Nozzle mechanism

A nozzle and rotary chamber technology, applied in the direction of injection device, injection device, liquid injection device, etc., can solve the problems of turbulent flow, large resistance, reduced flow rate of content, etc., to achieve less spray volume, increased rotation speed, and small nozzle diameter. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

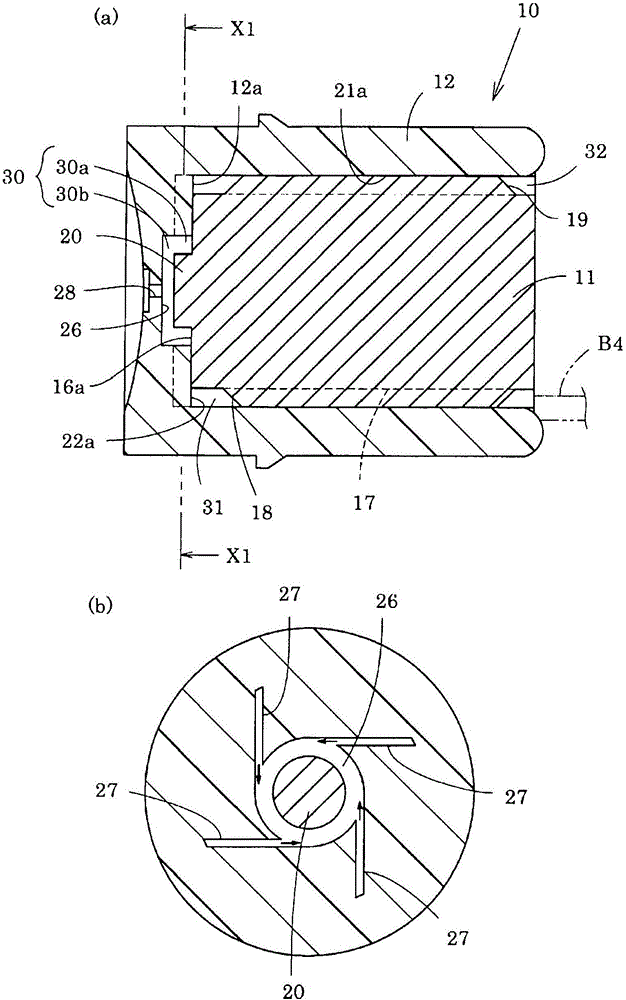

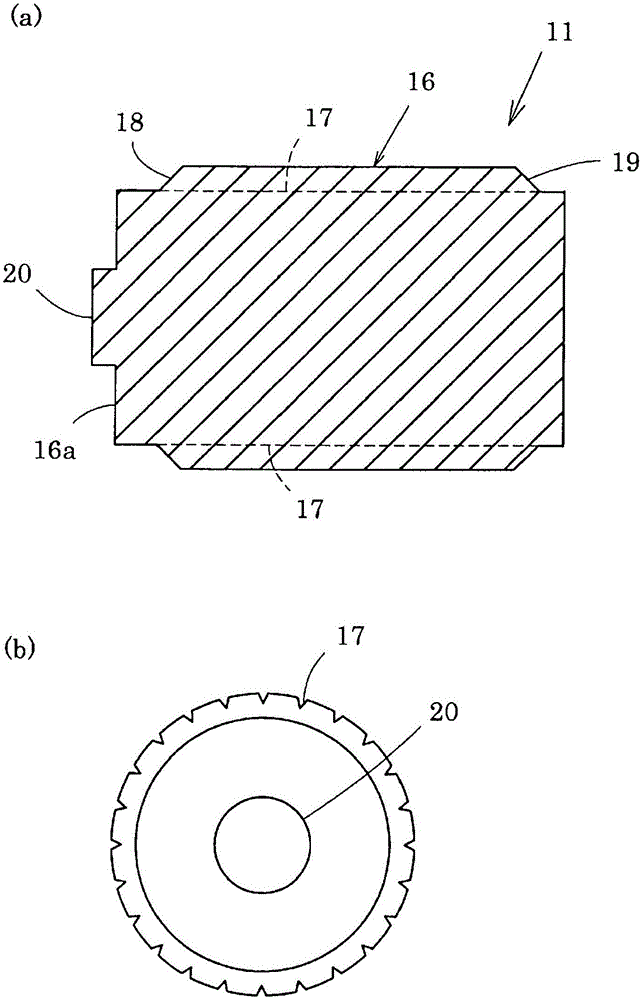

[0068] Protruding portion 20 of core 11: outer diameter 1.5 mm, height 0.2 mm

[0069] Recess 26 of nozzle member 12: inner diameter 2.0 mm, height 0.4 mm, nozzle diameter 0.15 mm

[0070] Passage (groove 27): width 0.15mm, depth 0.2mm, 4 (passage area: 0.12mm 2 )

[0071] In this spout mechanism 10, the outer diameter of the protruding portion 20 is 75% of the inner diameter of the recessed portion 26, the height of the protruding portion 20 is 50% of the height of the recessed portion 26, and the area ratio of the passage to the spout is 6.8.

Embodiment 2

[0073] Protruding portion 20 of core 11: outer diameter 1.5 mm, height 0.05 mm

[0074] Recess 26 of nozzle member 12: inner diameter 2.0 mm, height 0.4 mm, nozzle diameter 0.15 mm

[0075] Passage (groove 27): width 0.15mm, depth 0.2mm, 4 (passage area: 0.12mm 2 )

[0076] In this spout mechanism 10, the outer diameter of the protruding portion 20 is 75% of the inner diameter of the recessed portion 26, the height of the protruding portion 20 is 15% of the height of the recessed portion 26, and the area ratio of the passage to the spout is 6.8.

Embodiment 3

[0078] Protrusion 20 of core 11: inner diameter 0.75mm, height 0.2mm

[0079] Recess 26 of nozzle member 12: inner diameter 2.0 mm, height 0.4 mm, nozzle diameter 0.15 mm

[0080] Passage (groove 27): width 0.15mm, depth 0.2mm, 4 (passage area: 0.12mm 2 )

[0081] In this spout mechanism 10, the outer diameter of the protruding portion 20 is 37.5% of the inner diameter of the recessed portion 26, the height of the protruding portion 20 is 50% of the height of the recessed portion 26, and the area ratio of the passage to the spout is 6.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com