A compound braking system and method for a coke oven electric locomotive

A compound braking and electric locomotive technology, applied in the railway braking system, etc., can solve the problems of soft braking force, one-sided braking function, and long braking time, so as to reduce complex structures, facilitate control and use, The effect of high braking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention provides a coke oven electric locomotive compound braking system and method, and the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

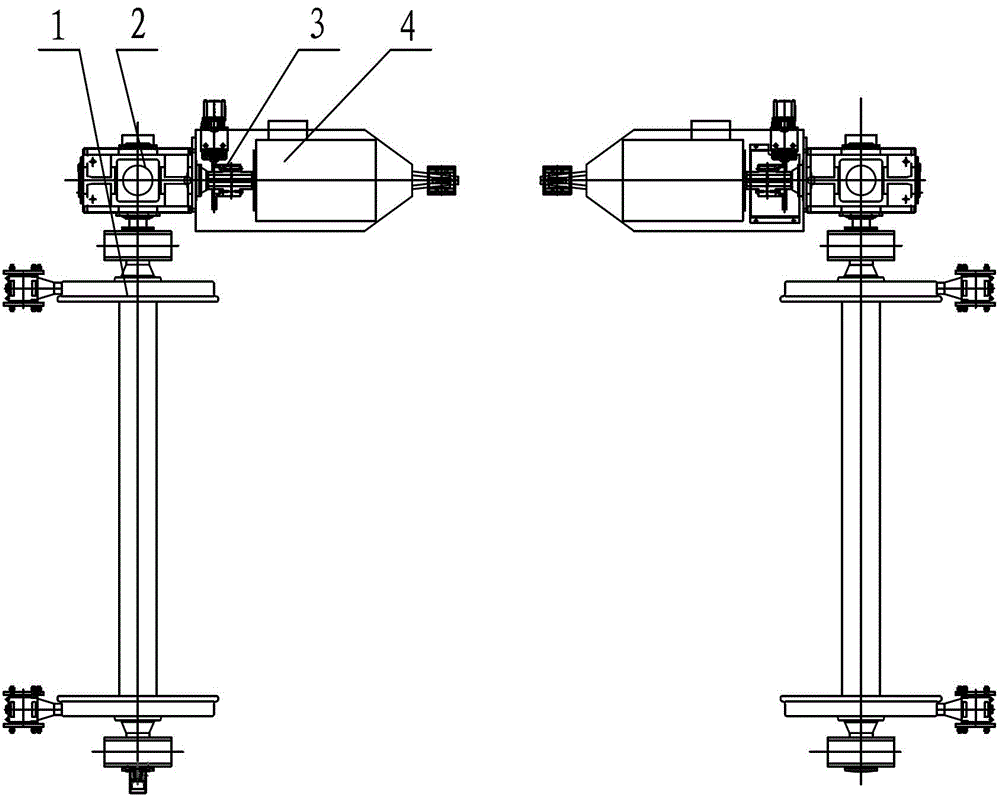

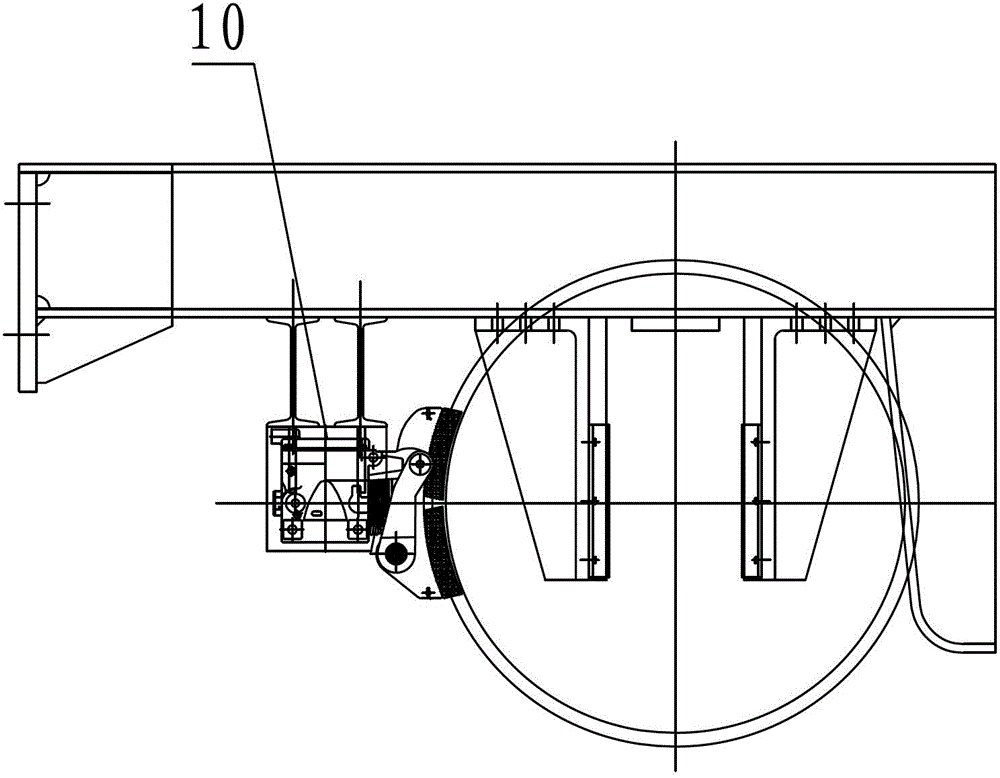

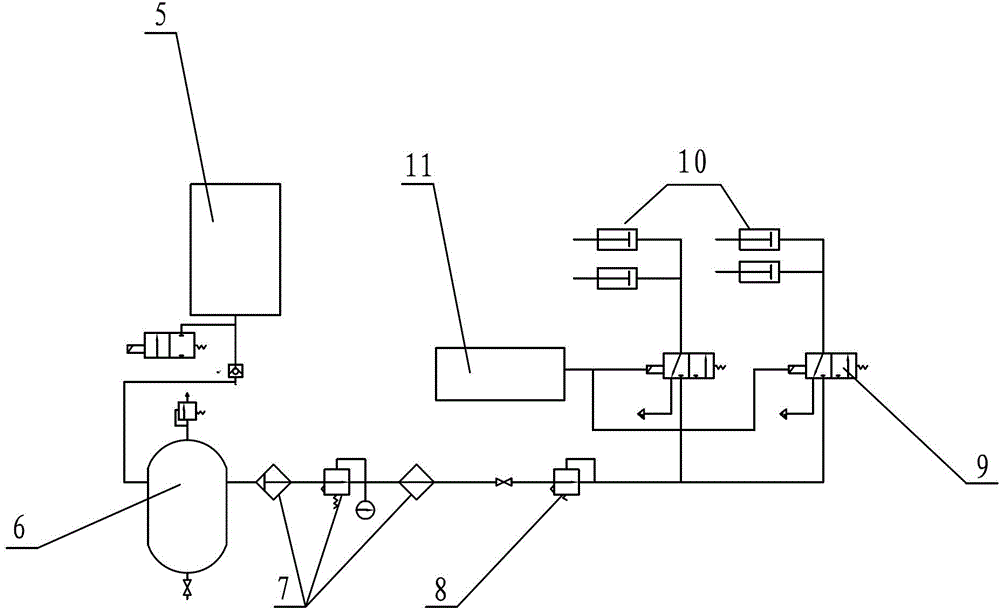

[0027] figure 1 It is a structural schematic diagram of an embodiment of the present invention in which the electromagnetic disc brake is arranged; figure 2 It is an enlarged structural view of an embodiment of the present invention where the brake shoe of the pneumatic unit is arranged; image 3 It is an air circuit system diagram of an embodiment of the pneumatic unit brake shoe brake of the present invention; Figure 4 It is a front view of an embodiment of the coke oven electric locomotive compound braking system of the present invention, as shown in the figure.

[0028] Coke oven electric locomotive compound brake system includes wheel set 1, reducer 2, electromagnetic disc brake 3, motor 4, air compressor 5, air bag 6, pneumatic tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com