Capacitive touch panel and production method thereof

A technology of capacitive touch and manufacturing method, which is applied in the direction of electrical digital data processing, instrumentation, input/output process of data processing, etc., and can solve the problems of non-compliance with energy saving and environmental protection, decrease of transmittance of touch screen, large thickness, etc. , to achieve a good appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to illustrate the capacitive touch panel provided by the present invention and the manufacturing method thereof, the present invention will be described in detail below in conjunction with the accompanying drawings.

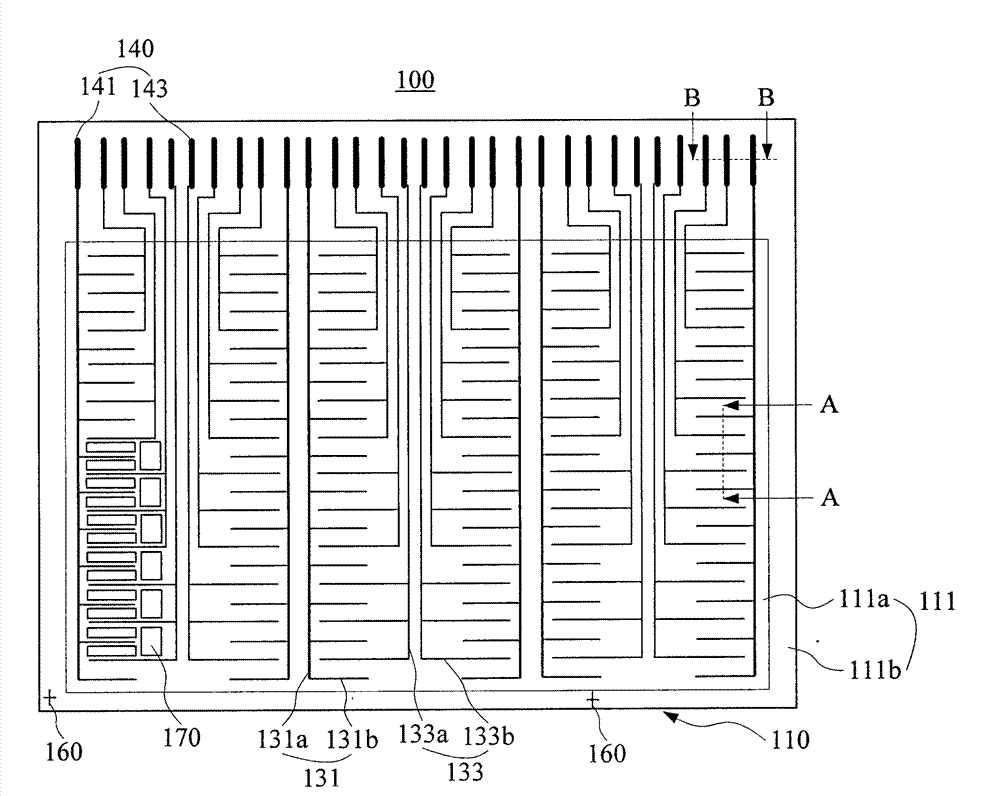

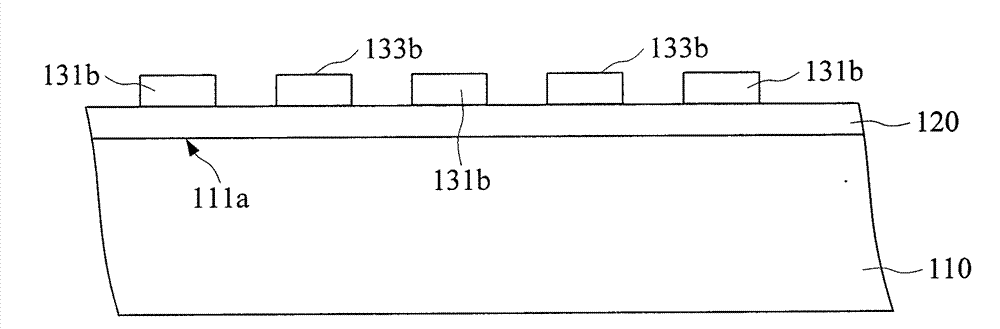

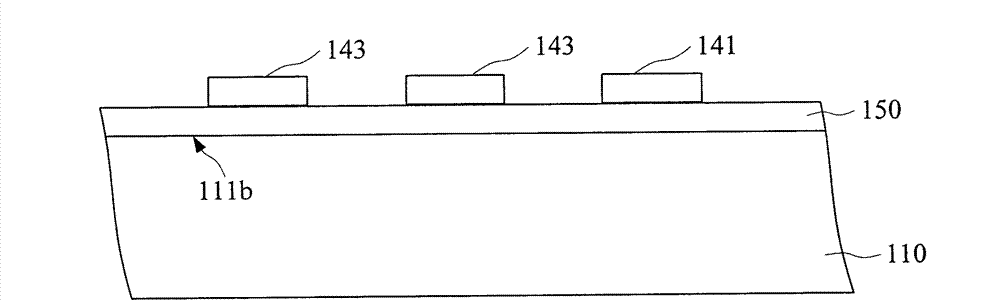

[0024] Please also see figure 1 , figure 2 and image 3 , which is a schematic diagram of a capacitive touch panel according to a preferred embodiment of the present invention, a schematic cross-sectional view of the capacitive touch panel along the direction A-A, and a schematic cross-sectional diagram of the capacitive touch panel along the direction B-B.

[0025] The capacitive touch panel 100 includes a substrate 110 having a first surface 111 . The first surface 111 is a smooth plane, which includes a first region 111a and a second region 111b, and the first region 111a is adjacent to the second region 111b. In this embodiment, the first area 111a is rectangular, and the second area 111b is a rectangular ring surrounding the first area 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com