High-speed five-degree of freedom parallel manipulator

A degree of freedom, manipulator technology, applied in the field of robotics, can solve problems such as the lack of research on space five-degree-of-freedom parallel mechanisms, and achieve the effects of small mass, good dynamic performance, and symmetrical mechanism structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in combination with specific embodiments.

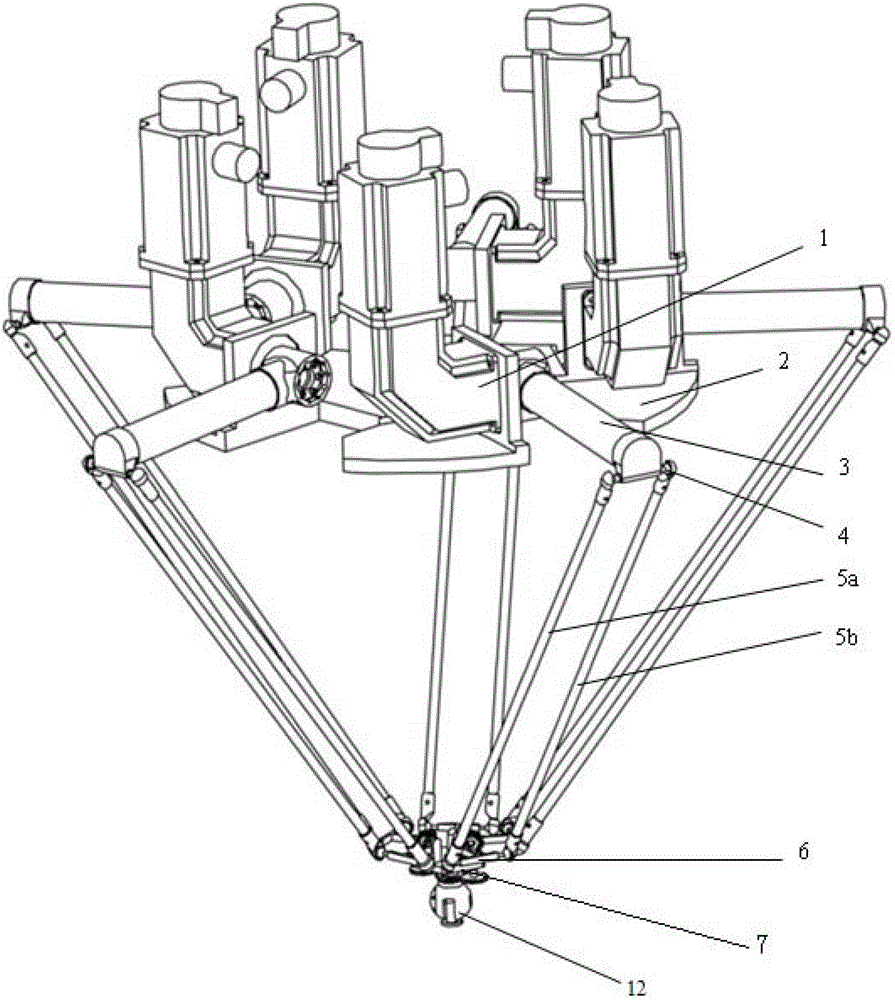

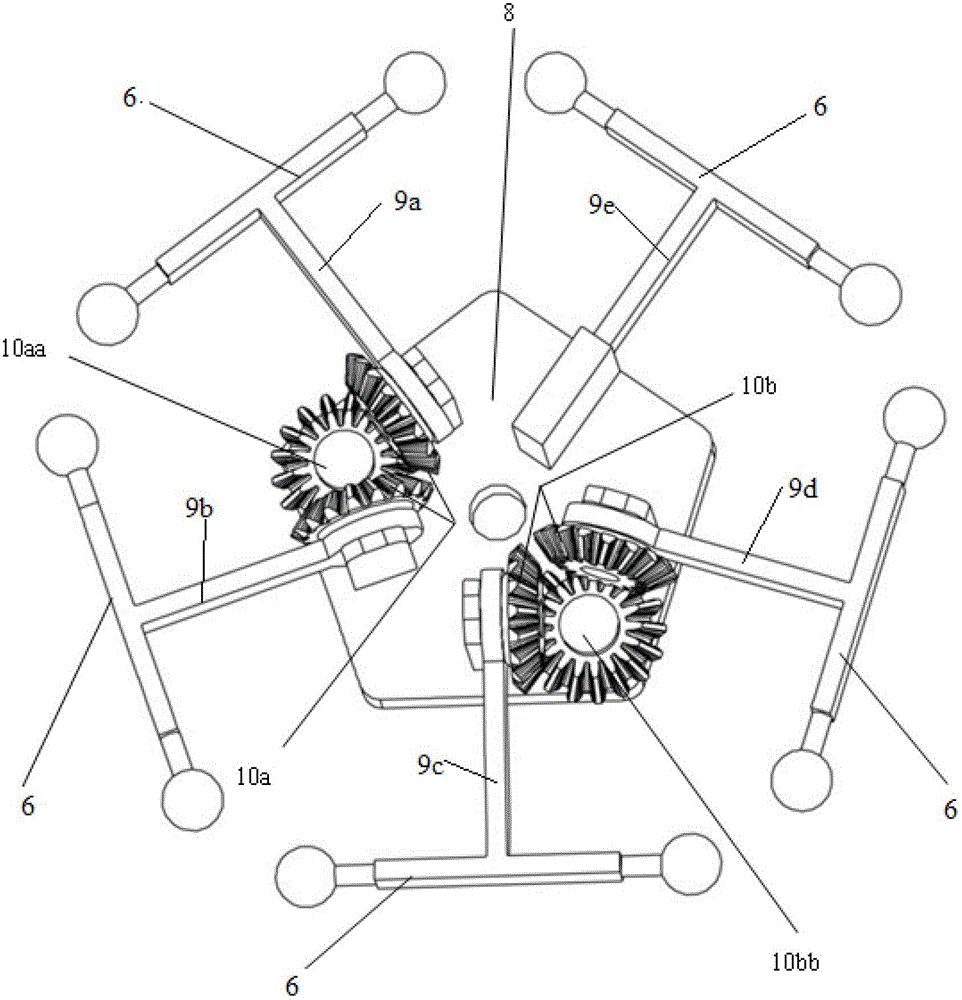

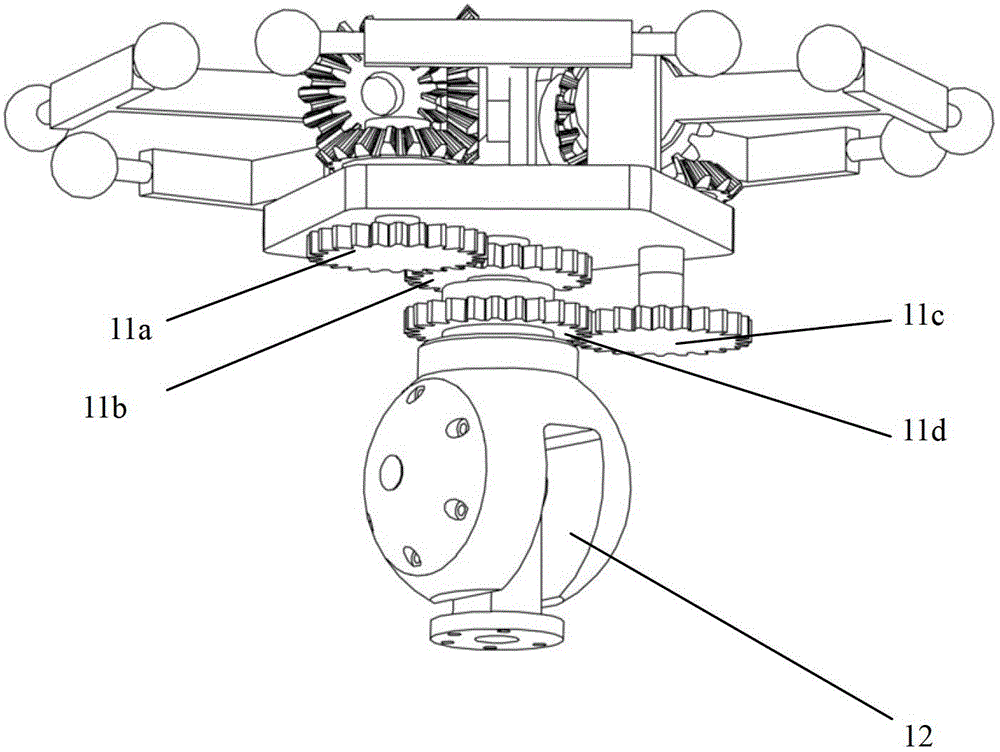

[0017] Such as figure 1 As shown, a five-degree-of-freedom parallel manipulator of the present invention includes a fixed frame 2, a moving platform 7, a two-degree-of-freedom wrist 12, and five branch chains with the same structure arranged between the fixed frame 2 and the moving platform 7.

[0018] Five driving devices 1 are affixed to the fixed frame 2; each branch chain includes a near-frame rod 3, an upper connecting shaft 4, two parallel and equal-length far-mounting rods 5a, 5b and a lower connecting shaft 6.

[0019] In each branch chain, one end of the near frame bar 3 is fixedly connected to the output end of a drive device 1 fixed on the fixed frame 2, and the drive device 1 provides a degree of freedom for the near frame bar 3 to rotate or move The other end of the near frame rod 3 is fixedly connected with the upper connecting shaft 4; one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com