Floating ball device for drawing liquid medicine

A floating ball and potion technology, which is used in the secondary treatment of printed circuits, etc., can solve the problem of difficulty in controlling the distance between the suction pipe and the bottom of the tank, and achieve the effect of being conducive to repeated use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

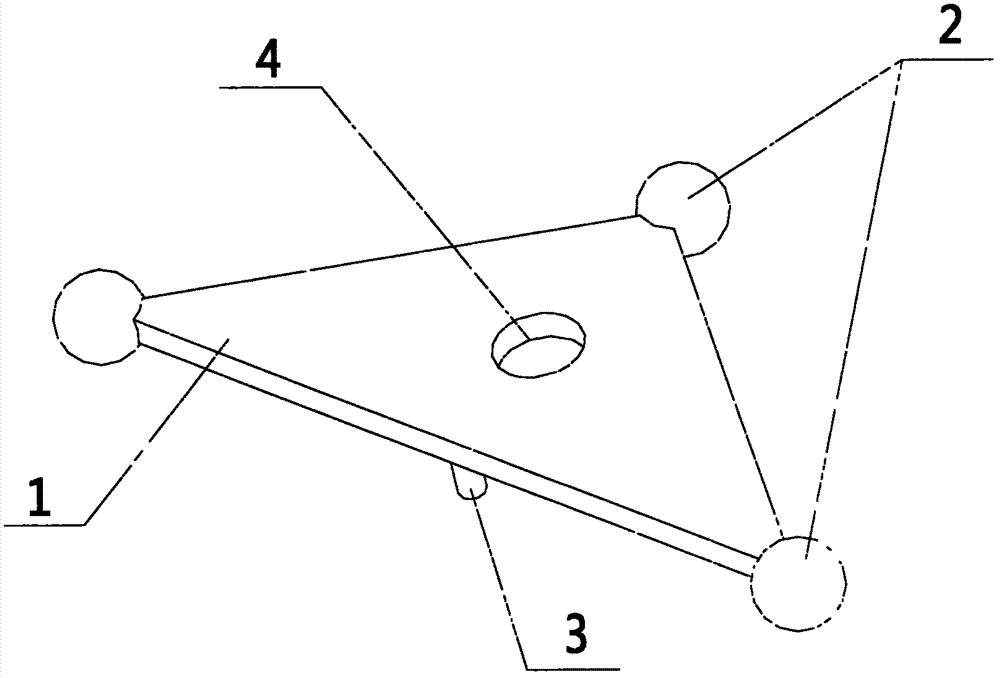

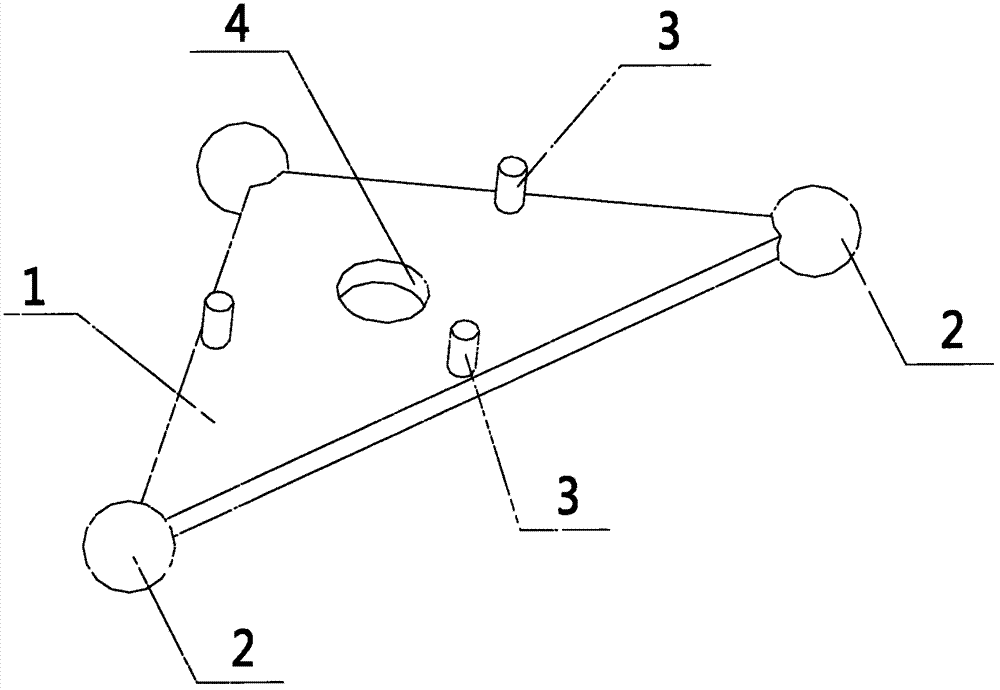

[0014] attached figure 1 , 2 It is a floating ball device for pumping liquid medicine according to the present invention, comprising a floating ball 2 and a foot plate 1; the floating ball 2 is connected with the foot plate 1 as a whole, and can be suspended in the liquid medicine; the foot plate 1 The bottom of the base is fixed with a foot post 3; the height of the foot post 3 is 10 centimeters; the foot plate 1 is provided with a connection hole 4 for connecting the air pump water pipe; the shape of the foot plate 1 is a triangle; the floating The ball 2 is fixed on three corners of the base plate 1; there are three base columns 3 .

[0015] When working, connect the suction pipe of the air pump to the connection hole 4. During the process of pumping liquid, the floating ball 2 drives the foot plate 1, and it descends with the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap