Deoiler

A technology of deoiling machine and outer cylinder, which is applied to centrifuges and centrifuges with rotating drums, etc., which can solve problems such as unstable operation of the machine, increased noise, deformation of the inner cylinder, etc., and achieve long service life and not easy The effect of deformation and not easy to shake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

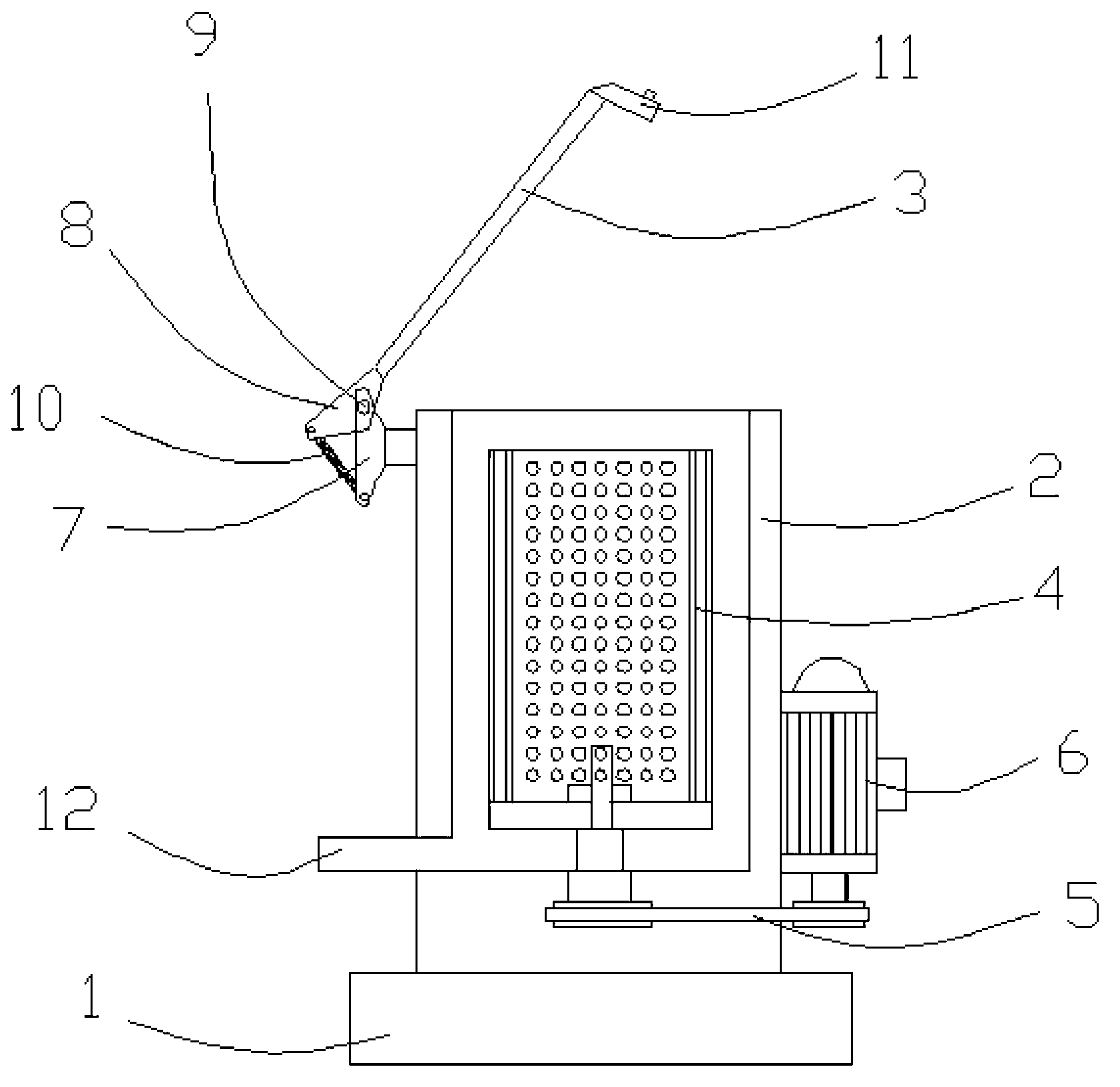

[0011] Such as figure 1 As shown, a deoiling machine includes a base 1, an outer cylinder 2 arranged above the base 1, a cylinder cover 3 arranged above the outer cylinder 2, an inner cylinder 4 arranged inside the outer cylinder 2, and a belt drive below the inner cylinder 4 5 The motor 6 is connected. The inner cylinder 4 has two layers of iron with small holes on the inner cylinder wall. The upper outer cylinder wall of the outer cylinder 2 is provided with a cover seat 7, and the cylinder cover 3 is provided with a cover bracket 8, and a cover seat 7 and the cover bracket 8 are connected by a rotating shaft 9 and a spring 10. The cylinder cover 3 is also provided with a lock 11. An oil outlet 12 is provided on the lower side wall of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com