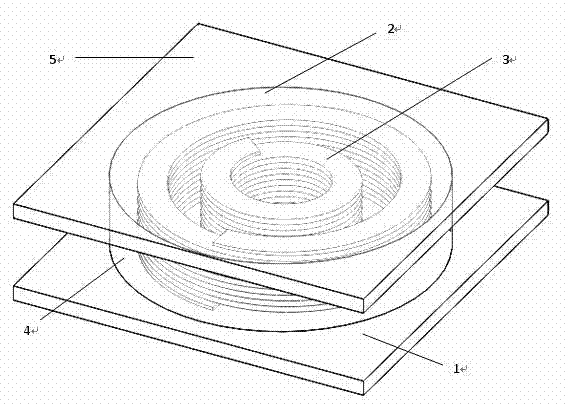

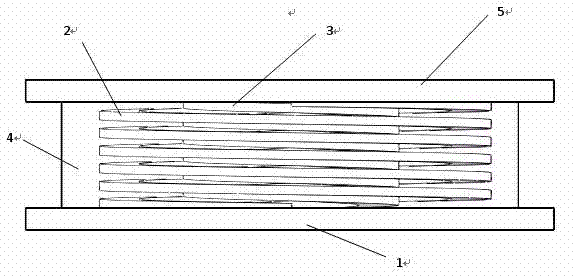

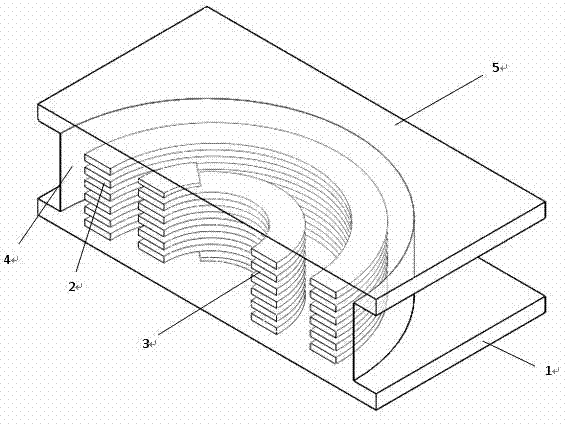

[0022] Example 1: Please see figure 1 , figure 2 with image 3 , The spring rubber bearing is composed of the upper flange plate 1, the first inner steel spring 2, the second inner steel spring 3, the rubber layer 4, and the upper flange plate 5.

[0023] As one of the technical points of the present invention, the first inner steel spring 2 and the second inner steel spring 3 are sleeved in a horizontal plane. The first inner steel spring 2 has a larger diameter than the second inner steel spring 3.

[0024] As one of the technical points of the present invention, the first internal steel spring 2, the second internal steel spring 3 and the rubber layer 4 are vulcanized together.

[0025] As one of the technical points of the present invention, the lower ends of the first inner steel spring 2 and the second inner steel spring 3 are reliably connected with the lower flange plate 1, and the upper end is reliably connected with the upper flange plate 5.

[0026] As another variation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com