Yarn Tension Sensor

A yarn tension and sensor technology, applied in tension measurement, instruments, force/torque/work measuring instruments, etc., to achieve the effect of avoiding measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

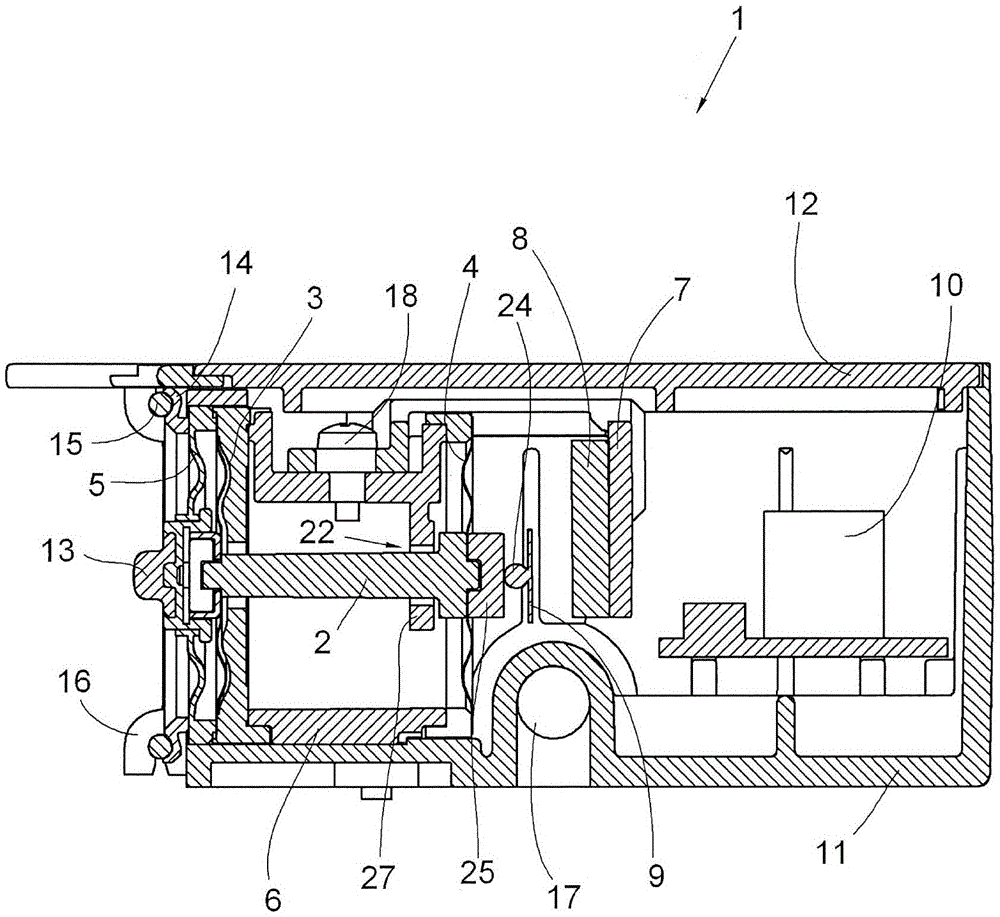

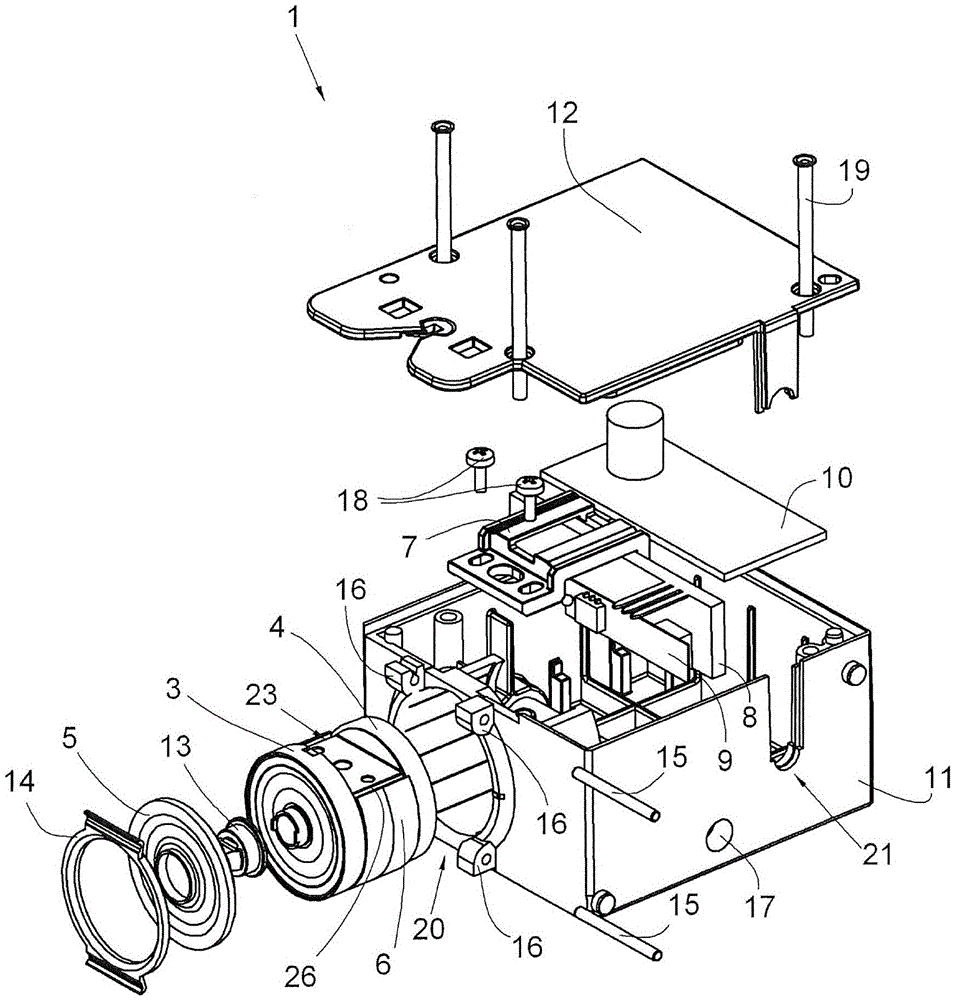

[0022] figure 1 and figure 2 A yarn tension sensor 1 according to the invention is shown for use at a winding machine station. The yarn tension sensor 1 has a housing 11 including a housing cover 12 . The housing cover 12 can be fixedly connected to the housing 11 by means of rivets 19 . The housing has holes 17 . By means of the holes 17 and matching screws, the housing 11 of the yarn tension sensor 1 can be fixed on the support of the winding machine station. Furthermore, the housing 11 has openings 21 for the lead-through of electrical wires. In addition to the components essential to the invention, which will be described in more detail below, evaluation electronics 10 are located in this housing.

[0023] The yarn tension sensor 1 has a rod-shaped force transmission element 2 . The two membranes 3 and 4 act as guides for the force transmission element 2 . These membranes are held by the sleeve 6 and are fixedly coupled thereto. Furthermore, in the region of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com