Adjustable clip assembly and roof connecting structure

A technology for connecting structures and clips, which is applied to roofs, building structures, roof coverings, etc., can solve problems such as inconvenience, and achieve the effects of convenient disassembly and maintenance, low manufacturing cost, and quick installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

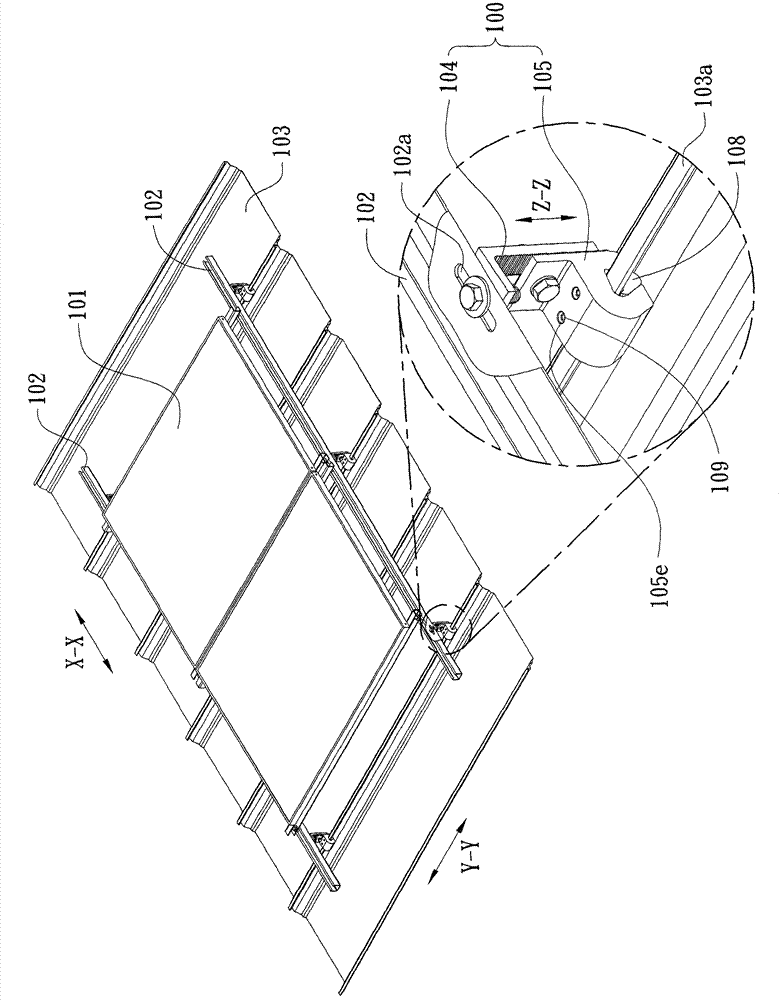

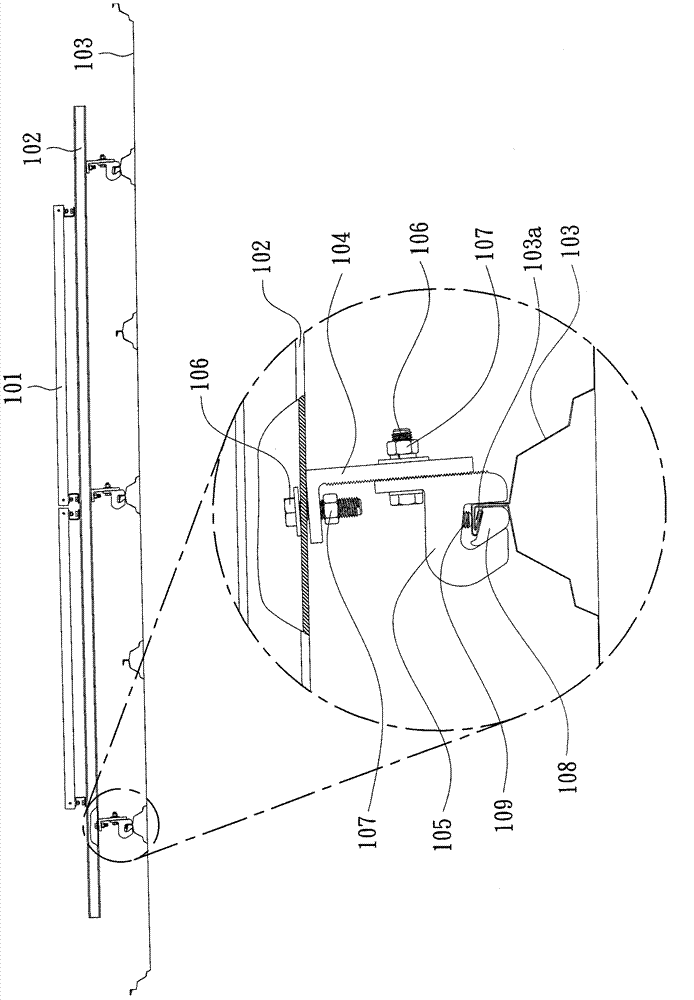

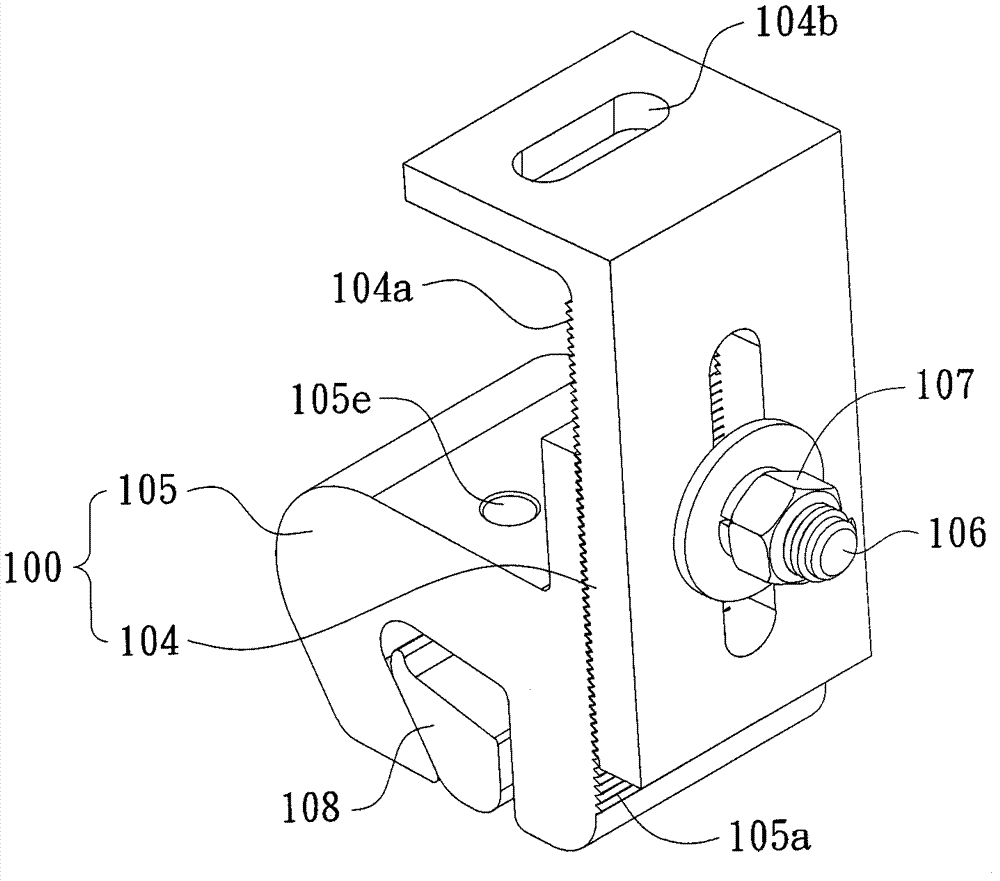

[0055] Please also refer to figure 1 and figure 2 , figure 1 is an enlarged view showing a solar cell panel installed on a metal roof and an adjustable clip assembly according to an embodiment of the present invention, figure 2 is to draw figure 1 Side view of , and enlarged view of the adjustable clip assembly section. The adjustable clip assembly 100 and the support beam 102 form a roof connection structure for fixing the solar cell panel 101 . The roof connection structure can also easily allow other devices (such as a distribution box or an air conditioner fan) to be locked to the support beam 102 , and is not limited to locking solar panels. A plurality of adjustable clip assemblies 100 are used to fasten the connecting beam 102 to the seam 103 a on a roof 103 . The connecting beam 102 may be a C-shaped beam, a channel steel, an angle steel, an I-shaped steel, a Z-shaped steel or a rectangular tube and the like. The connecting beam 102 can be made of metal, fiberg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com