Automatic paint spraying device of inner wall

A technology of automatic spray painting and automatic spray gun, applied in the direction of spray device, etc., can solve the problems of limited activity space for workers, difficult manual spray operation, uneven thickness of paint film, etc., to reduce labor intensity of workers, improve workers' working environment, and paint thickness uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

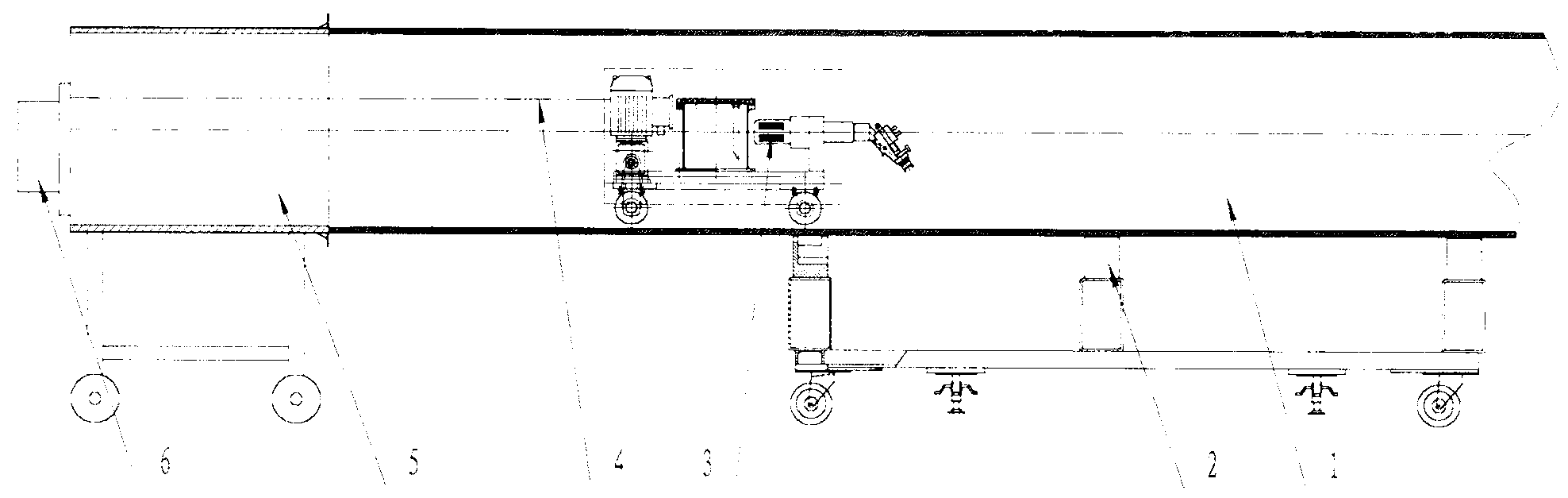

[0022] Such as figure 1 As shown, the automatic paint spraying device for the inner wall of the present invention is composed of the following parts: a metal pipe parking trolley 2, a spraying trolley 3, an umbilical cable 4, a spraying trolley guiding trolley 5, and an electrical control cabinet 6.

[0023] 1. Metal tube parking frame car 2

[0024] The metal pipe parking spray rack cart 2 is used to place the metal pipe product 1 when spraying the inner wall.

