Grinding wheel dressing fixture for machining involute profile spline

A grinding wheel dressing and surface patterning technology is used in manufacturing tools, metal processing equipment, parts of grinding machine tools, etc. It is easy to process, easy to use, fast and safe, and convenient for the operator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

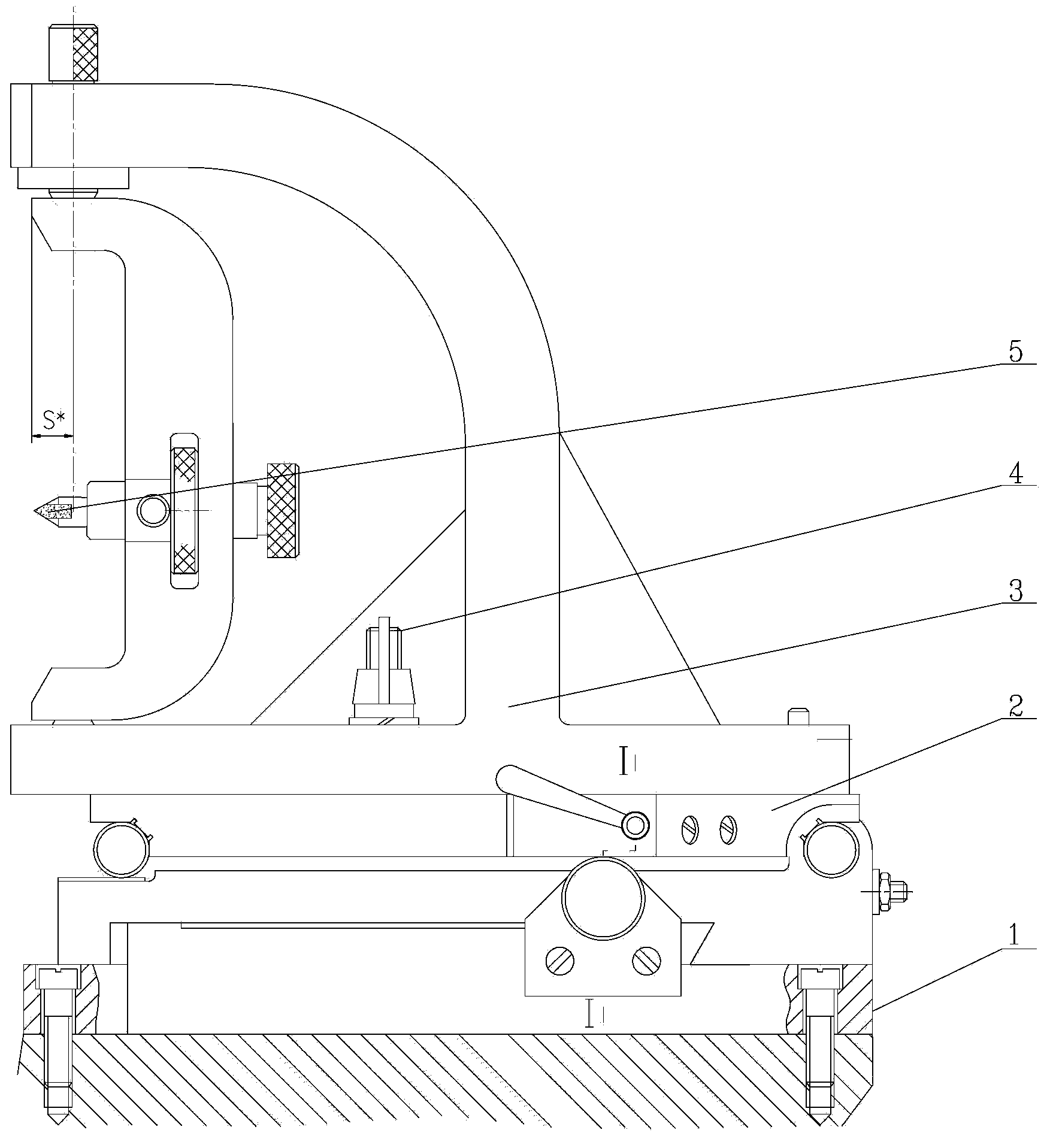

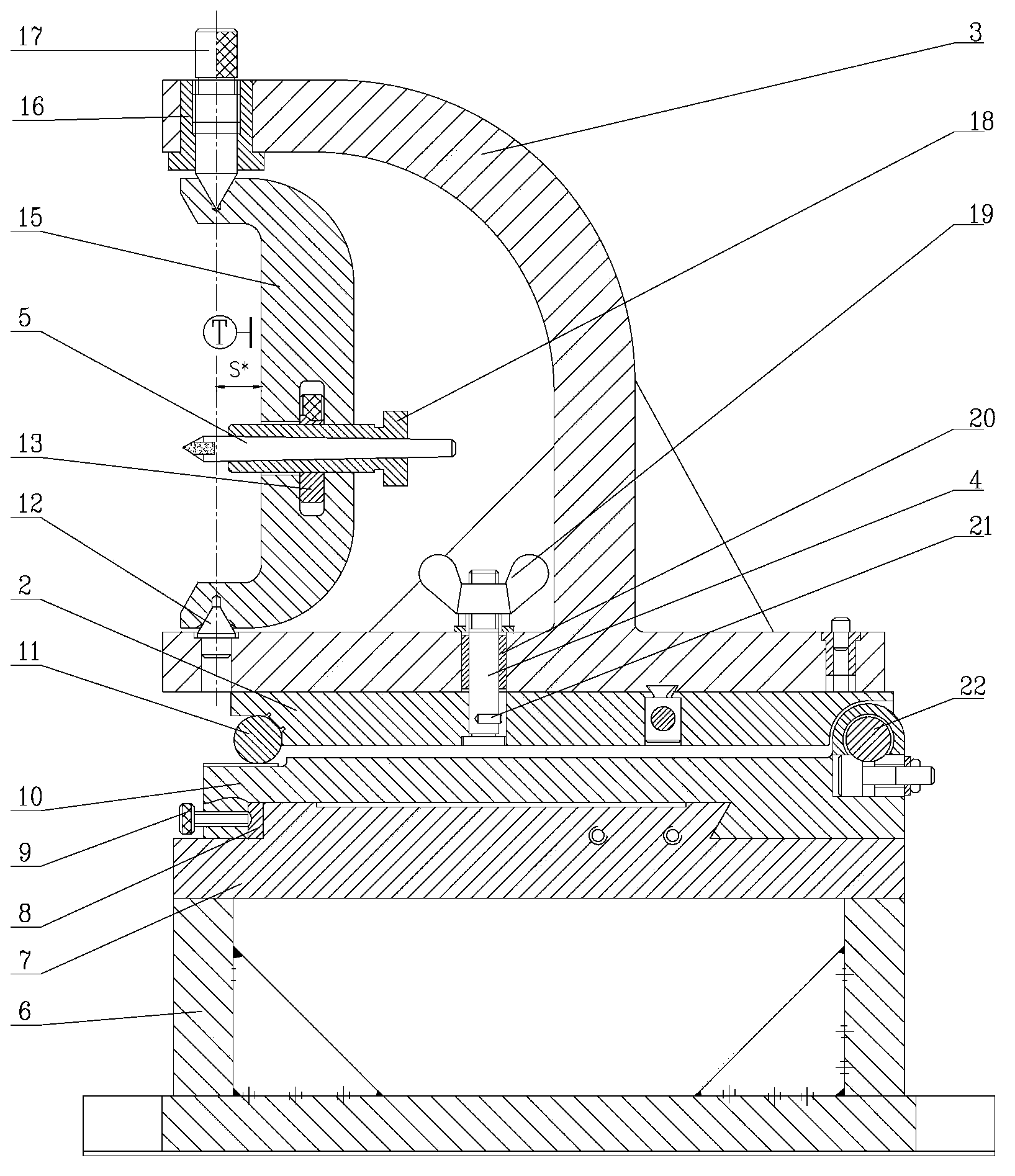

