Air feeding device of mining car engine

An air intake device and engine technology, applied in the direction of fuel air intake, etc., can solve the problem of engine air intake is not smooth, and achieve the effect of small resistance, smooth air intake and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

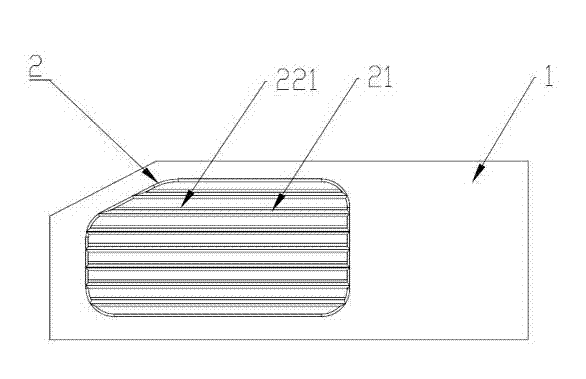

[0010] Aiming at the boiling phenomenon of the mine vehicle engine water tank in the prior art, the present invention innovatively proposes a mining vehicle engine air intake device, which adopts a large-area air intake grille, so that the air intake grille can smoothly enter the air and have low resistance The utility model has a good cooling effect on the engine water tank of the mining vehicle, and solves the problem of unsmooth air intake of the engine of the mining vehicle in the prior art.

[0011] Such as Figure 1~2 As shown, a mining vehicle engine air intake device is installed at the air intake of the mining vehicle engine. The air intake device includes a frame 1 and a net cover 2. In particular, the net cover 2 is provided with a plurality of strip screens 21 , and the total transparent area of the strip sieve 21 is at least greater than 1 / 2 of the area of the net cover, so that the net cover has the advantage of a large air inlet area.

[0012] In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com