Ferry push car

A ferry car and frame technology, applied in the direction of conveyor control devices, conveyor objects, conveyors, etc., can solve the problems of difficult positioning of the ferry car, low work efficiency, labor and material resources, and achieve accurate ferrying and automation Effect of controlling and eliminating cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

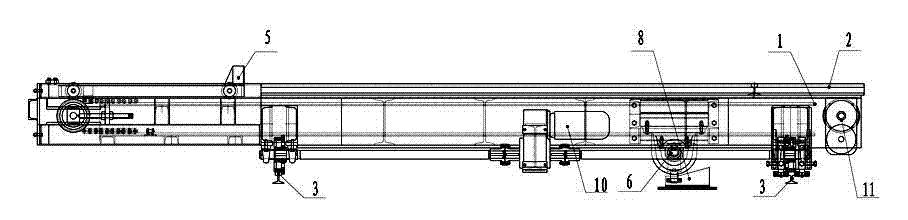

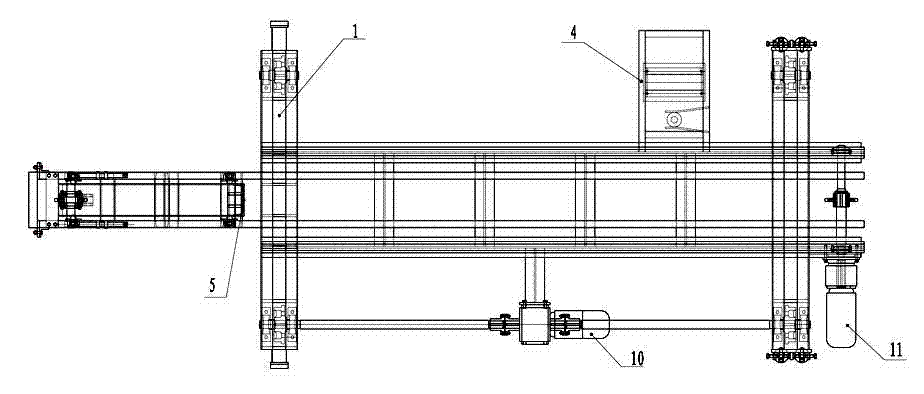

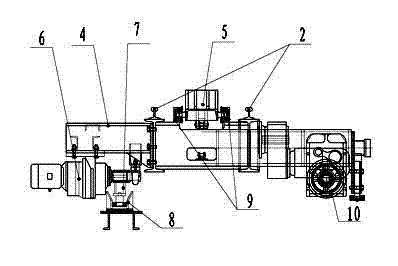

[0012] Such as figure 1 , 2 , 3, the ferry car of the present invention comprises an I-shaped vehicle frame 1 and a ferry guide rail 2, and two parallel ferry guide rails 2 are longitudinally provided on the said I-shaped vehicle frame 1, and the I-shaped vehicle frame 1 below There are two walking guide rails 3 perpendicular to the ferry guide rail 2 space, and the side of the bottom of the I-shaped vehicle frame 1 is equipped with a power device that drives it to move laterally along the described walking guide rails 3; Positioning bracket 4 is installed on the side; Positioning device is provided at the bottom of described positioning bracket 4; The positioning platform 8 installed on the ground; the I-shaped vehicle frame 1 is located in the middle of the two ferry guide rails 2 and is provided with a push trolley track 9 in parallel; The push motor 11 that dolly track 9 moves.

[0013] During operation, when the ferry I-shaped frame 1 is driven by the main motor 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com