Manufacturing methods for components made of composite materials

A composite material and component technology, which is applied to the components of pumping devices for elastic fluids, pump components, household components, etc., can solve the problem that the last layer of fibers is not very suitable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

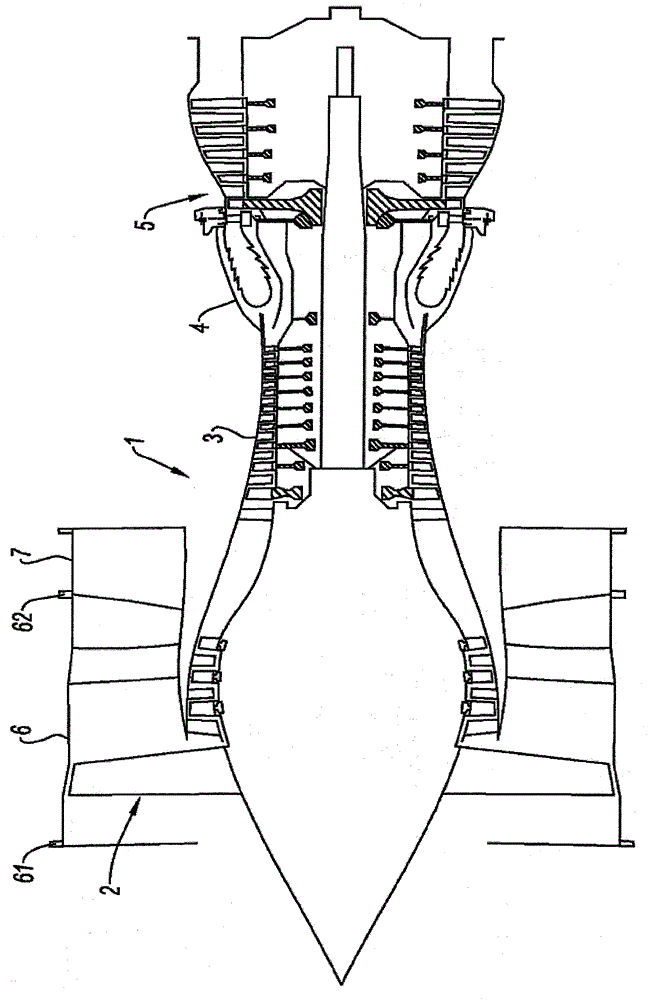

[0025] The invention applies to the manufacture of bypass turbojet fan casings, examples of which are figure 1 shown. The engine includes—from upstream to downstream, along the direction of gas flow—a front fan 2 at the engine inlet, an intake compressor, a high-pressure compressor 3, a combustion chamber 4, and high-pressure and low-pressure turbines 5 . The fan 2 is driven to rotate by a turbine (turbineBP) inside the fan case 6 . The fan case forms the volume of air that enters the engine interior. A portion of said air constitutes the main air flow, which is guided inside the engine to be successively compressed by the intake compressor and the high-pressure compressor. The air enters the combustion chamber 4 where its energy is enhanced by the combustion of fuel. The resulting gas is expanded in the subsequent turbine stage 5 and then injected. The other part of the air constitutes the auxiliary air flow, which is injected into the atmosphere directly or after meeting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com