I/O hole detecting machine platform

A technology of machine and detection device, which is applied in measurement devices, instruments, and optical devices, etc., can solve problems such as lower detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

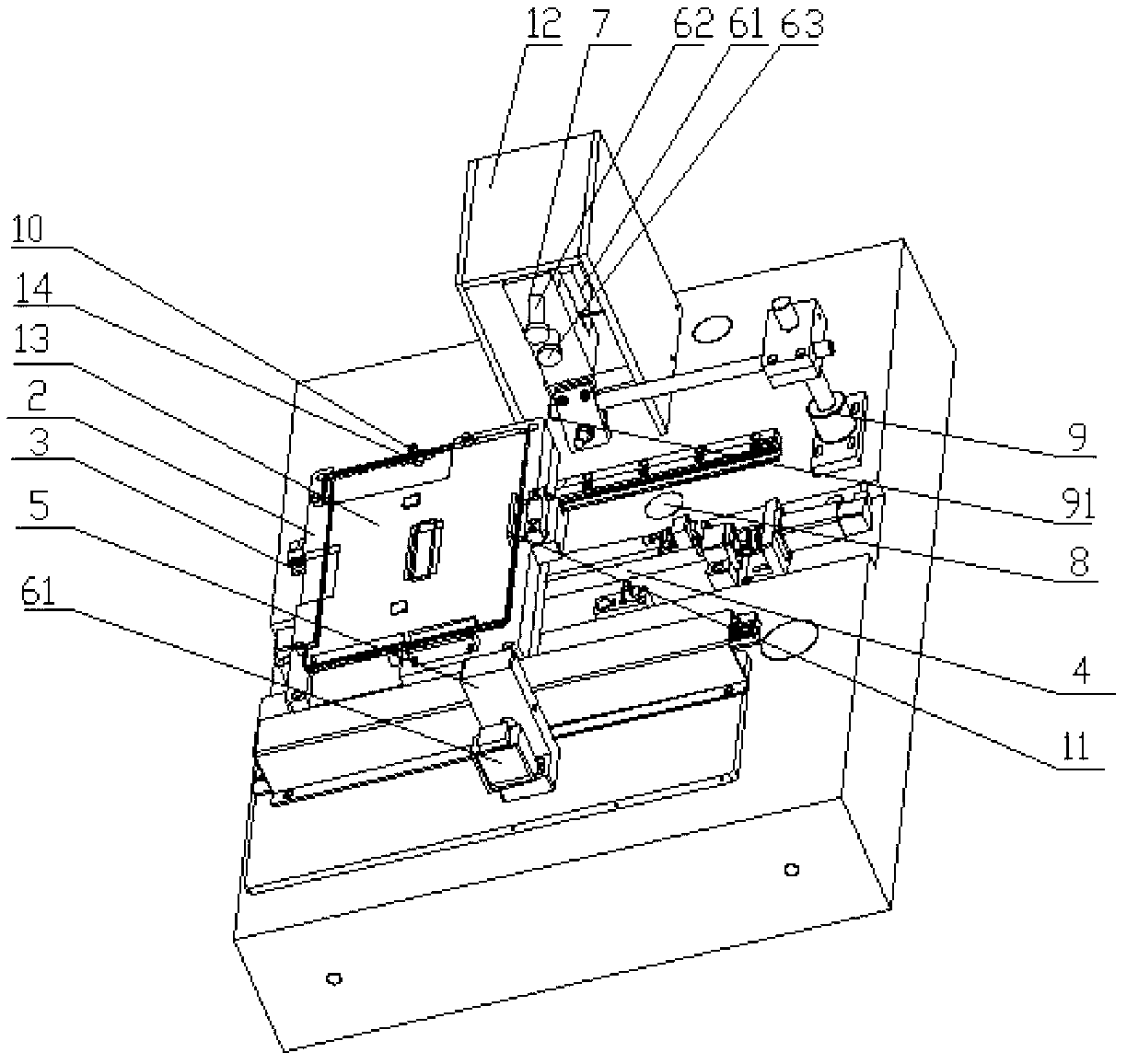

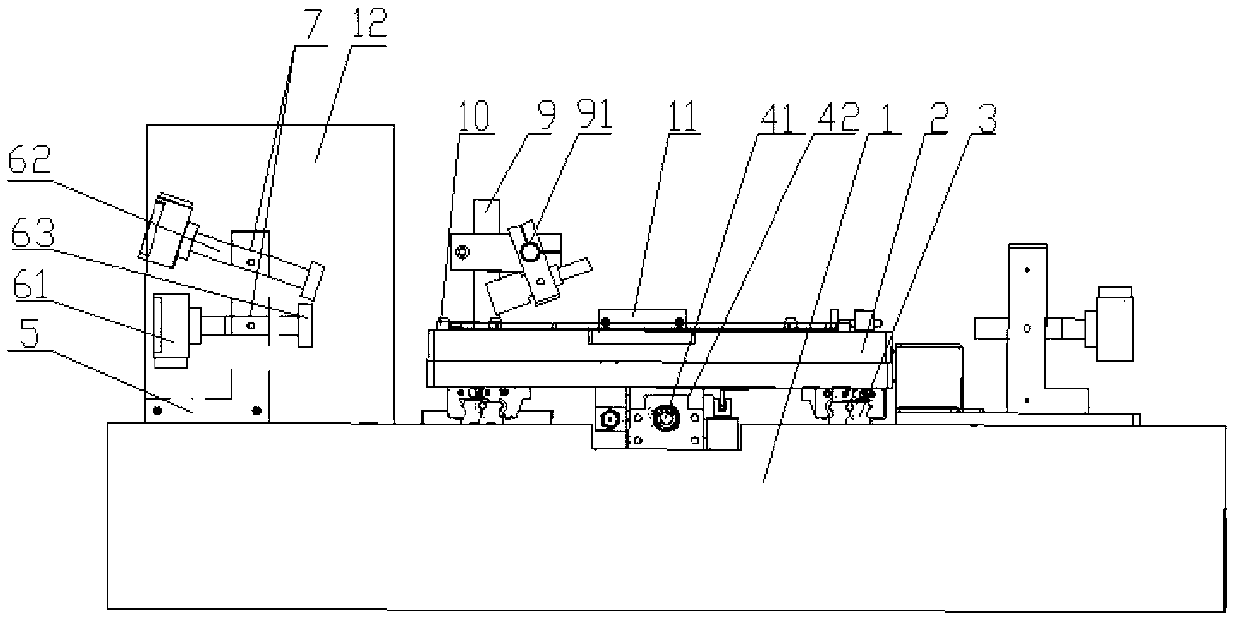

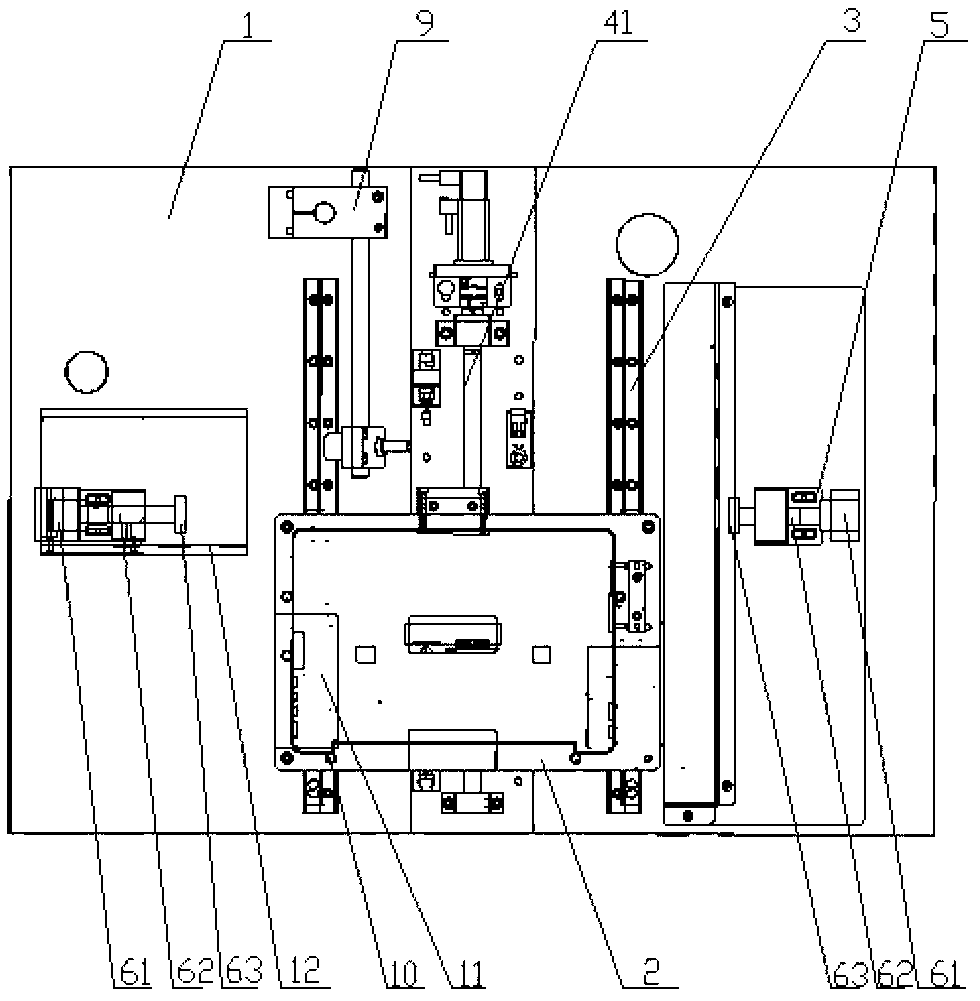

[0019] figure 1 The shown I / O hole detection machine includes a base 1, a workbench 2, a guide rail 3, a screw 41, a movable nut 42, an L-shaped support 5, a CCD imaging device 61, a lens 62, a light source 63, and a positioning hole 7. Active light source 8, support 9, light source 91, positioning pin 10, pressing device 11, protective cover 12, product 13 and reference hole 14.

[0020] figure 2 , image 3 with Figure 4 The shown I / O hole detection machine mainly includes a base 1, a workbench 2, a screw 41 and related linkage structures and detection devices. The workbench 2 is placed on the base 1 through a screw mechanism, and the lead screw 41 and The related linkage mechanism consists of two guide rails 3 arranged in parallel on the base, a lead screw 41, a motor, a control program, and a movable nut 42 fixedly connected to the workbench. The relative position of the table. The two detection devices are arranged on the same straight line outside the two parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com