Power generation element and power generation apparatus provided with power

A technology of power generation components and magnetostrictive rods, applied in the direction of electrical components, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problems of low power generation efficiency and achieve power generation Multiple and durable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

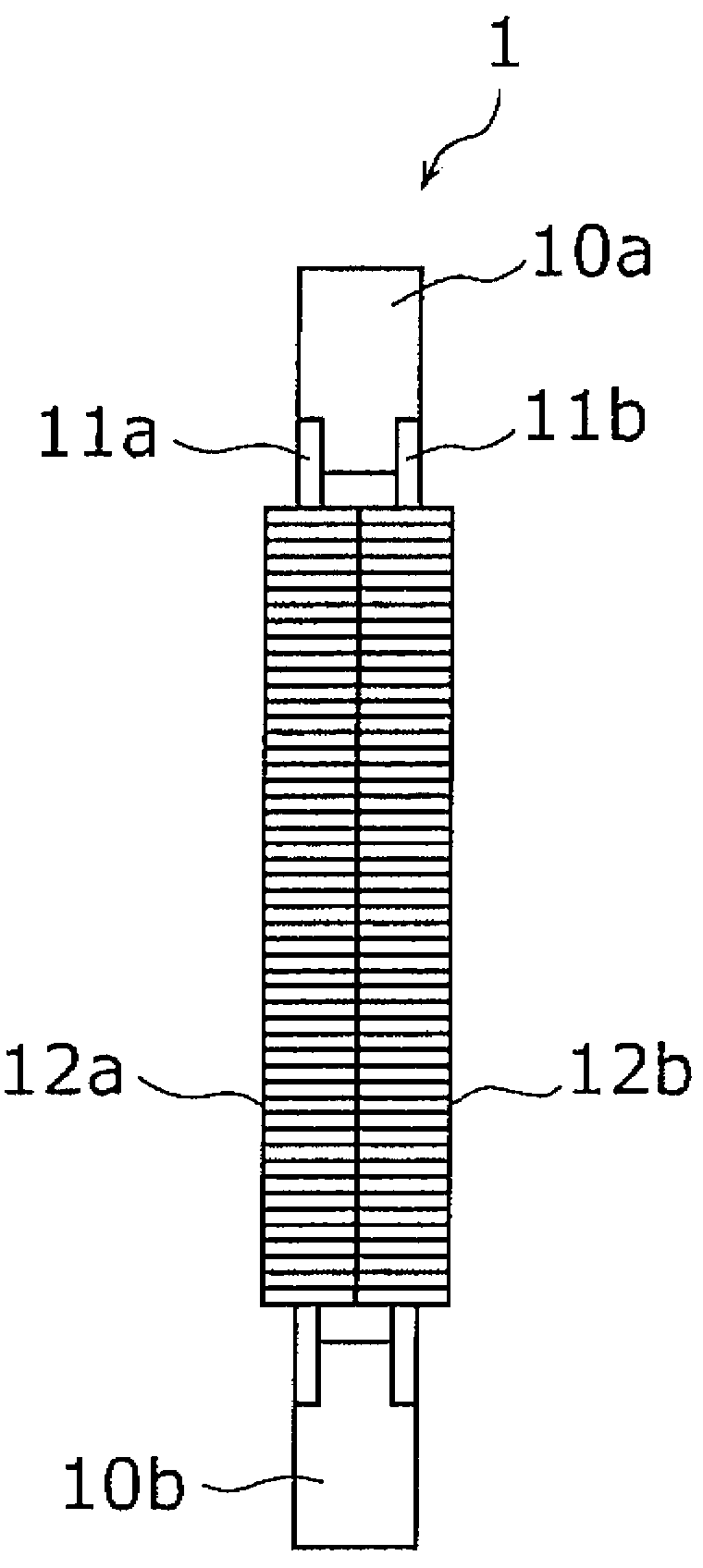

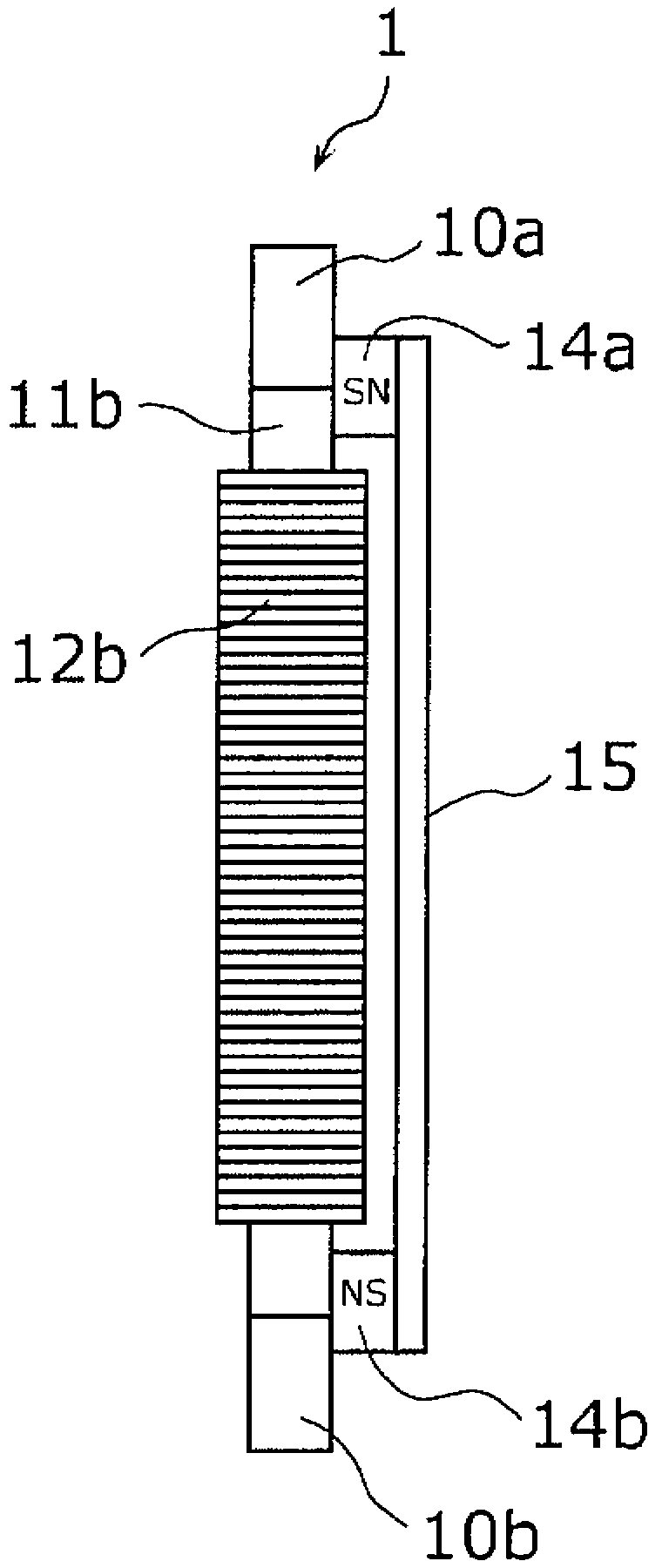

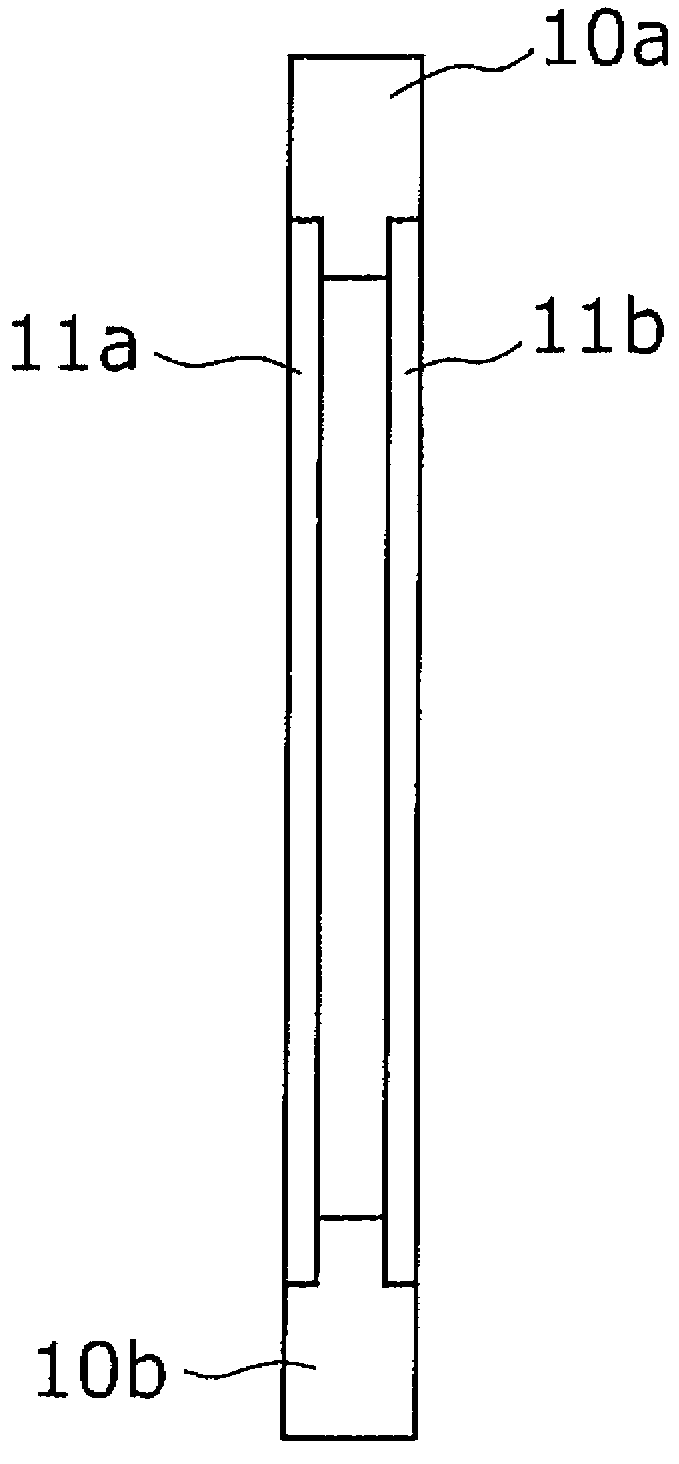

[0109] Figure 1A is a plan view of a power generating element according to an embodiment of the present invention, Figure 1B It is a side view of the power generating element according to one embodiment of the present invention. Such as Figure 1A and Figure 1BAs shown, the power generating element 1 includes connection yokes 10 a and 10 b , magnetostrictive rods 11 a and 11 b , coils 12 a and 12 b , permanent magnets 14 a and 14 b , and a back yoke 15 .

[0110] Figure 2A and Figure 2B yes means Figure 1A and Figure 1B A schematic diagram of the arrangement positions of the magnetostrictive rods 11a and 11b and the connecting yokes 10a and 10b of the power generating element 1 shown, Figure 2A and Figure 2B corresponding to Figure 1A and Figure 1B .

