Internal plasticization artware molding emulsion as well as preparation method and use thereof

A handicraft and internal plasticizing technology, applied in the field of internally plasticized handicraft plastic emulsion and its preparation, can solve the problems of brittleness, fuzzy molding lines, hard film formation, etc., and achieve obvious relief effect, clear molding texture, Body without blemish effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of plasticized handicraft molding emulsion in the present invention is:

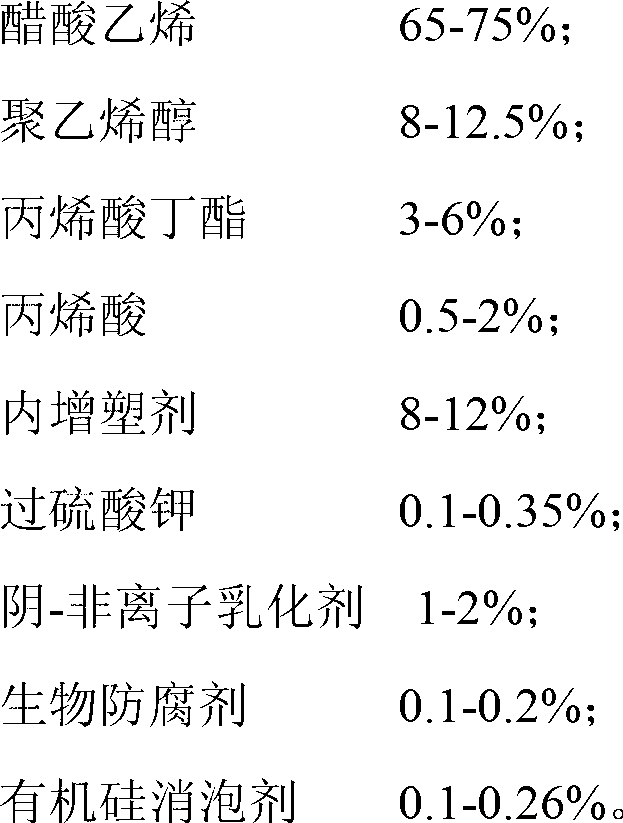

[0036] 1) First weigh each solid component according to the formula:

[0037]

[0038] Potassium persulfate is configured to a concentration of 5% aqueous solution;

[0039] The anion-nonionic emulsifier is polyoxyethylene ether nonylphenol disodium sulfosuccinate.

[0040] The internal plasticizer is a mixture of dibutyl phthalate and dioctyl phthalate in a mass ratio of 1:1.

[0041] 2) Preparation of protective colloid: put deionized water into the reaction kettle, start the mixer, put in polyvinyl alcohol, the weight ratio of polyvinyl alcohol to deionized water is 1:9, then slowly heat up to 85-95°C, keep warm After 1 hour, cool down to 65-70°C to obtain the protective colloid;

[0042] 3) Preparation of pre-emulsion: inject deionized water into the head tank, start the mixer, and then put in the anion-nonionic emulsifier, the weight ratio of the anion-nonionic em...

Embodiment 2

[0047] The preparation method of plasticized handicraft molding emulsion in the present invention is:

