Full frame tank type container

A tank container and frame technology, applied in the field of full-frame tank containers, can solve the problems of cost reduction, different front and rear frame structures, complex and cumbersome process processing, etc., and achieve convenient and fast installation and maintenance, large bottom unloading space, The effect of structural safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

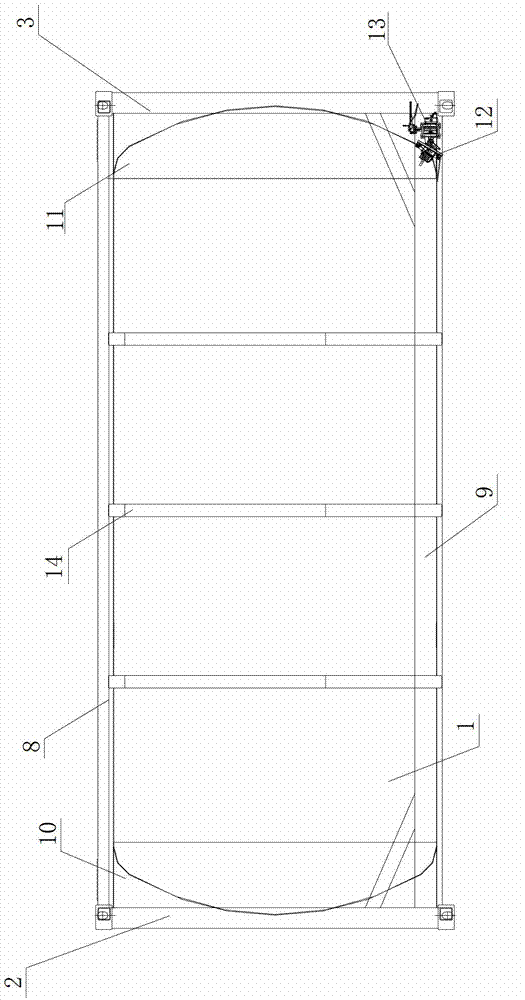

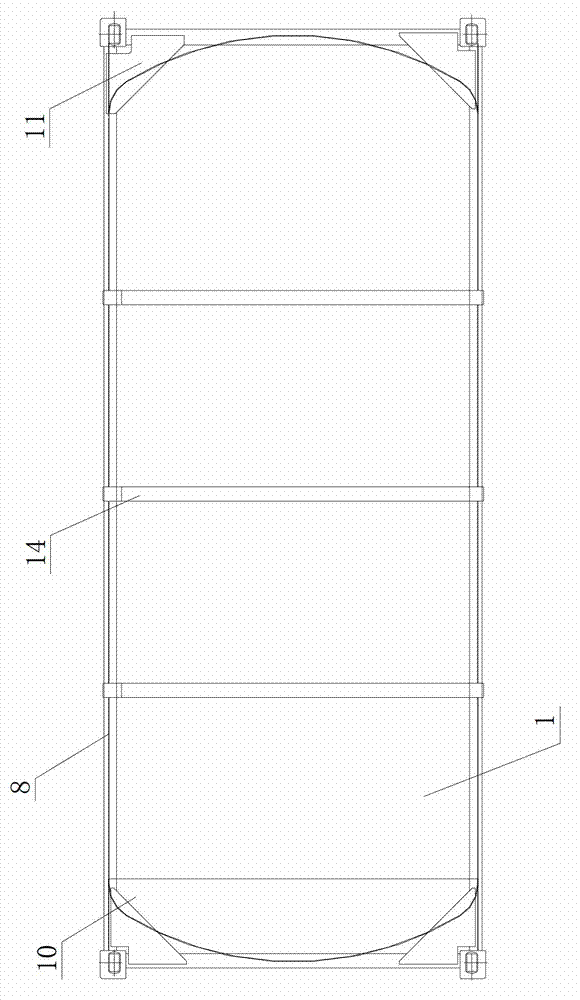

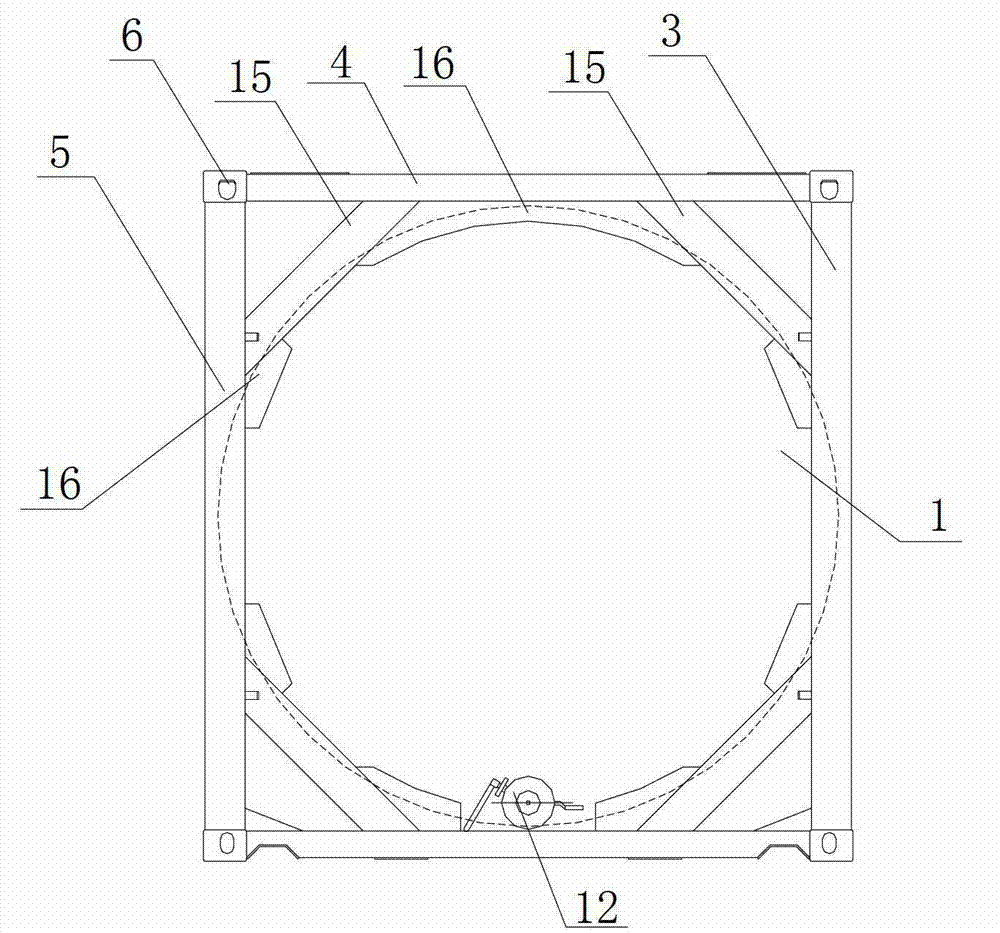

[0020] see Figure 1 to Figure 4 , a full-frame tank container, comprising a tank body 1, a front frame 2 and a rear frame 3 of the same structure located at the front and back of the tank body respectively, the front and rear frames are respectively composed of two beams 4, two columns 5, two roofs The corner fittings 6 and two bottom corner fittings 7 are welded. The front and rear frames are connected to the front and rear frames (2, 3) through the upper and lower side beams (8, 9), and the tank body 1 is connected to the front and rear skirts (10, 3). 11) Connected with the front and rear frames, the bottom of the rear side of the tank is provided with a bottom discharge system 12, the bottom discharge system 12 is provided with an inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com