Multipurpose on-tower pulley hanger

A kind of pulley and hanging board technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of poor safety, lifting point displacement, insecurity, etc., to achieve the effect of convenient operation, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

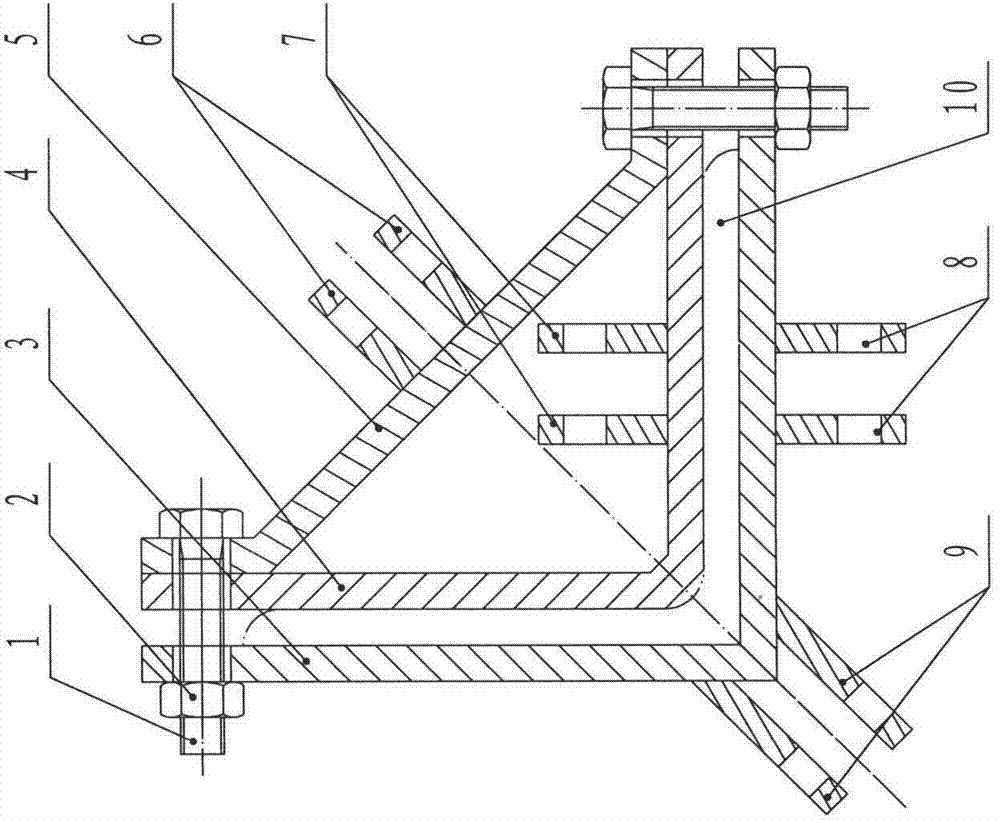

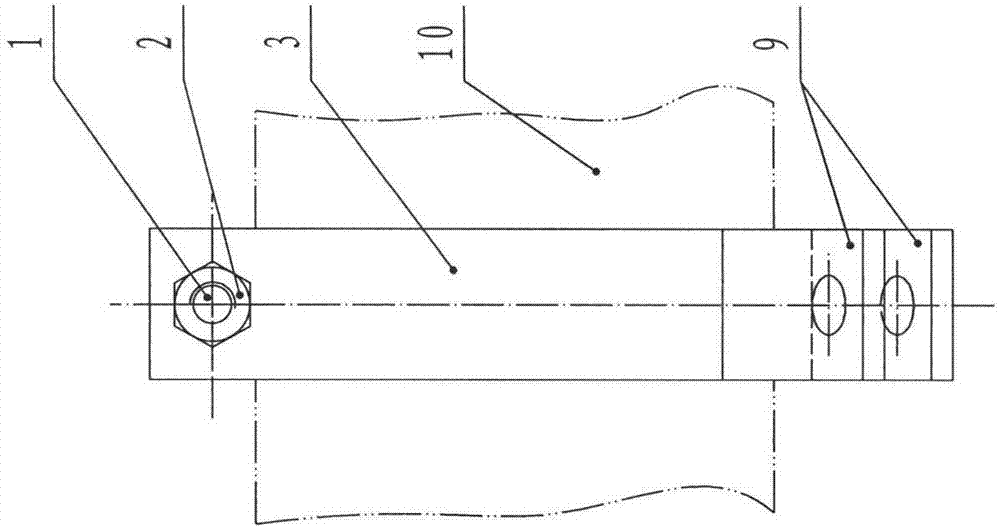

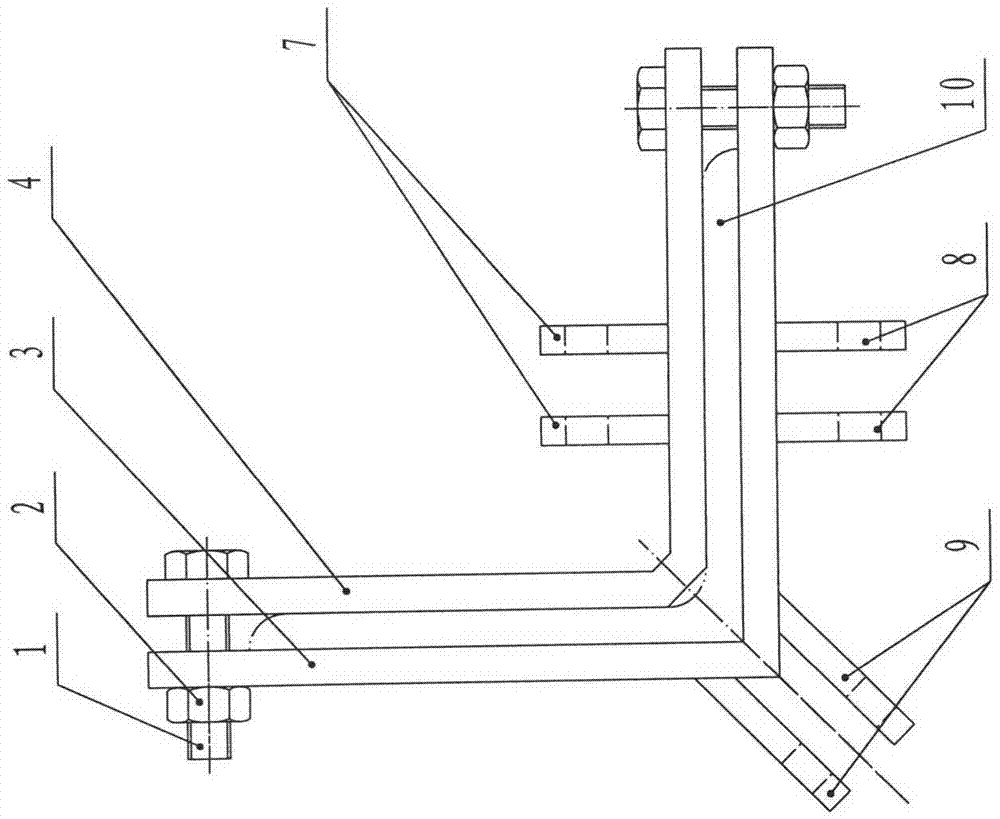

[0014] Such as figure 1 , figure 2 As shown, the multi-purpose tackle hanger on the tower of the present invention comprises outer curved plate 3, inner curved plate 4, inclined curved plate 5, No. 1 hanging point 6, No. 2 hanging point 7, No. 3 hanging point 8 and No. 4 hanging point 9 . The outer bending plate 3 and the inner bending plate 4 are two angle steel-shaped 90° bending plates. The angle between the planes is 90°. Both ends of the three bent plates are provided with connecting holes. When assembling, the outer bent plate 3 and the inner bent plate 4 are respectively placed on the outer and inner sides of the iron tower angle steel 10, and the inclined bent plate 5 is placed on the inner bent plate 4. On the inner side, the three bent plates are connected as a whole by bolts 1 and nuts 2 and fixed on the iron tower angle steel 10. There is No. 1 hanging poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com