Hoisting method for long-span asymmetrical rectangular spatial twisted pipe truss

A technology of space distortion and hoisting method, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of laborious, high-altitude installation safety hazards, time-consuming and other problems, and achieve shortened construction period, reduced construction cost, and simple installation work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A hoisting method for a large-span asymmetrical rectangular space-distorted pipe truss is completed according to the following steps:

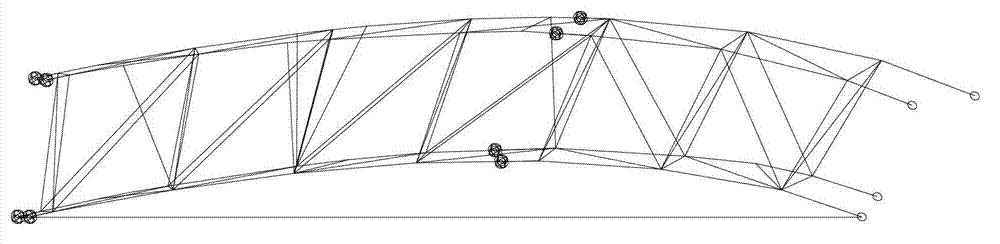

[0021] ① Establish the space solid model of the hoisting section of the space twisted truss, such as figure 1 shown;

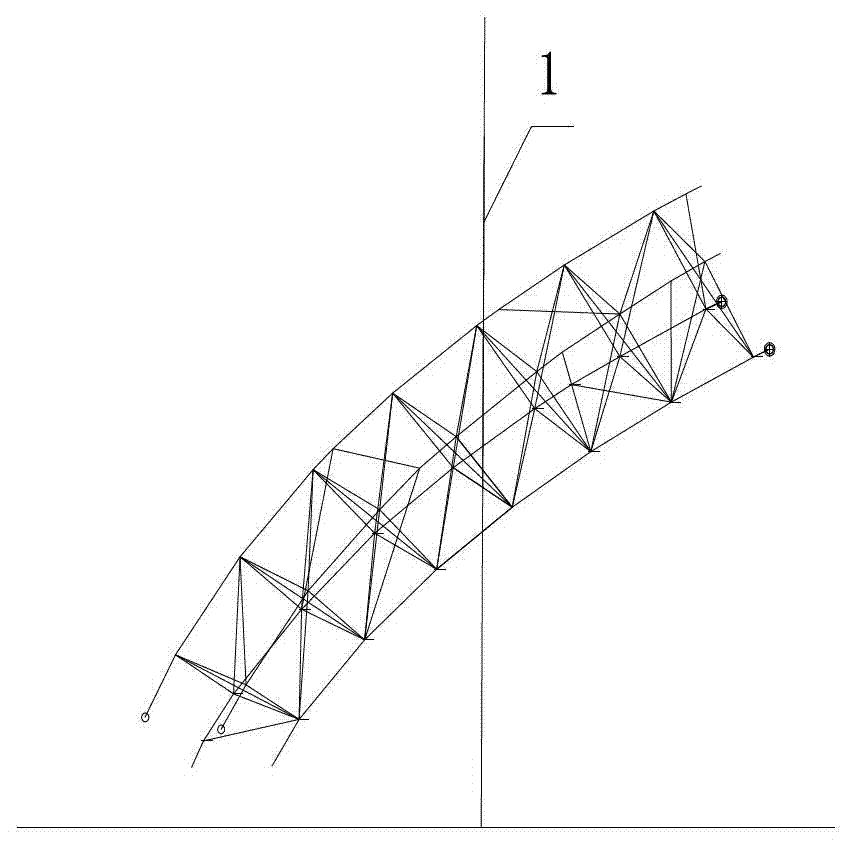

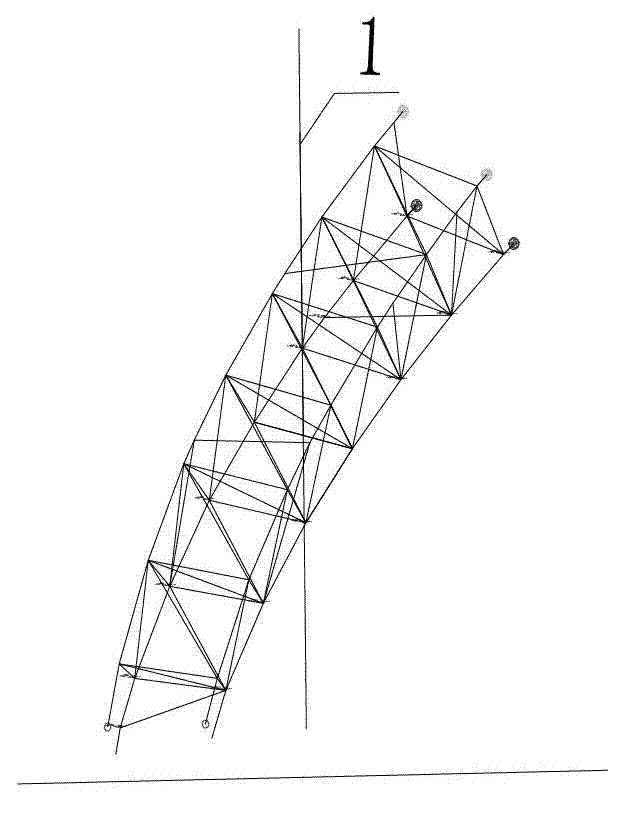

[0022] ② Find out the position of the space center of gravity in the twisted state in the truss construction drawing, such as figure 2 , 3 shown;

[0023] ③ Use the center of gravity and a certain point on the vertical line 1 of the horizontal plane as the center to draw a straight line to the upper chord of the truss to ensure that the angle between the straight line and the vertical line is controlled between 30 and 60 degrees, such as Figure 4 , 5 shown;

[0024] ④According to the determined lifting point position, analyze each binding point of the truss, that is, the maximum value of the force state of each point during the lifting process of the truss lifting point, so as to determine the type and length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com