Bidirectional punching method for underground excavation of subway station

A subway station and underground excavation technology, which is applied in the direction of earth drilling, underground chambers, mining equipment, etc., can solve the problems of shortening the construction period, increasing the direct consumption of the project and increasing the construction cost, so as to shorten the construction period and avoid the effect of group caves , reduce the effect of lateral convergence deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. Those skilled in the art should understand that the following examples are illustrative and not restrictive.

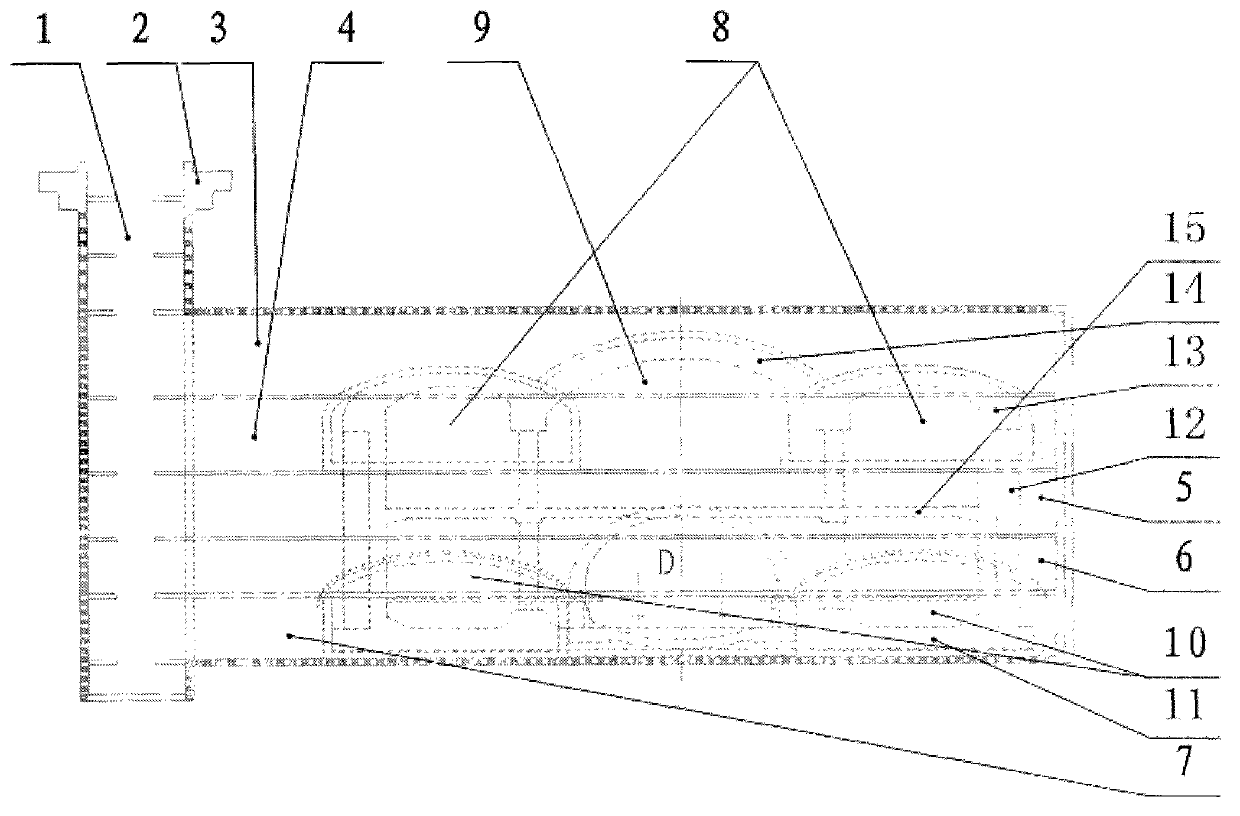

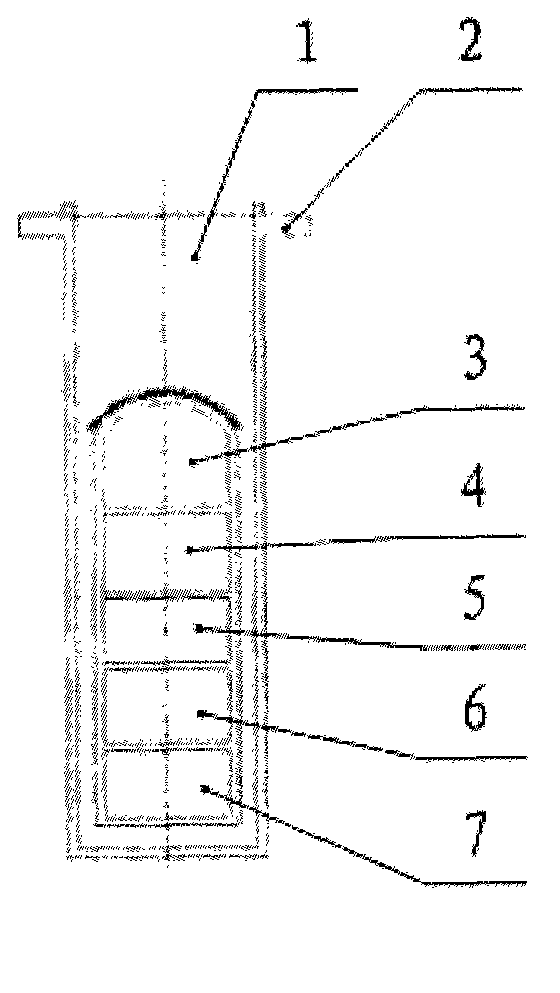

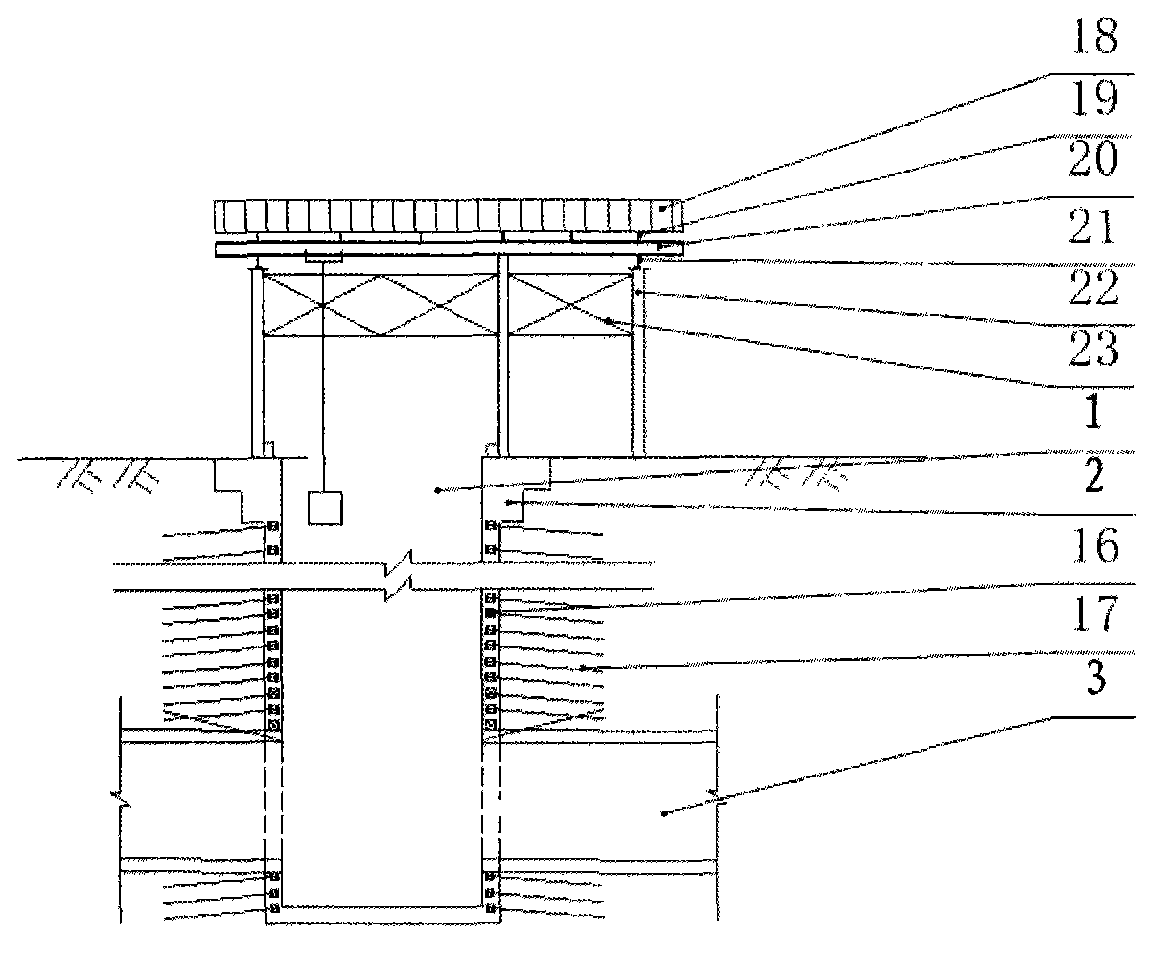

[0086] The components shown in the figure are the existing tunnel D, the vertical shaft 1, the locking ring beam 2, the fifth floor cross passage 3, the fourth floor cross passage 4, the third floor cross passage 5, the second floor cross passage 6, the fifth floor cross passage First-floor cross passage 7, upper pilot tunnel 8, middle pilot tunnel 9 on the upper part of the upper pilot tunnel, lower pilot tunnel 10, lower pilot tunnel floor 11, side piles 12, main side arch secondary lining 13, middle arch concrete 14, middle plate 15. Grid 16, grouting small conduit 17, room frame 18, I-steel transverse suspension beam 19, I-steel track beam and longitudinal beam 20, I-steel beam 21, steel pipe column 22, channel steel connection reinforcemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com