Quicklime slaking system

A digestion system and quicklime technology, which is applied in the field of flue gas desulfurization, can solve the problems of inability to meet the requirements of fluffy dry powder and insufficient digestion of quicklime, and achieve the effects of adapting to environmental protection requirements, avoiding clogging and no dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

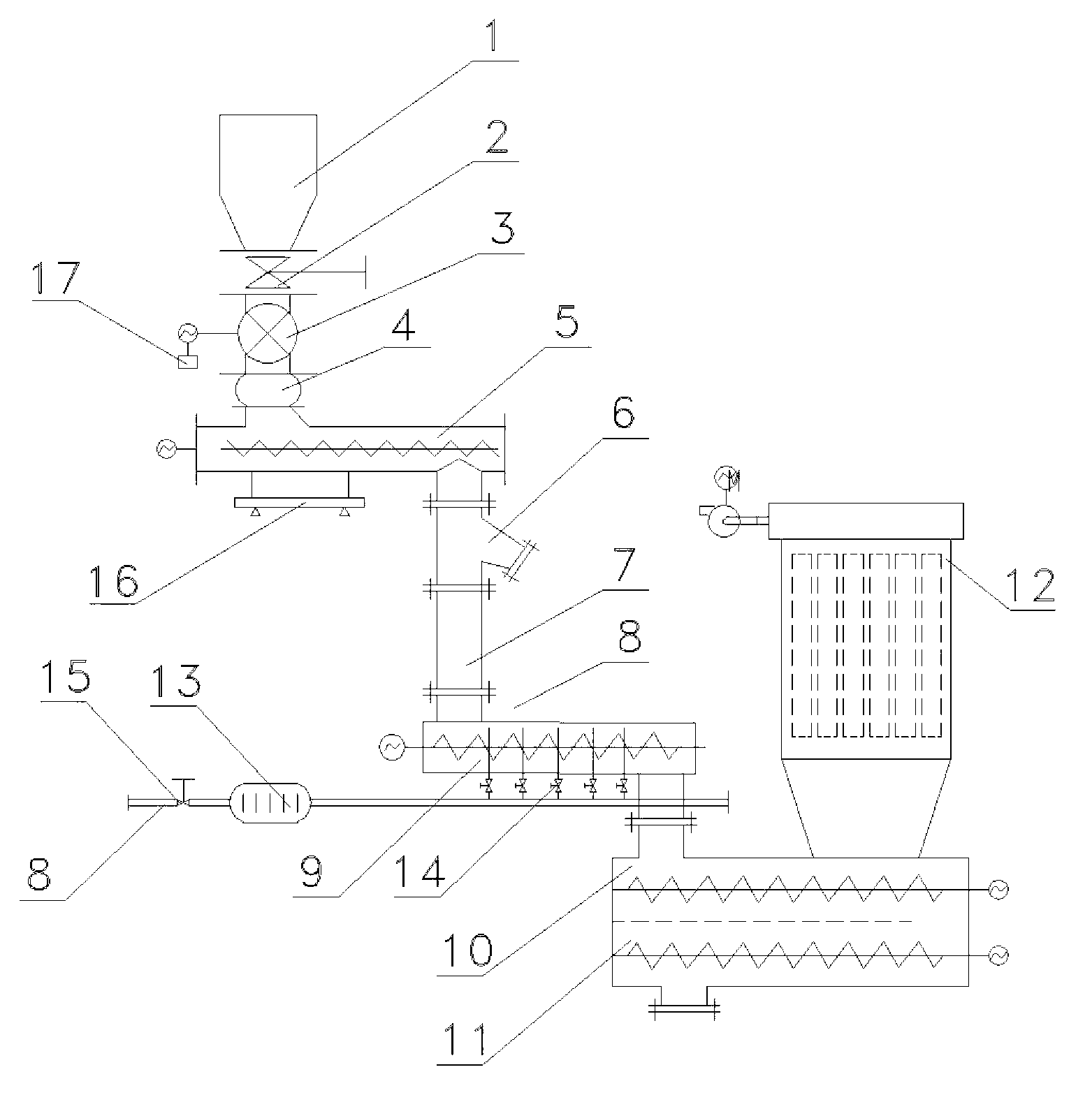

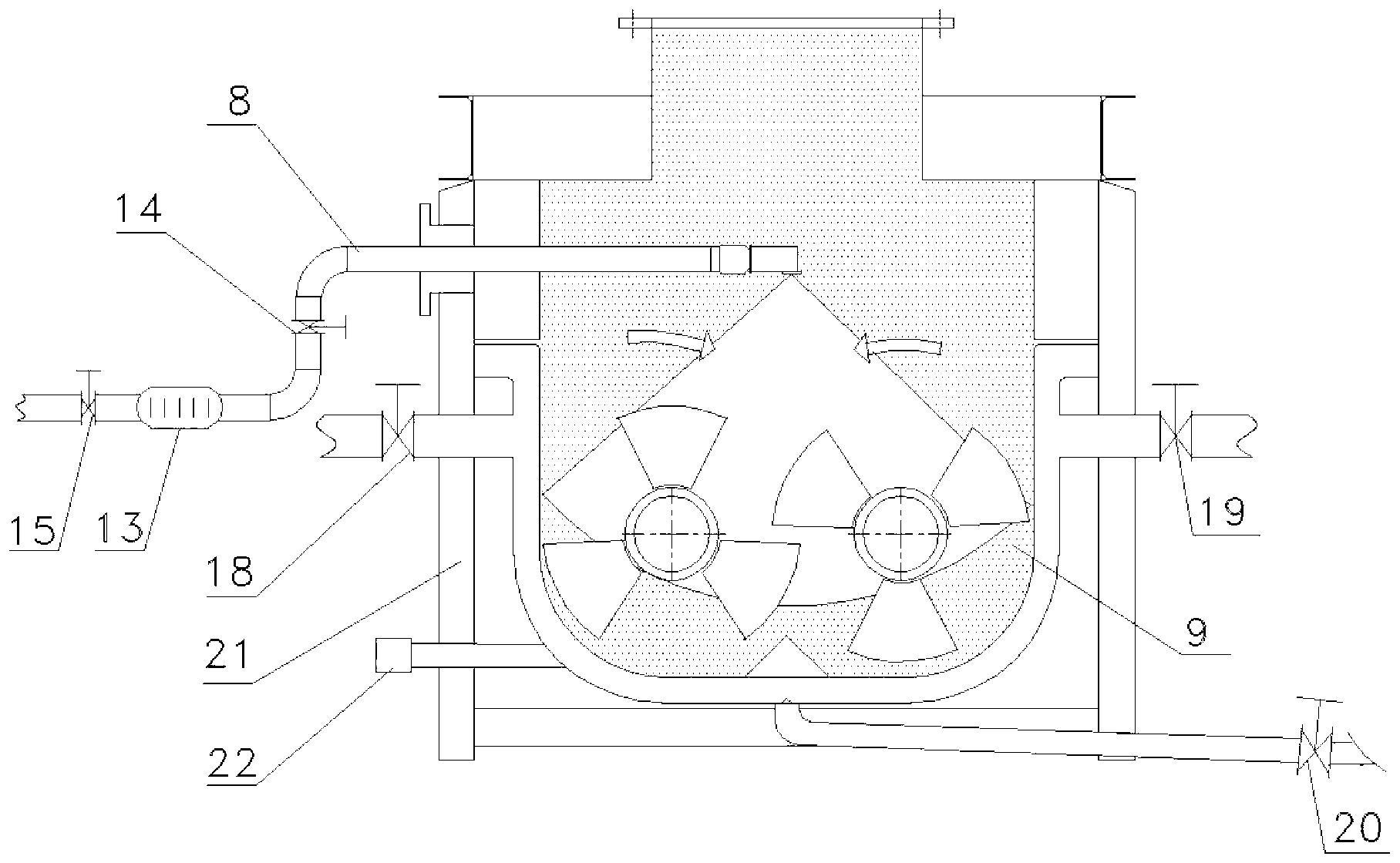

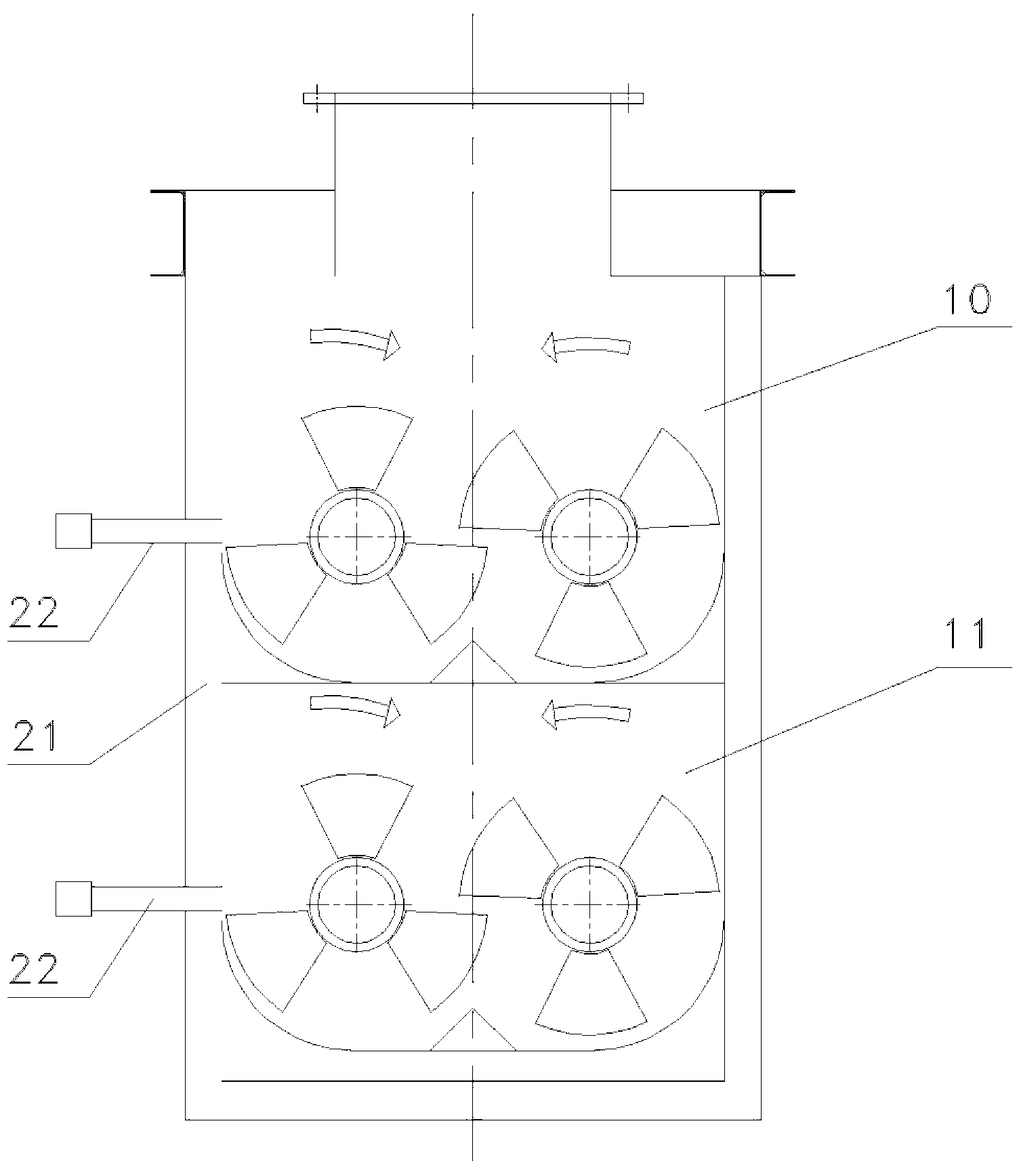

[0029] The present invention will be further described below in conjunction with accompanying drawing.

[0030] Such as figure 1 , 2 , Shown in 3, a quicklime digestion system includes a hopper 1, an inspection door 2, a feeder 3, a screw conveyor 5, and a primary digester 9, and the inspection door 2 is normally open, and is closed when the system fails. The feeder 3 is set under the hopper 1 through the inspection door 2, the screw conveyor 5 is connected under the feeder 3, the first-stage digester 9 is connected to the lower end of the screw conveyor 5, and the one A water inlet pipe 8 is provided on the first-stage digester 9, and a water supply valve 15, a flow meter 13 and a flow regulating valve 14 are arranged in sequence on the water inlet pipe 8, which can be adjusted according to the actual amount of quicklime and the moisture content of the final product slaked lime. Water volume; the function of the flowmeter 13 is to accurately measure the actual water supply....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com