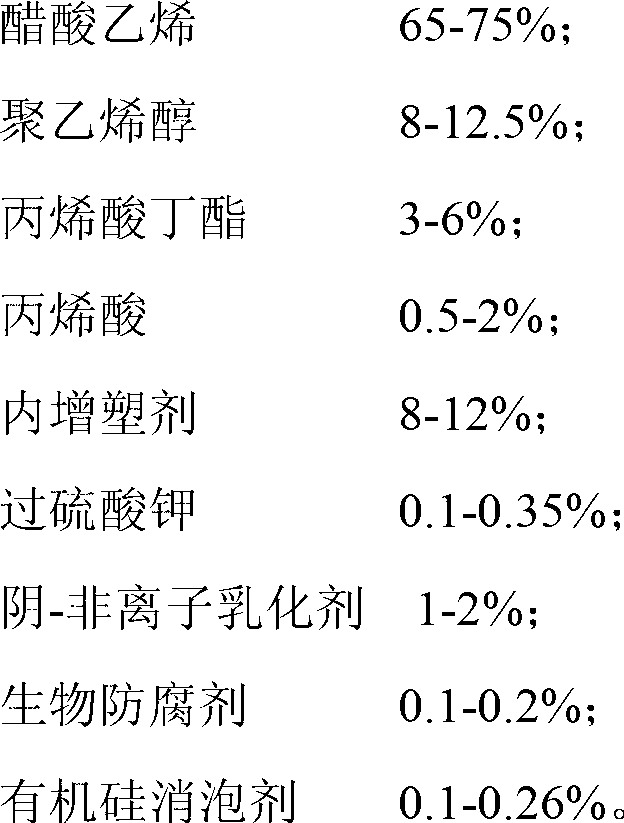

[0048] 1) First weigh each solid component according to the formula:

[0049]

[0050] Potassium persulfate is configured into a concentration of 10% aqueous solution;

[0051] The anion-nonionic emulsifier is a mixture of disodium ethoxy alcohol sulfosuccinate and nonylphenol polyoxyethylene ether in a mass ratio of 1:2.

[0052] The internal plasticizer is dibutyl maleate.

[0053] 2) Preparation of protective colloid: put deionized water into the reaction kettle, start the mixer, put in polyvinyl alcohol, the weight ratio of polyvinyl alcohol to deionized water is 1:9, then slowly heat up to 85-95°C, keep warm After 1.2 hours, cool down to 65-70°C to obtain the protective colloid;

[0054] 3) Preparation of pre-emulsion: inject deionized water into the head tank, start the mixer, and then put in the anion-nonionic emulsifier, the weight ratio of the anion-nonionic e...

Embodiment 3

[0059] The preparation method of plasticized handicraft molding emulsion in the present invention is:

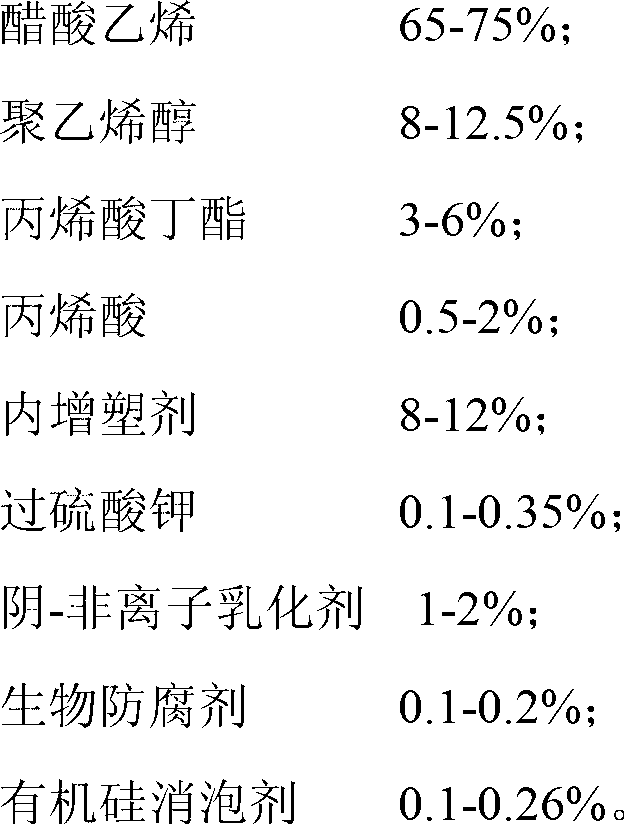

[0060] 1) First weigh each solid component according to the formula:

[0061]

[0062]

[0063] Potassium persulfate is configured into a concentration of 8% aqueous solution;

[0064] The anion-nonionic emulsifier is polyoxyethylene ether nonylphenol disodium sulfosuccinate.

[0065] The internal plasticizer is soybean epoxy ester.

[0066] 2) Preparation of protective colloid: put deionized water into the reaction kettle, start the mixer, put in polyvinyl alcohol, the weight ratio of polyvinyl alcohol to deionized water is 1:9, then slowly heat up to 85-95°C, keep warm After 1.5 hours, cool down to 65-70°C to obtain the protective colloid;

[0067] 3) Preparation of pre-emulsion: inject deionized water into the head tank, start the mixer, and then put in the anion-nonionic emulsifier, the weight ratio of the anion-nonionic emulsifier to deionized water is 1:8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com