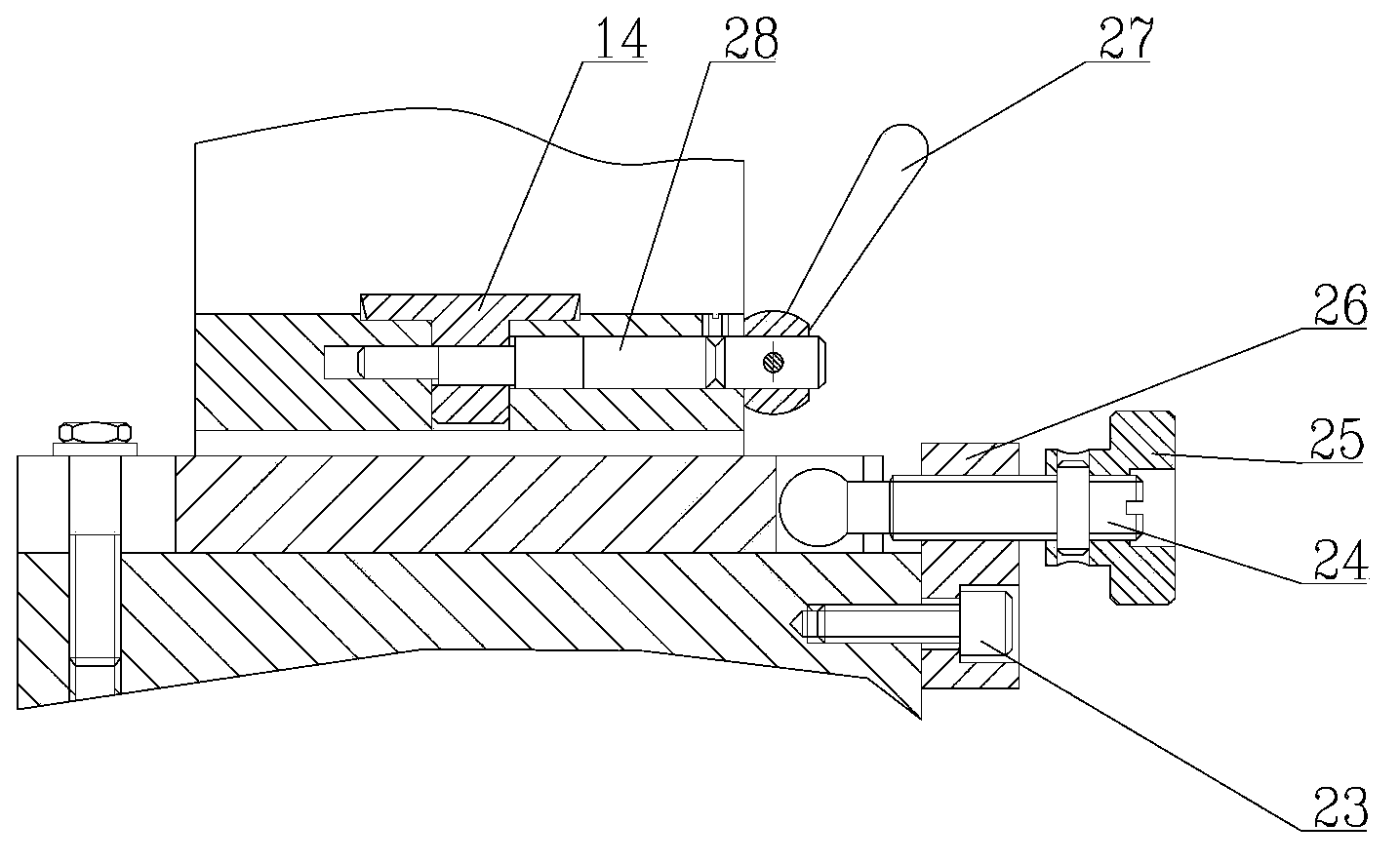

[0024] Example. Grinding wheel dressing fixture for processing involute profile splines, composed of Figure 1-3 As shown, it includes the adjustment base 1, the adjustment base 1 is provided with a swivel seat 2, the swivel seat 2 is provided with a swivel seat 3 via the mandrel 4, and the upper and lower positions of the swivel seat 3 are oppositely provided with an adjustable top 17 and a fixed top 12, A pendulum 15 is provided between the adjustable top 17 and the fixed top 12, and a diamond 5 is provided in the middle of the pendulum 15.

[0025] Described adjustment base 1 comprises bracket 6, and bracket 6 is provided with base plate 7, and base plate 7 is positioned with adjusting plate 10 through dovetail groove, is provided with wedge 8 positioning between base plate 7 and adjusting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com