Adjusting Mechanism of Aeroengine Air Belt Rotation Tester

A technology of aero-engine and adjustment mechanism, which is applied in the direction of engine testing, machine/structural component testing, instruments, etc. It can solve problems such as undeveloped technology and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

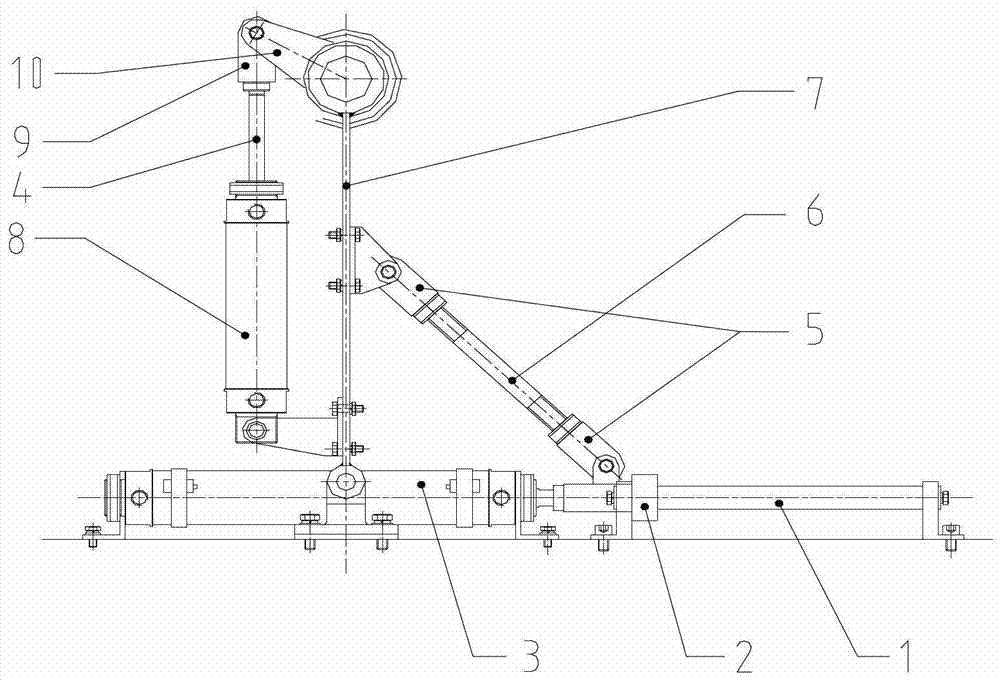

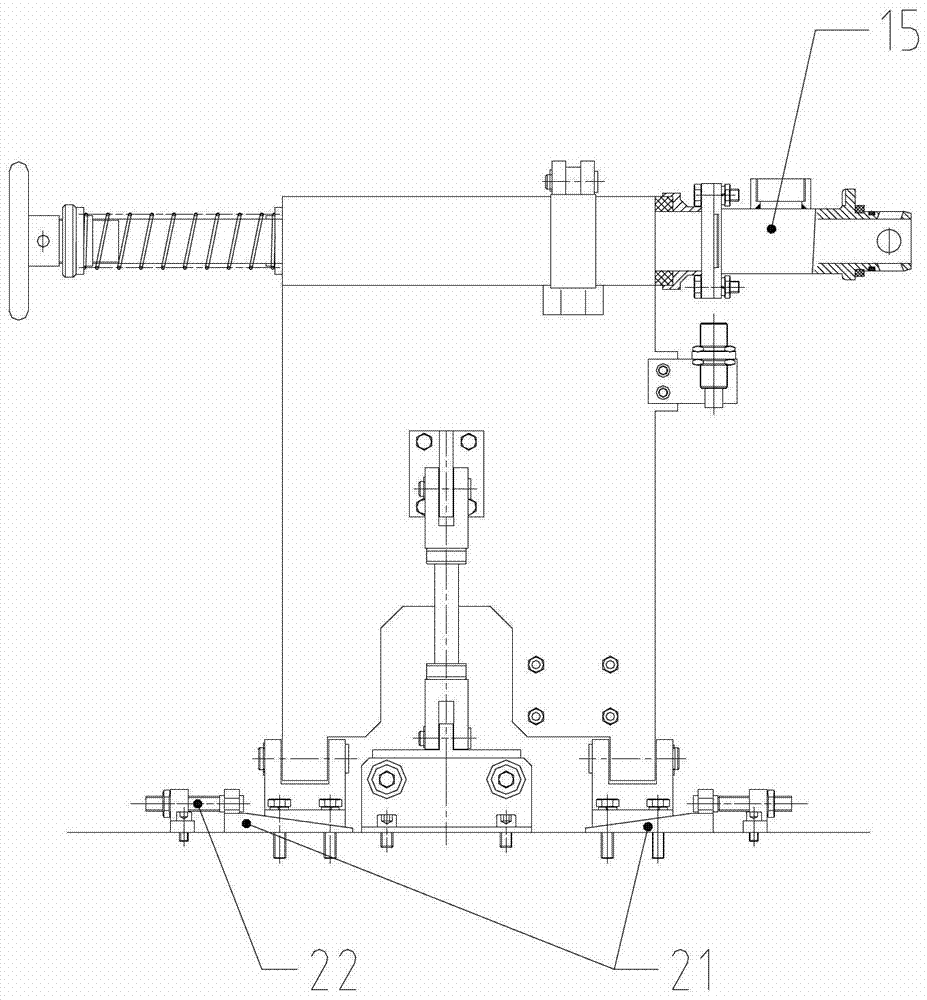

[0009] As shown in the figure, the adjustment mechanism of the aero-engine air belt rotation tester includes a main support frame 7, a slider 2 that is connected to the piston of the feed cylinder 3 and can slide on the guide rod 1, and is connected to the main support frame 7 through the hinge ear 5. The pull rod 6 hinged with the slide block 2, the locking cylinder 8 hingedly installed on the main support frame 7, the two oblique irons 21 placed below the main support frame 7, the main support frame 7 is provided with an air supply gun head 15, so The above two hinge ears 5 are provided with threads with opposite rotation directions, the pull rod 6 is fitted between the two hinge ears 5, the piston of the locking cylinder 8 is equipped with a pull rod 4, and the pull rod 4 passes through The thread is connected with the hinge ear 9, and the hinge ear 9 is hinged with the support arm 10 provided on the shaft sleeve of the air supply gun head. The positions of the two oblique i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com