[0025] 2. Spraying trolley 3

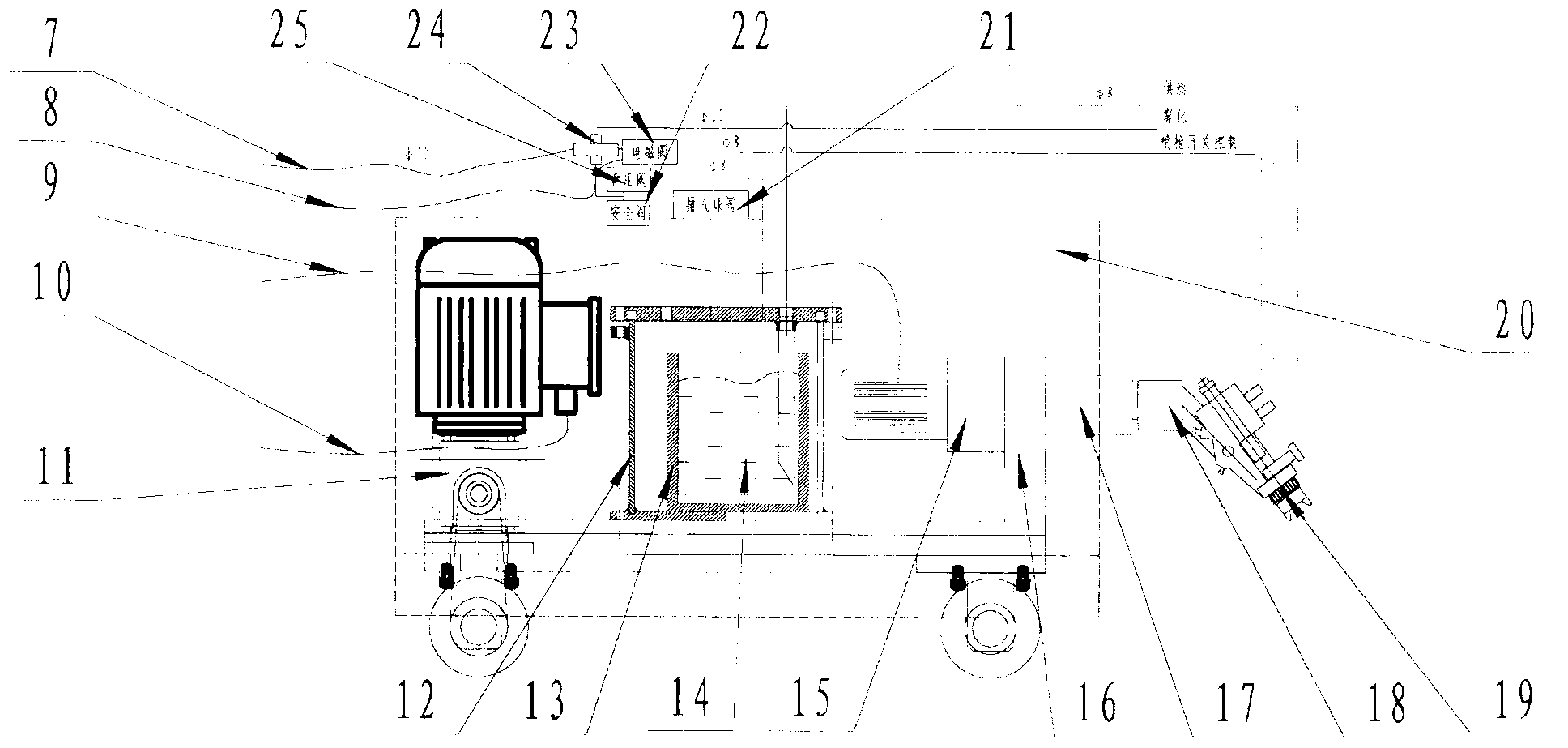

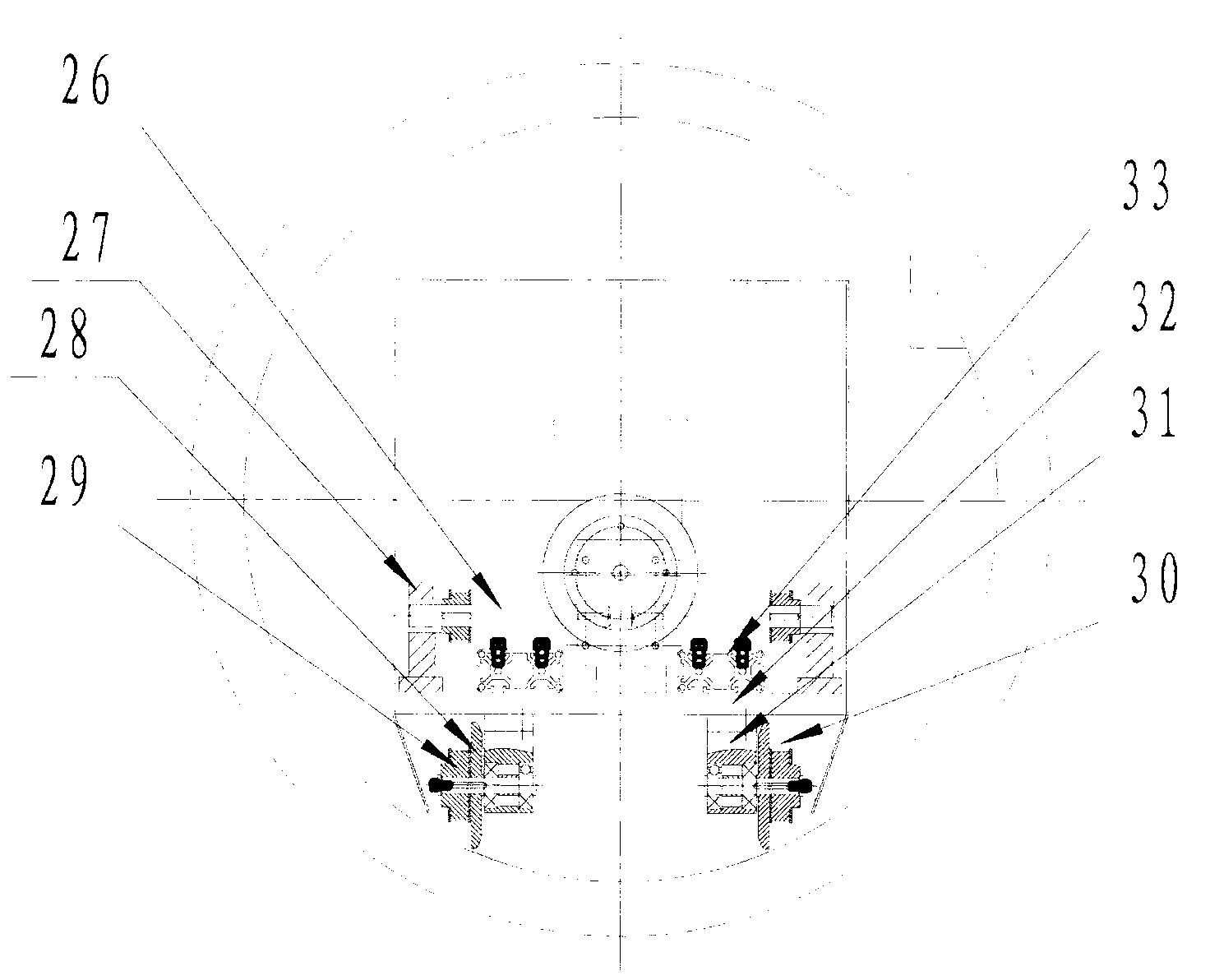

[0026] The spraying car is composed of the following parts: chassis, driving system, painting system, pneumatic control system, protective cover, etc. All components are connected by bolts.

[0027] system diagram see figure 1 , figure 2 , image 3 .

[0028] (1) Chassis

[0029] The chassis is the installation platform for the walking drive system, painting system, pneumatic control system and protective cover of the spraying trolley. It is composed of light materials such as a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap