Filter for processing grinding fluid

A filter and grinding fluid technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of clogging pipes, pools, time-consuming and laborious, and affecting normal production, etc., so as to facilitate recycling, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

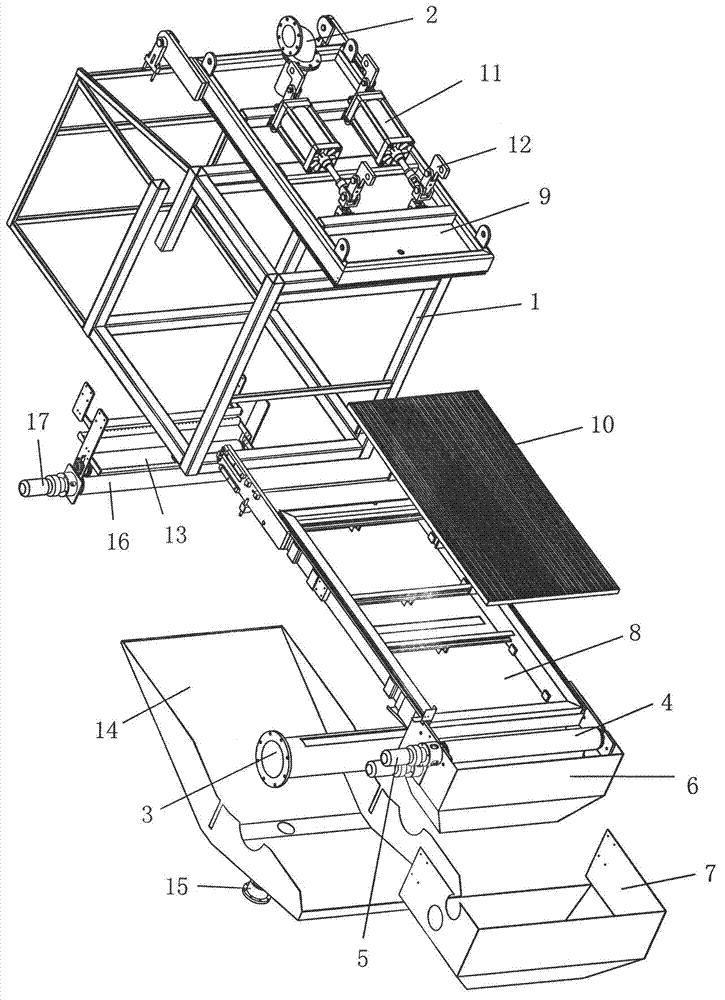

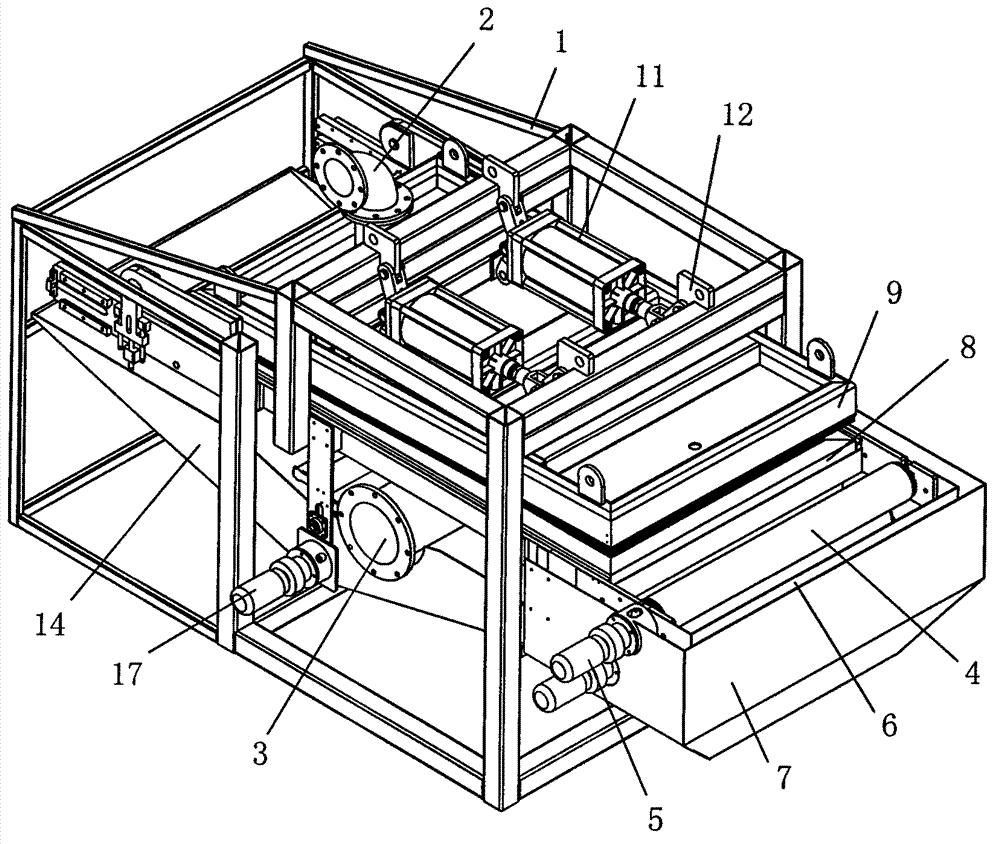

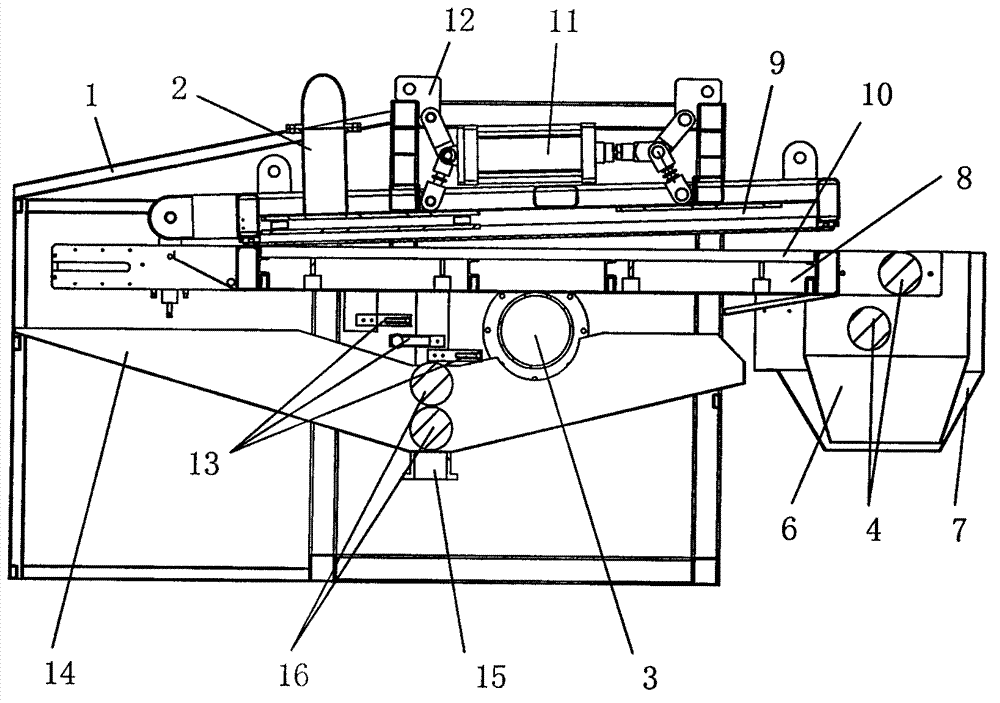

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] refer to figure 1 , figure 2 , image 3 , a filter for processing grinding fluid, comprising a frame 1, the frame 1 is provided with a box body, the box body is provided with a water inlet and a water outlet, the water inlet is connected to the water inlet pipe 2, and the The water inlet pipe 2 is provided with a control valve, the control valve can be a butterfly valve, the water outlet is connected to the water outlet pipe 3, and a mesh (not shown) is worn in the box, and the two ends of the mesh extend After exiting the box body, it forms a circle and is driven by a rotating mechanism to rotate. The water inlet and water outlet are respectively located on both sides of the mesh cloth, and the frame body 1 is located on the outside of the box body and is located on the One side of the moving direction of the mesh cloth is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com