Hinge joint assembly of sealed centripetal oscillating bearing steel structure

A joint bearing and steel structure technology, which is applied in the direction of building structure and construction, can solve the problems that the stress of rigid structures cannot be eliminated, and achieve the realization of three-way stress in space and hinged connection performance, stress elimination, and external shear force elimination. Effect of additional bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

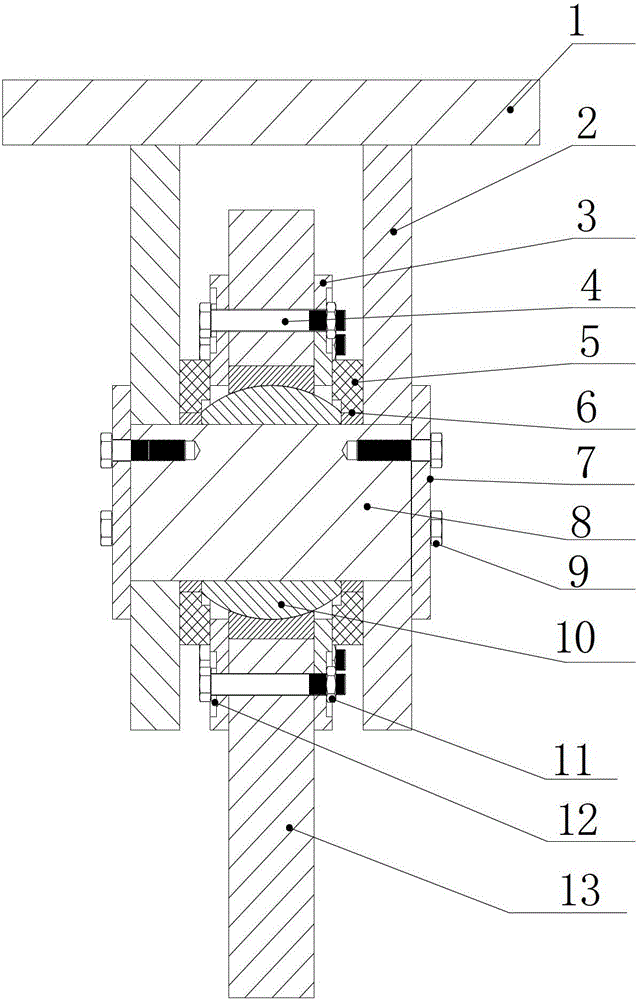

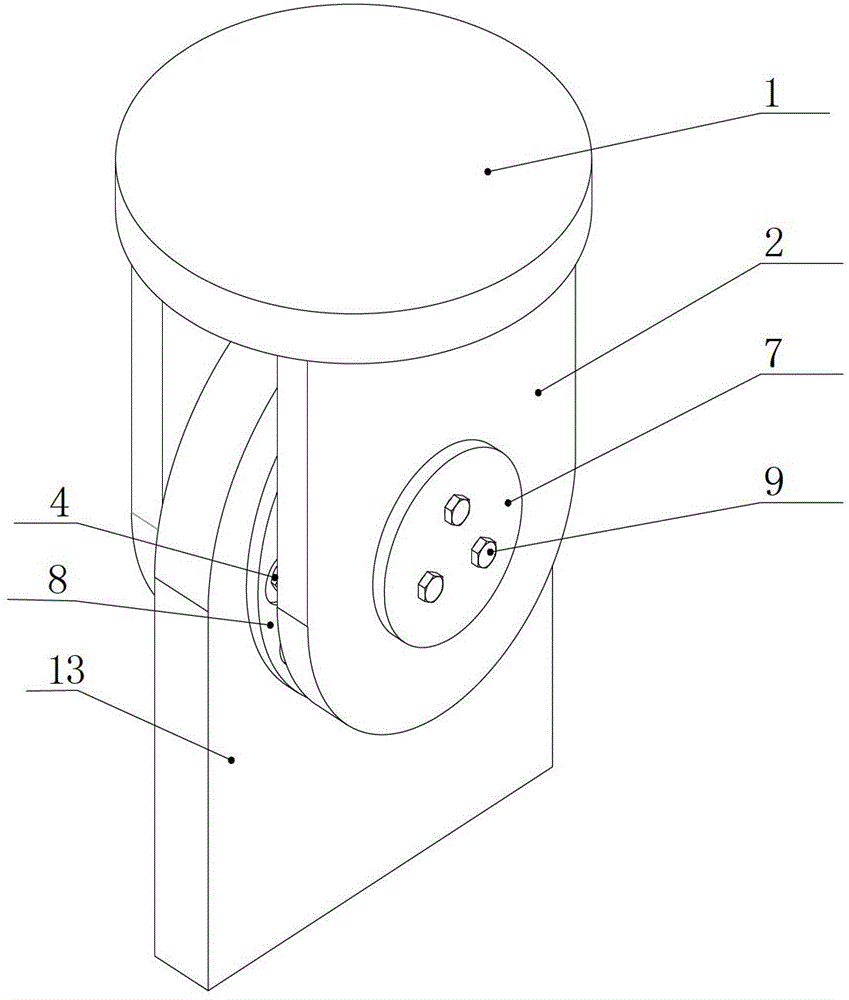

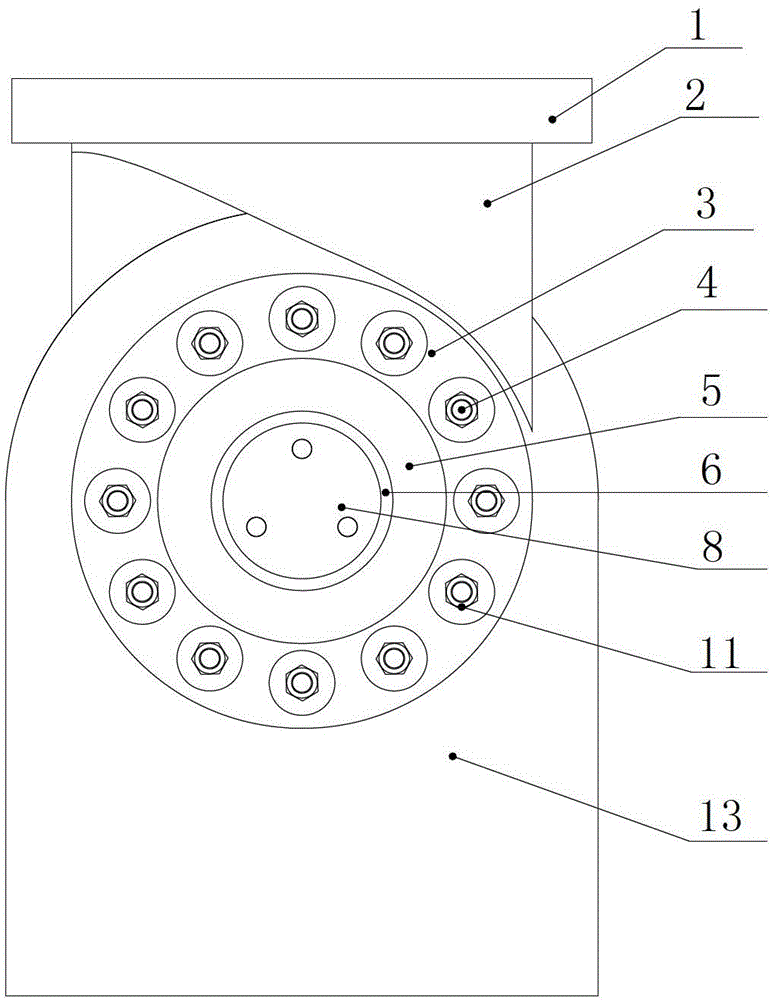

[0017] Such as Figure 1~3 As shown, the embodiment of the present invention is provided with a radial joint bearing 10, a sealing ring 5, a pin shaft 8, a middle ear plate 13, a double ear plate 2, a pin shaft cover plate 7, an annular sticking plate 3, a first bolt 4, a first 2 Bolts 9, nuts 11, spring washers 12 and positioning sleeves 6; the radial joint bearing 10 is provided with an inner ring and an outer ring, the inner ring and the outer ring can rotate and swing relative to each other, and the radial joint bearing 10 is tightly fitted Installed on the bearing hole of the middle ear plate 13, a pair of annular sticking plates 3 press the outer ring of the radial joint bearing 10 and lock it with the first bolt 4, the pin shaft 8 passes through the inner ring of the radial joint bearing 10, and a Set the positioning sleeve 6 into both ends of the pin shaft 8 respectively, and stick to the inner ring end face of the radial spherical plain bearing 10, the sealing ring 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com