[0111] The magnetostrictive rods 11 a and 11 b are made of, for example, Galfenol which is an iron-gallium alloy, have ductility, and each have a rectangular parallelepiped rod shape of 1 mm×0.5 mm×10 mm.

[0...

Embodiment approach 2

[0186] Next, Embodiment 2 which is one embodiment of the present invention will be described. In Embodiment 1 described above, the power generating element is constituted by two magnetostrictive rods, but this embodiment is different from Embodiment 1 in that the power generating element is constituted by one magnetostrictive rod and a connecting yoke.

[0187] Figure 11A is a side view of the power generating element of this embodiment, Figure 11B yes means Figure 11A A side view of the arrangement position of the magnetostrictive rod and the connecting yoke of the power generating element shown.

[0188] Such as Figure 11A As shown, the power generating element of this embodiment includes a magnetostrictive rod 11c, a connecting yoke 10c, and a coil 12c. In addition, the magnetostrictive rod 11c and the coil 12c correspond to the 1st magnetostrictive rod and the 1st coil of this invention, respectively.

[0189] The magnetostrictive rod 11c is the same as the magnet...

Embodiment approach 3

[0194] Next, Embodiment 3 which is one embodiment of the present invention will be described. In this embodiment, a power generating element in which a plurality of coils are wound in parallel around each magnetostrictive rod will be described. Figure 12A ~ Figure 12D is a plan view of the power generating element of this embodiment, Figures 13A-13G yes Figure 12A ~ Figure 12D Equivalent circuit diagram of the power generating element shown. In addition, in Figure 12A ~ Figure 12D In , the coils 12a and 12b are shown as cross-sectional views.

[0195] Figure 12A The power generating element 1 shown is with Figure 1A The power generating element 1 shown has the same structure, and the basic structure of the power generating element 1 is shown. In this power generating element 1, one coil 12a and 12b are respectively wound around the magnetostrictive rods 11a and 11b. According to this configuration, by dividing the coils and connecting them in parallel, it is possib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com