A multi-purpose miniature voice coil motor

A voice coil motor, multi-purpose technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of increasing the cost of the motor, affecting the focusing effect, and the welding quality cannot be guaranteed, and achieving the effect of increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

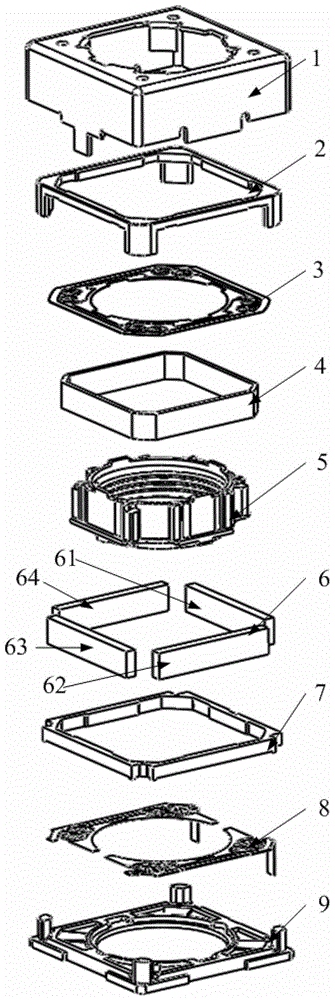

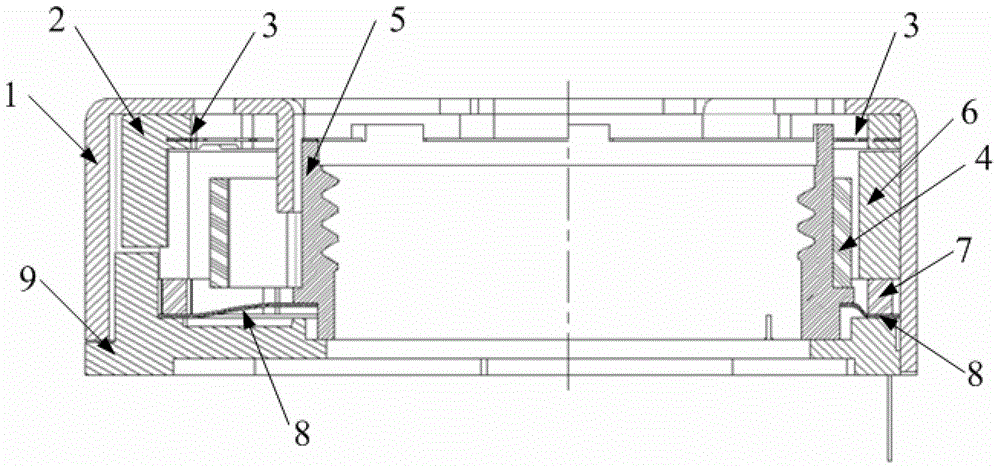

[0075] Such as Figure 1-14 As shown, the multipurpose miniature voice coil motor described in this embodiment includes a yoke body 1, a first gasket 2, an upper shrapnel 3, a coil 4, a bobbin 5, a permanent magnet 6, a second gasket 7, Lower shrapnel 8 and base 9.

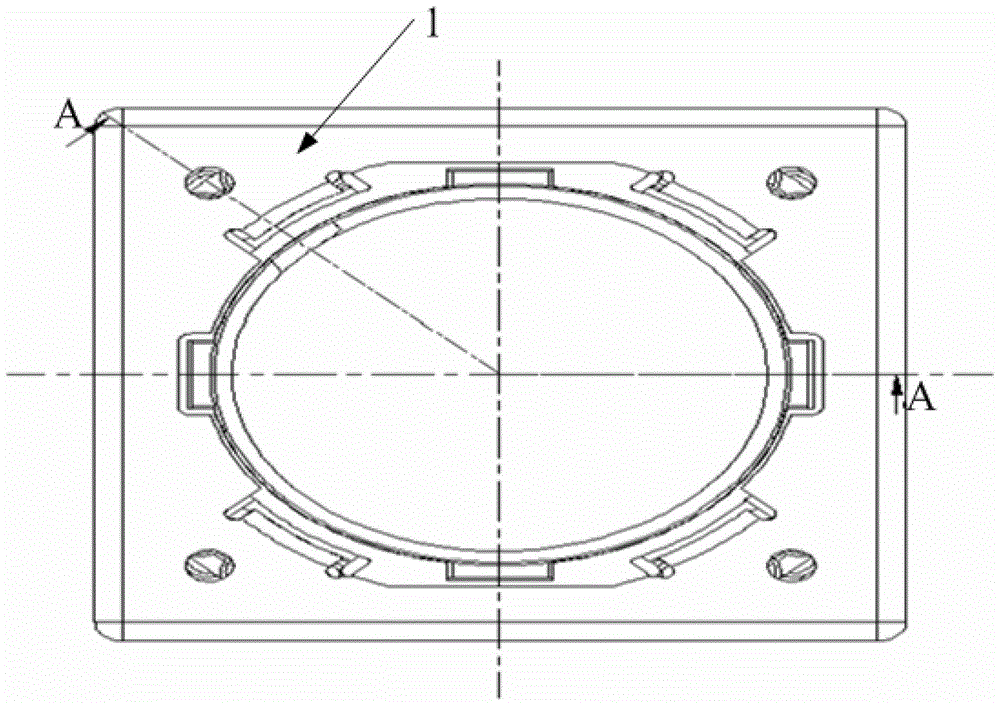

[0076] Such as Figure 5-6 As shown, the yoke body 1 includes a square yoke bottom plate 12, a yoke side frame 13 is arranged on the yoke bottom plate 12, a yoke through hole 14 is arranged in the center of the yoke bottom plate 12, and a yoke through hole 14 is arranged around the periphery of the yoke through hole 14. On the same side of the side frame 13, four yoke columns 15 are arranged circularly, and the four yoke columns 15 are arranged in parallel with the four corners of the yoke side frame 13 respectively. A yoke groove 16 is provided on one side of the frame 13 .

[0077] In this embodiment, the yoke body 1 is made of metal with high magnetic permeability and good ductility, preferably copper.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com