Two-dimensional transmissive fast reflecting mirror

A transmissive and reflective mirror technology, which is applied in the control, installation, and optics of using feedback, can solve the problem of not being able to drive the beam combiner to combine and align the laser beam accurately, so as to increase the shear resistance and facilitate implementation , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

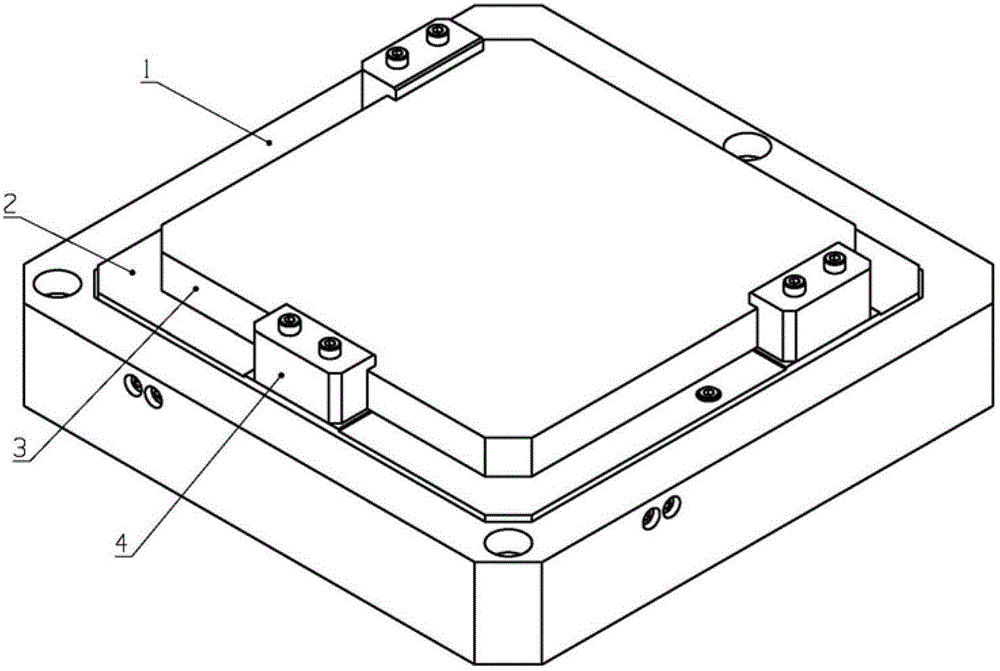

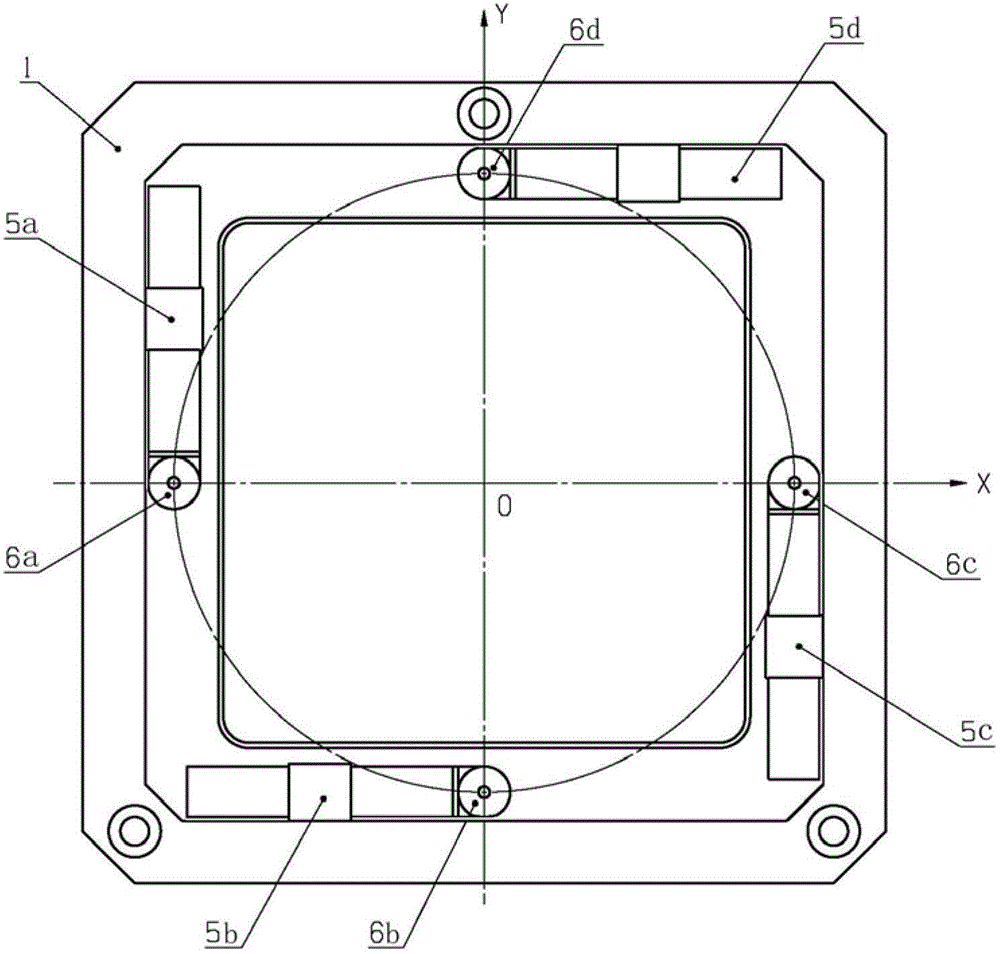

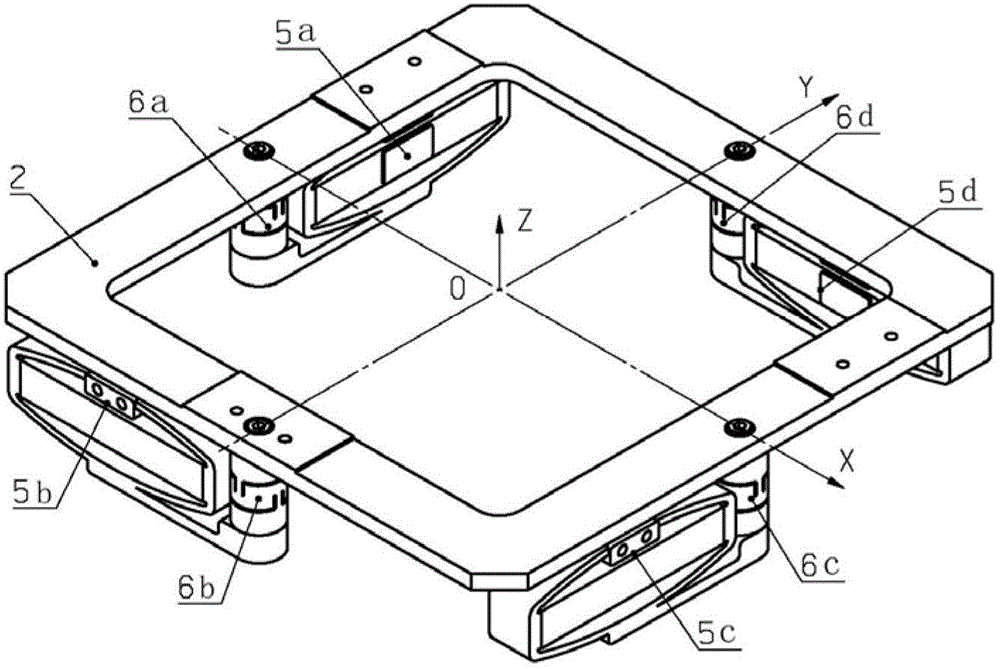

[0024] refer to Figure 1-7 , the two-dimensional transmissive fast reflection mirror of the present invention includes: a support base 1, a mirror body support plate 2, a beam combining mirror 3, a mirror body pressing block 4, a first driver assembly 5a, a first flexible hinge 6a, a second driver Assembly 5b, second flexible hinge 6b, third actuator assembly 5c, third flexible hinge 6c, fourth actuator assembly 5d, fourth flexible hinge 6d. Wherein, the driver assembly 5 is composed of three parts: an oval elastic outer frame 51 , a piezoelectric ceramic 52 and a resistance strain gauge 53 . The piezoelectric ceramic 52 is embedded in the elliptical elastic outer frame 51 through the pre-tightening force, and the resistance strain gauge 53 is bonded to the outside of the piezoelectric ceramic 52 for indirect measurement of the expansion and contraction length of the piezoelectric ceramic 52 . Static support holes 511 and movable support holes 512 are distributed on the oval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com